Diamond-Like Carbon (DLC) coatings are advanced thin-film materials that combine the desirable properties of diamond and graphite. These coatings are widely used across industries due to their exceptional hardness, low friction, and resistance to wear and corrosion. This article provides a detailed, technical examination of DLC coatings, including their composition, properties, deposition methods, applications, and specific parameters. The content is structured to offer a systematic and professional understanding for engineers, researchers, and industry professionals.

Composition and Structure of DLC Coatings

DLC coatings are amorphous carbon films characterized by a mix of sp² (graphite-like) and sp³ (diamond-like) carbon bonds. The ratio of sp³ to sp² bonds, along with the presence of hydrogen or other elements, determines the coating's properties. DLC exists in multiple forms, including hydrogenated (a-C:H) and non-hydrogenated (a-C or ta-C) variants. Tetrahedral amorphous carbon (ta-C) is considered the "purest" form, consisting primarily of sp³ bonds, resembling the structure of diamond.

The amorphous nature of DLC coatings results from random alternations between cubic and hexagonal lattices, eliminating long-range crystalline order. This structure prevents brittle fracture planes, making DLC coatings flexible yet extremely hard. The incorporation of dopants such as silicon, nitrogen, or metals like tungsten or chromium can modify properties like hardness, electrical conductivity, or thermal stability.

Key Structural Parameters

The performance of DLC coatings depends on several structural parameters:

- sp³/sp² Ratio: Higher sp³ content increases hardness and wear resistance, with ta-C coatings achieving up to 90% sp³ bonding.

- Hydrogen Content: Hydrogenated DLC (a-C:H) typically contains 10–50% hydrogen, affecting lubricity and thermal stability.

- Density: DLC coatings have densities values ranging from 1.8 to 3.2 g/cm³, with ta-C approaching diamond’s density of ~3.5 g/cm³.

- Thickness: Typical DLC coatings range from 1–4 microns, balancing performance and residual stress.

Properties of DLC Coatings

DLC coatings are valued for their multifunctional properties, making them suitable for demanding applications. Below are the primary properties, supported by specific parameters.

Mechanical Properties

DLC coatings exhibit exceptional mechanical performance due to their high sp³ content. Hardness is a critical attribute, often measured using nanoindentation techniques. For example, ta-C coatings can achieve a microhardness of 5000–8000 HV, surpassing many conventional ceramic coatings like TiN or CrN. The elastic modulus typically ranges from 200–600 GPa, depending on the sp³/sp² ratio.

The low coefficient of friction (COF) is another hallmark, with values as low as 0.05–0.15 in dry conditions against steel. This lubricity reduces energy loss in mechanical systems. Wear resistance is equally impressive, with wear rates as low as 7 x 10⁻¹⁷ m³/N·m in tribological tests.

Chemical and Thermal Properties

DLC coatings are chemically inert, resisting corrosion from acids, alkalis, and bodily fluids in biomedical applications. They also provide a gas barrier effect, useful in sealing applications. However, thermal stability is limited, with most DLC coatings degrading above 300–400°C due to graphitization of sp³ bonds. Doping with silicon or adjusting the sp³/sp² ratio can enhance thermal stability to some extent.

Thermal conductivity varies widely, from 1 W/m·K for hydrogenated DLC to 1000 W/m·K for ta-C, depending on structure and composition.

Optical and Electrical Properties

DLC coatings offer high optical transparency across visible and infrared wavelengths, making them ideal for optical components. Their refractive index ranges from 1.8 to 2.4, and they exhibit low infrared absorption. Electrically, DLC coatings are typically insulating due to sp³ bonding, but doping with nitrogen or metals can adjust conductivity for specific applications.

| Property | Parameter | Description |

|---|---|---|

| Hardness | 2000–8000 HV | Measured via nanoindentation; ta-C achieves highest values. |

| Coefficient of Friction | 0.05–0.15 | Low COF in dry conditions against steel. |

| Wear Rate | ~7 x 10⁻¹⁷ m³/N·m | Excellent wear resistance in tribological applications. |

| Thermal Stability | Up to 300–400°C | Limited by graphitization; doping improves stability. |

| Optical Transparency | Visible to IR | Suitable for optical systems with low absorption. |

