Monel Machining: Guide, Types, and Difficulties

Monel, a nickel-copper alloy, is renowned for its exceptional corrosion resistance and high strength, making it a preferred material in industries such as aerospace, marine, and chemical processing. However, machining Monel presents unique challenges due to its hardness, work-hardening tendencies, and low thermal conductivity. This guide provides a detailed exploration of Monel machining, including its types, techniques, and specific difficulties, with technical parameters to ensure precision and efficiency.

Understanding Monel Alloys

Monel alloys primarily consist of nickel (52–67%) and copper (20–31.5%), with trace amounts of iron, manganese, carbon, and silicon. These alloys are designed for harsh environments, offering resistance to seawater, acids, and high temperatures up to 1000°F (538°C). The most common Monel alloys used in machining are:

- Monel 400: A versatile alloy with excellent corrosion resistance, used in marine and chemical applications.

- Monel 401: Designed for electronics, offering good brazing qualities and low Curie temperature.

- Monel 405: A free-machining grade with higher sulfur content, ideal for automatic screw machines.

- Monel K-500: Enhanced with titanium and aluminum for higher strength and hardness, used in oil-well drill collars and marine pump shafts.

Each alloy variant requires specific machining considerations due to differences in composition and mechanical properties, such as hardness (70–95 HRB) and tensile strength (550–1100 MPa).

Machining Techniques for Monel

Machining Monel requires specialized techniques to address its unique properties. Below are the primary methods used, along with detailed parameters for optimal performance.

Turning

Turning Monel involves using lathes to shape cylindrical parts. Due to Monel’s work-hardening nature, slow cutting speeds and sharp tools are essential to prevent excessive heat buildup and tool wear.

| Parameter | Monel 400 | Monel K-500 |

|---|---|---|

| Cutting Speed (m/min) | 60–100 | 50–80 |

| Feed Rate (mm/rev) | 0.1–0.2 | 0.08–0.15 |

| Depth of Cut (mm) | 0.25–1.0 | 0.2–0.8 |

| Tool Material | Carbide | Carbide |

Use high-speed steel (HSS) or carbide-tipped tools with a positive rake angle (0° to 5°) to minimize cutting forces. Apply ample coolant, such as C-5200 cutting fluid, to reduce heat and improve surface finish.

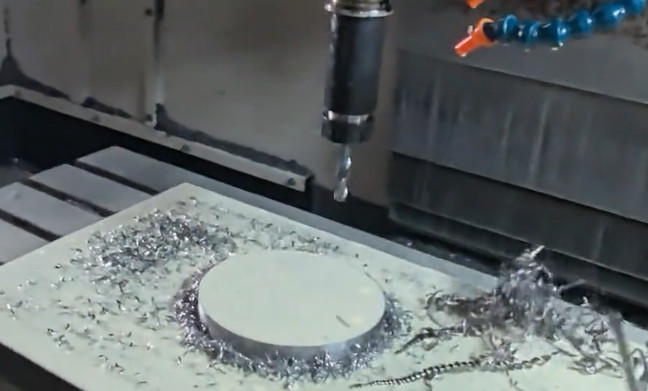

Milling

Milling Monel requires multi-axis CNC machines for complex geometries. The alloy’s low thermal conductivity leads to heat concentration at the cutting edge, necessitating robust cooling systems.

- Cutting Speed: 50–80 m/min for Monel 400; 40–70 m/min for Monel K-500.

- Feed Rate: 0.05–0.15 mm/tooth.

- Depth of Cut: 0.5–2.0 mm for roughing; 0.1–0.5 mm for finishing.

- Tool Geometry: Use carbide end mills with a helix angle of 30°–45° to reduce vibration.

Employ climb milling to minimize work-hardening and ensure chip evacuation. Coolants should be applied at high pressure to dissipate heat effectively.

Drilling

Drilling Monel is challenging due to its tendency to form built-up edges (BUE). Use cobalt or carbide drills with a 118°–135° point angle and a split-point geometry to enhance chip breaking.

- Cutting Speed: 20–40 m/min.

- Feed Rate: 0.05–0.1 mm/rev for diameters up to 10 mm; 0.1–0.2 mm/rev for larger diameters.

- Coolant: High-pressure soluble oil or synthetic coolant to prevent tool adhesion.

Peck drilling is recommended to clear chips and prevent work-hardening. Maintain a consistent feed to avoid dwell times that increase heat generation.

Non-Conventional Machining

For intricate shapes or microchannels, non-conventional methods like Wire Electrical Discharge Machining (WEDM) and Photochemical Machining (PCM) are effective.

- WEDM Parameters: Pulse-on time (10–50 µs), pulse-off time (20–60 µs), gap voltage (40–60 V), wire feed (2–8 m/min), and dielectric flow rate (5–15 L/min).

- PCM Parameters: Etchant temperature (40–60°C), etching time (10–50 min), and ferric chloride concentration (30–40%).

WEDM achieves dimensional accuracy within 6% for microchannels, while PCM is suitable for thin sheets (0.025–2 mm) but requires careful control to minimize undercut.

Difficulties in Machining Monel

Monel’s properties, while advantageous for end-use applications, create significant machining challenges. Below are the primary difficulties encountered:

Work-Hardening

Monel rapidly work-hardens during machining, increasing its hardness and making subsequent cuts more difficult. This phenomenon is pronounced in Monel K-500 due to its higher strength (tensile strength: 900–1100 MPa). To mitigate this, use sharp tools, low cutting speeds, and light depths of cut. Roughing cuts should remove material incrementally, followed by finishing cuts to achieve dimensional accuracy.

