Automotive precision machining is a cornerstone of modern vehicle manufacturing, enabling the production of high-quality components with exacting tolerances. This article provides a detailed examination of the processes, materials, applications, and technical specifications involved in automotive precision machining, emphasizing its critical role in ensuring performance, safety, and reliability in the automotive industry.

Overview of Automotive Precision Machining

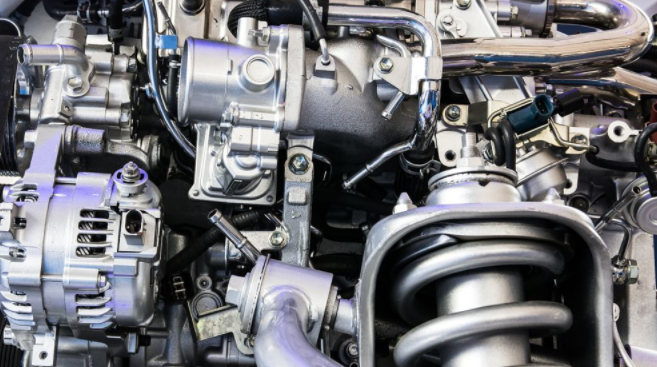

Automotive precision machining involves the use of advanced manufacturing techniques to produce components with tight tolerances, typically ranging from 0.1 to 10 micrometers (μm), and surface roughness below 0.1 μm. These components, such as engine parts, transmission gears, and suspension systems, are essential for vehicle functionality. The process integrates computer numerical control (CNC) machines, advanced tooling, and quality control systems to achieve consistent accuracy and repeatability. Precision machining is distinguished by its ability to meet stringent automotive standards, including IATF 16949, which mandates rigorous quality control and continuous improvement.

The primary goal is to manufacture parts that meet exact specifications for dimensions, surface finish, and material properties. This is achieved through processes like turning, milling, grinding, and drilling, often performed on multi-axis CNC machines. These machines use pre-programmed instructions to control cutting tools, ensuring high precision and minimal waste. The automotive industry relies on these techniques to produce components that withstand extreme conditions, such as high temperatures and mechanical stress, while maintaining performance and durability.

Key Processes in Automotive Precision Machining

Several machining processes are employed to meet the automotive industry’s demands for precision and efficiency. Each process is tailored to specific component requirements and material properties. Below is a detailed overview of the primary processes used.

CNC Turning

CNC turning is used to produce cylindrical components such as shafts, gears, and hubs. The workpiece rotates while a cutting tool removes material to achieve the desired shape. Modern CNC turning machines, equipped with multi-axis capabilities, can achieve dimensional accuracies of ±0.005 mm. For example, in the production of crankshafts, CNC turning ensures precise journal diameters (e.g., 50 ± 0.01 mm) and surface finishes with roughness values as low as Ra 0.8 μm. The process is highly automated, reducing human error and enabling high-volume production with consistent quality.

CNC Milling

CNC milling is employed for complex geometries, such as engine blocks and cylinder heads. The process uses rotating multi-point cutting tools to remove material from a stationary workpiece. Five-axis CNC milling machines allow for intricate features, such as cooling channels in engine blocks, with tolerances as tight as ±0.002 mm. For instance, milling an aluminum engine block may involve a spindle speed of 12,000 RPM, a feed rate of 2,000 mm/min, and a depth of cut of 0.5 mm to achieve optimal surface quality and dimensional accuracy.

Grinding

Grinding is a finishing process used to achieve ultra-smooth surfaces and tight tolerances, particularly for components like bearings and camshafts. It employs abrasive wheels to remove small amounts of material, achieving surface roughness as low as Ra 0.1 μm. For example, cylindrical grinding of a steel camshaft may use a wheel speed of 30 m/s and a workpiece rotation of 100 RPM to ensure precise lobe profiles. Grinding is critical for components requiring minimal friction and wear resistance.

Drilling

Drilling creates precise holes in components such as engine blocks and transmission cases. CNC drilling machines use high-speed steel or carbide drills to achieve hole diameters with tolerances of ±0.01 mm. For instance, in brake caliper manufacturing, drilling ensures mounting holes with positional accuracy of 0.02 mm, critical for proper assembly and braking performance. Coolant systems are often employed to manage heat and extend tool life during high-speed drilling.