Deposition Methods for DLC Coatings

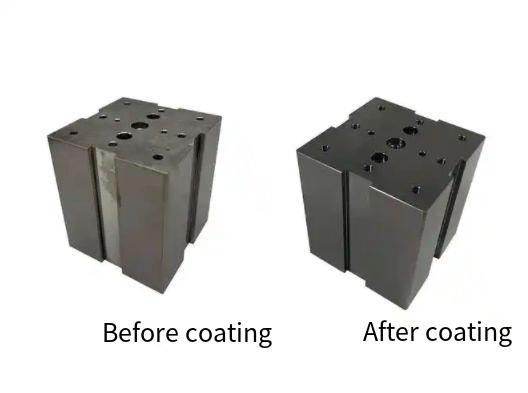

DLC coatings are applied using various deposition techniques, each influencing the coating’s properties. The choice of method depends on the substrate, application, and desired characteristics.

Physical Vapor Deposition (PVD)

PVD methods, such as sputtering and cathodic arc evaporation, involve vaporizing solid carbon and depositing it onto a substrate in a vacuum. Sputtering produces uniform coatings but may result in lower sp³ content. Cathodic arc deposition achieves higher sp³ ratios (up to 90% in ta-C) due to high-energy ion bombardment, with ion energies typically ranging from 10–300 eV.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

PECVD uses hydrocarbon gases (e.g., methane, acetylene) in a plasma environment to deposit DLC films. The process operates at low temperatures (100–250°C), making it suitable for temperature-sensitive substrates like plastics. PECVD allows precise control of hydrogen content, with deposition rates of 0.1–1 µm/hour.

Other Methods

Additional techniques include ion beam deposition and pulsed laser deposition. Ion beam deposition offers excellent control over film thickness and uniformity, while pulsed laser deposition is used for high-purity ta-C coatings. Each method requires careful calibration of parameters like substrate bias voltage, ion energy, and gas composition to achieve desired properties.

| Method | Temperature (°C) | sp³ Content | Applications |

|---|---|---|---|

| PVD Sputtering | 100–200 | Moderate (40–60%) | Decorative coatings, optics |

| Cathodic Arc | 100–300 | High (70–90%) | High-wear components, tools |

| PECVD | 100–250 | Variable (20–80%) | Automotive, biomedical |

| Ion Beam Deposition | 50–150 | High (60–85%) | Optical coatings, precision parts |

Applications of DLC Coatings

DLC coatings are employed across diverse industries due to their versatile properties. Below are key application areas with specific examples.

Automotive Industry

In automotive applications, DLC coatings reduce friction and wear in engine components like piston pins, tappets, and diesel injection systems. For instance, DLC-coated piston rings achieve a wear reduction of up to 80% compared to uncoated counterparts, enhancing fuel efficiency and component lifespan.

Biomedical Applications

DLC coatings are biocompatible and hemocompatible, making them ideal for medical implants and tools. They reduce wear in orthopedic implants and minimize thrombogenicity in cardiovascular stents. The coatings’ chemical inertness ensures compatibility with bodily fluids, with no cytotoxicity observed in cell tests.

Optical and Electronics

DLC coatings enhance the durability of optical components, such as infrared windows and lenses, due to their transparency and scratch resistance. In electronics, they protect against wear and corrosion in connectors and hard disk heads, with a typical coating thickness of 1–2 microns.

Aerospace and Tooling

In aerospace, DLC coatings protect components from extreme wear and corrosion in harsh environments. For cutting tools, they extend tool life by up to 10 times compared to uncoated tools, particularly in machining composites or sticky materials.

Technical Considerations

While DLC coatings offer significant advantages, certain technical considerations must be addressed to ensure optimal performance. Adhesion to substrates can be a limitation due to high residual stresses in DLC films, often exceeding 5 GPa. This issue is mitigated by using multilayer stacks, such as titanium or chromium adhesion layers, which reduce stress concentrations and improve bonding. Another consideration is the low thermal stability of DLC coatings, which limits their use in high-temperature environments above 400°C. Careful selection of deposition parameters and dopants can address these constraints to some extent.

Conclusion

Diamond-Like Carbon (DLC) coatings are a cornerstone of modern surface engineering, offering a unique combination of hardness, low friction, and chemical inertness. Their amorphous structure, tunable sp³/sp² ratio, and compatibility with various deposition methods make them versatile for applications in automotive, biomedical, optical, and aerospace industries. By understanding the technical parameters and deposition techniques, engineers can optimize DLC coatings for specific requirements, ensuring enhanced performance and durability. This comprehensive overview serves as a valuable resource for professionals seeking to implement DLC coatings in their projects.