Low Thermal Conductivity

Monel’s low thermal conductivity (21.8 W/m·K for Monel 400) causes heat to concentrate at the cutting zone, accelerating tool wear and degrading surface quality. High-pressure coolants and optimized cutting parameters are critical to dissipate heat. For example, a cutting speed of 100 m/min with a feed rate of 0.15 mm/rev reduces thermal impact in Monel 400.

Tool Wear

The abrasive nature of Monel, combined with high cutting temperatures, leads to rapid tool wear mechanisms such as abrasion, adhesion, and diffusion. Carbide tools with hardness above 2000 HV10 are recommended, as they offer 30% higher wear resistance than standard grades. Regular tool inspection and replacement are necessary to maintain machining efficiency.

Built-Up Edge (BUE) Formation

BUE occurs when Monel adheres to the cutting tool, increasing cutting forces and surface roughness. This is exacerbated by the alloy’s high ductility. Using positive rake angles and high-pressure lubricants minimizes BUE. For instance, MQL + CO₂ cooling reduces BUE by 19.58% compared to dry cutting.

Surface Quality Issues

Achieving a smooth surface finish (Ra < 1.6 µm) is difficult due to Monel’s tendency to form micro-scratches and adhesion marks. Optimal parameters, such as a cutting speed of 78.35 m/min and feed rate of 0.1 mm/rev, can reduce surface roughness by up to 47.19% when using hybrid MQL + CO₂ cooling.

Best Practices for Machining Monel

To overcome Monel’s machining difficulties, adhere to the following best practices:

- Tool Selection: Use carbide or cobalt tools with sharp edges and positive rake angles to reduce cutting forces.

- Cutting Parameters: Maintain low cutting speeds (50–100 m/min) and feed rates (0.1–0.2 mm/rev) to minimize work-hardening and heat generation.

- Coolant Application: Employ high-pressure coolants or hybrid MQL + CO₂ systems to control heat and reduce tool wear.

- Machine Setup: Use rigid CNC machines with multi-axis capabilities to ensure precision and stability during complex operations.

- Tool Maintenance: Regularly inspect and replace tools to prevent degradation of surface quality and dimensional accuracy.

These practices, when combined with precise parameter control, enhance machining efficiency and part quality.

Applications of Machined Monel Parts

Monel’s properties make it ideal for demanding applications. Machined Monel parts are used in:

- Aerospace: Components like fasteners and turbine blades requiring high strength and heat resistance.

- Marine: Pump shafts, valves, and fittings exposed to seawater.

- Chemical Processing: Reactors and piping systems handling corrosive substances.

- Oil and Gas: Drill collars and extraction well components operating in high-pressure environments.

Precision machining ensures these components meet strict tolerances (e.g., ±0.01 mm) and perform reliably under extreme conditions.

Comparison of Monel Alloys for Machining

| Alloy | Hardness (HRB) | Machinability Rating | Primary Applications |

|---|---|---|---|

| Monel 400 | 70–80 | 45% | Marine, chemical processing |

| Monel 405 | 75–85 | 50% | Automatic screw machines |

| Monel K-500 | 80–95 | 40% | Oil wells, marine pump shafts |

Monel 405 offers the highest machinability due to its sulfur content, while Monel K-500 is the most challenging due to its enhanced hardness.

Conclusion

Machining Monel requires a deep understanding of its properties, precise parameter control, and specialized techniques. By using appropriate tools, optimizing cutting conditions, and applying effective cooling strategies, manufacturers can overcome difficulties such as work-hardening, tool wear, and poor surface quality. This guide provides a systematic approach to Monel machining, ensuring high-quality results for critical applications in aerospace, marine, and chemical industries.

FAQs About Monel

What is Monel?

Monel is a family of nickel-copper alloys known for their exceptional corrosion resistance, high strength, and durability in harsh environments. The most common grade, Monel 400, typically contains 65-70% nickel, 20-29% copper, and small amounts of iron, manganese, and other elements. Developed by the International Nickel Company (Inco) in the early 20th century, Monel alloys are valued for their performance in marine, chemical, and industrial applications.

What are the key properties of Monel alloys?

Corrosion resistance: Excellent resistance to seawater, brines, acids (e.g., sulfuric acid), and alkaline solutions.

High strength: Maintains strength at both high and low temperatures (up to ~480°C / 900°F).

Ductility: Can be easily formed, welded, and machined (though some grades require specialized techniques).

Resistance to oxidation: Performs well in high-temperature, oxidizing environments compared to many other nickel alloys.

What are the most common grades of Monel?

Monel 400: The original and most widely used grade, ideal for marine and chemical processing.

Monel K-500: A precipitation-hardened version of Monel 400, offering higher strength and wear resistance (often used in valves and pumps).

Monel R-405: A free-machining variant of Monel 400, designed for easier fabrication of small parts.

How does Monel compare to stainless steel?

Superior resistance to seawater, sulfuric acid, and chloride-induced pitting (stainless steel may corrode in such environments).

Higher nickel content (enhances ductility and high-temperature performance).

Generally higher strength than most stainless steels, especially at elevated temperatures.

However, Monel is more expensive than stainless steel, so cost often dictates material choice for less demanding applications.

Can Monel be welded or machined?

Yes, but with considerations:

Welding: Monel can be welded using techniques like gas tungsten arc welding (GTAW/TIG) or shielded metal arc welding (SMAW), but requires clean surfaces and compatible filler metals to avoid porosity.

Machining: Monel is somewhat gummy and work-hardens quickly, so sharp tools, slow speeds, and ample coolant are recommended. Free-machining grades (e.g., R-405) reduce these challenges.