Materials Used in Automotive Precision Machining

Material selection is critical in automotive precision machining, as it directly impacts component performance, durability, and machinability. The following table summarizes common materials and their applications.

| Material | Properties | Applications | Machining Considerations |

|---|---|---|---|

| Aluminum Alloys | Lightweight, high strength-to-weight ratio, corrosion-resistant | Engine blocks, cylinder heads, body panels | High-speed machining, coolant required to prevent galling |

| Steel and Stainless Steel | High strength, durability, corrosion resistance (stainless) | Chassis, gears, exhaust systems | Lower cutting speeds, robust tooling to handle hardness |

| Titanium | High strength, low density, corrosion-resistant | Connecting rods, valves | Low thermal conductivity, requires specialized tooling |

| Plastics and Composites | Lightweight, versatile, corrosion-resistant | Interior components, body panels | Low cutting forces, dust extraction needed |

Each material requires specific machining parameters to optimize performance. For example, machining aluminum alloys at high speeds (e.g., 15,000 RPM) reduces cutting forces but necessitates effective chip evacuation to prevent tool clogging. Steel, due to its hardness, requires slower speeds (e.g., 8,000 RPM) and robust carbide tools to maintain tool life.

Applications in the Automotive Industry

Precision machining is integral to various automotive systems, ensuring components meet strict performance and safety standards. Below are key applications, detailing their technical requirements.

Engine Components

Engine components, such as pistons, crankshafts, and camshafts, require exceptional precision to ensure efficient combustion and power delivery. For instance, pistons are machined to tolerances of ±0.005 mm to ensure proper fit within cylinder bores. Surface finishes of Ra 0.4 μm are achieved through grinding to minimize friction and wear. CNC milling and turning are used to create complex features like oil galleries and valve seats, with positional accuracies of 0.01 mm.

Transmission Systems

Transmission components, including gears and shafts, demand high precision to ensure smooth power transfer. CNC turning produces gear teeth with profile accuracies of ±0.003 mm, while grinding ensures surface roughness below Ra 0.2 μm. For example, a gearbox shaft may be machined with a spindle speed of 10,000 RPM and a feed rate of 1,500 mm/min to achieve the required dimensional accuracy and surface quality.

Suspension and Steering Systems

Suspension and steering components, such as control arms and tie rods, require precise machining to ensure vehicle stability and handling. CNC milling creates mounting points with tolerances of ±0.01 mm, while drilling ensures accurate bolt holes. For instance, a steering knuckle may require a surface finish of Ra 0.8 μm to reduce wear in high-stress contact areas.

Brake Systems

Brake components, such as calipers and rotors, are machined to ensure reliable stopping power. CNC milling produces caliper bodies with dimensional tolerances of ±0.005 mm, while grinding achieves rotor surface finishes of Ra 0.3 μm to ensure consistent braking performance. Positional accuracy of mounting holes is critical to prevent vibration and ensure proper alignment.

Quality Control and Inspection

Ensuring component accuracy is paramount in automotive precision machining. Advanced quality control systems, such as coordinate measuring machines (CMM), are used to verify dimensions with accuracies of ±0.001 mm. For example, a CMM may measure the bore diameter of a cylinder head to ensure it meets a specification of 85 ± 0.005 mm. Optical microscopy and 3D scanning detect surface defects and verify tolerances, while statistical process control (SPC) monitors production consistency. Regular machine calibration against known standards ensures long-term accuracy.

Cleanliness is another critical consideration, particularly for transmission and engine components. Automated optical microscopy (AOM) systems detect contaminants as small as 10 μm, ensuring parts meet stringent cleanliness standards. For instance, Ford’s transmission contamination labs use AOM to analyze debris, ensuring compliance with specifications that limit metallic particles to less than 0.1 mg per component.

Technical Specifications and Parameters

The following table outlines typical machining parameters for common automotive components, illustrating the precision required.

| Component | Process | Tolerance (mm) | Surface Roughness (Ra, μm) | Spindle Speed (RPM) | Feed Rate (mm/min) |

|---|---|---|---|---|---|

| Crankshaft | Turning | ±0.005 | 0.8 | 8,000 | 1,200 |

| Engine Block | Milling | ±0.002 | 0.4 | 12,000 | 2,000 |

| Camshaft | Grinding | ±0.003 | 0.1 | 10,000 | 1,000 |

| Brake Caliper | Drilling | ±0.01 | 0.8 | 6,000 | 800 |

These parameters are adjusted based on material properties and component requirements. For instance, titanium components require lower cutting speeds (e.g., 4,000 RPM) due to their low thermal conductivity, while aluminum allows higher speeds for faster material removal.

Conclusion

Automotive precision machining is a critical discipline that ensures the production of high-quality, reliable components for modern vehicles. Through processes like CNC turning, milling, grinding, and drilling, manufacturers achieve tolerances as tight as ±0.002 mm and surface finishes below Ra 0.1 μm. Material selection, quality control, and precise machining parameters are integral to meeting the automotive industry’s stringent standards. By leveraging advanced CNC technology and rigorous inspection methods, precision machining supports the production of safe, efficient, and durable vehicles.