In modern manufacturing, the machining of thin-walled parts remains a significant challenge in the field of numerical control (NC) technology. Owing to their complex structures and proneness to deformation due to thin walls, the machining process of thin-walled parts often encounters multiple challenges in fixture design and process control. To efficiently and accurately complete the machining of thin-walled parts, NC technology requires comprehensive consideration and adjustments from multiple aspects, including fixture design, machining processes, and process optimization.

Difficulties and Challenges in Thin-Walled Part Machining

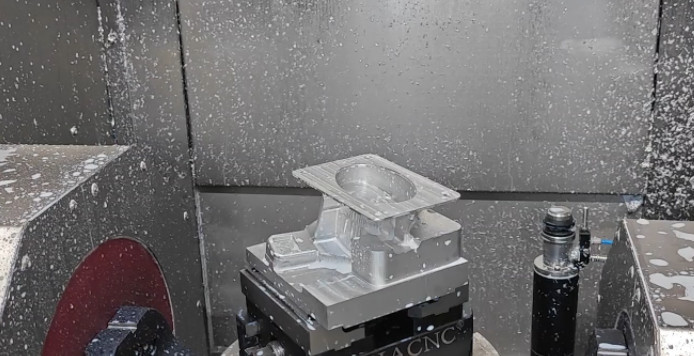

Thin-walled parts typically feature a small wall thickness and a large size ratio, which makes them susceptible to deformation during CNC machining. Due to the weak nature of their thin walls, traditional clamping methods may exert excessive force on the workpiece, leading to workpiece deformation and compromising machining accuracy and surface quality. Additionally, the machining of thin-walled parts imposes high requirements on cutting force, tool selection, feed rate, and other parameters—even minor improper operations can affect the final machining result. Therefore, addressing the fixture and process issues of thin-walled parts has become a major challenge in NC machining.

Key Issues in Fixture Design

Fixture design is particularly critical for the machining of thin-walled parts. Traditional fixtures usually adopt a fixed clamping method, which works well for thick-walled part machining. However, in thin-walled part machining, excessively strong clamping force can cause workpiece deformation. To avoid this problem, fixture design in NC technology must pay special attention to the following aspects:

- Selection of Clamping Methods: To prevent excessive clamping force from affecting the workpiece, fixture design should consider the use of flexible clamping methods, such as pneumatic fixtures or hydraulic fixtures. These types of fixtures can adjust the clamping force according to the shape and characteristics of the workpiece, ensuring that the workpiece is firmly clamped without causing deformation.

- Selection of Fixture Materials: To ensure that the fixture has sufficient rigidity to withstand the cutting forces generated during machining, fixture materials need to possess high strength and wear resistance. At the same time, the weight of the material should also be considered to avoid imposing additional loads on the machine tool.

- Optimization of Fixture Structure: Thin-walled parts often have irregular shapes, so the fixture structure needs to be customized based on the workpiece’s characteristics. For example, structures such as multi-point clamping or annular support can be used to ensure uniform distribution of clamping force and reduce the risk of workpiece deformation.

Process Challenges and Countermeasures

In the machining process of thin-walled parts, the key lies in controlling cutting force, feed rate, and machining accuracy. Due to the special properties of thin-walled parts, excessive cutting force or improper tool selection may cause workpiece deformation and affect machining quality. Therefore, a reasonable machining process is crucial for solving the challenges in thin-walled part machining.

- Control of Cutting Force: During thin-walled part machining, cutting force is a major factor affecting workpiece deformation. To reduce cutting force, methods such as low cutting depth and small feed rate can be adopted to avoid excessive cutting force leading to workpiece deformation. In addition, cutting fluids can be used to cool the tool and workpiece, reducing thermal deformation during the cutting process.

- Tool Selection and Adjustment: Tool selection is vital for thin-walled part machining. Generally, choosing sharp tools with high rigidity can effectively reduce cutting force. Meanwhile, the tool’s installation angle should be adjusted according to the shape and characteristics of the workpiece to avoid deformation caused by improper tool cutting.

- Optimization of Machining Paths: In the machining process of thin-walled parts, the design of NC programs also requires special attention. A reasonable machining path can effectively disperse cutting force and reduce friction between the tool and the workpiece, thereby preventing deformation of thin-walled parts. Especially for thin-walled parts with complex shapes, the design of a reasonable machining sequence and path is particularly important.

Advantages and Applications of Modern NC Technology

With the continuous development of NC technology, many new machining technologies and methods have been introduced into the machining of thin-walled parts. These new technologies provide more options for the efficient machining of thin-walled parts.

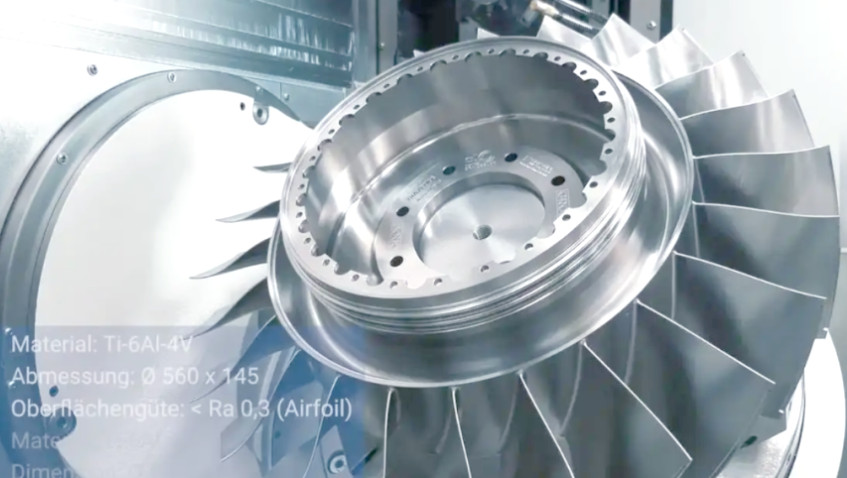

- 5-Axis Machining Technology: 5-axis machining technology can perform machining in multiple directions simultaneously, greatly improving machining accuracy and efficiency. For thin-walled parts with complex shapes, 5-axis machining technology can effectively reduce the deformation problems that may occur in traditional machining methods.

- High-Speed Cutting Technology: High-speed cutting technology can complete the machining of thin-walled parts in a shorter time while reducing the impact of cutting force on the workpiece. When combined with high-precision NC machine tools, it can ensure high precision and surface quality in thin-walled part machining.

- Automated Fixtures and Robot Assistance: With the development of industrial automation technology, many modern automated fixtures and robot-assisted systems have been applied in the machining of thin-walled parts. These technologies can effectively improve production efficiency and ensure the stability and accuracy of the machining process.

Conclusion

Due to their unique structural characteristics and high-precision requirements, the machining of thin-walled parts has long been a major challenge in NC technology. To improve the efficiency and accuracy of thin-walled part machining, fixture design and process optimization are particularly important. By reasonably selecting fixtures, optimizing machining process paths, controlling cutting force, and introducing advanced NC technology, the fixture and process challenges in thin-walled part machining can be effectively addressed. With the continuous development of NC technology, the machining of thin-walled parts will become more efficient and precise in the future, providing higher-quality machining solutions for various industries.