Precision prototype machining transforms conceptual designs into tangible, high-accuracy components using advanced manufacturing processes. This guide explores the core techniques, materials, and applications of precision prototype machining, focusing on CNC technology, material selection, and quality control. Designed for engineers, procurement managers, and manufacturers, this content provides a detailed, technical overview to support informed decision-making in prototype development.

Understanding Precision Prototype Machining

Precision prototype machining refers to the process of creating highly accurate, functional prototypes using computer numerical control (CNC) machines and other advanced manufacturing technologies. These prototypes serve as critical tools for testing form, fit, and function before full-scale production. The process is widely used across industries such as automotive, aerospace, medical, and electronics, where exact specifications and tight tolerances are non-negotiable.

The primary goal is to produce prototypes that mirror the final product's performance while allowing for iterative design improvements. By leveraging CNC machining, manufacturers can achieve tolerances as tight as ±0.005 inches, ensuring reliability and consistency. This section outlines the foundational elements of the process, including equipment, software, and workflow.

CNC Machining in Prototyping

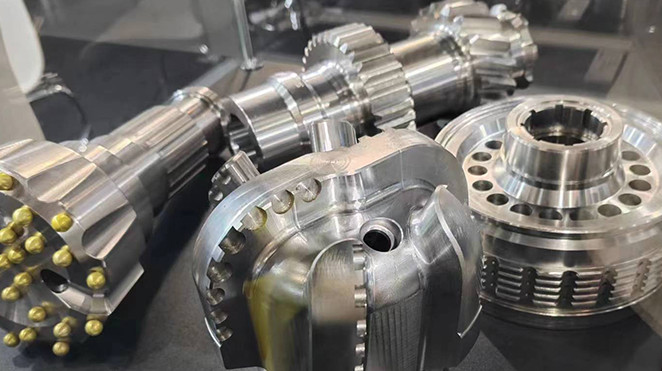

CNC machining is the cornerstone of precision prototype machining. It involves the use of computer-controlled tools to remove material from a workpiece, creating precise components. CNC machines operate on multiple axes—typically 3, 4, or 5 axes—allowing for complex geometries and intricate designs.

Key CNC processes include:

- Milling: Uses rotating cutting tools to remove material from a stationary workpiece. Suitable for flat surfaces, slots, and complex contours.

- Turning: Rotates the workpiece against a stationary cutting tool, ideal for cylindrical parts like shafts and rings.

- Drilling: Creates precise holes with controlled depth and diameter, often used for mounting or assembly features.

- Grinding: Achieves fine surface finishes, with surface roughness as low as Ra 0.4μm, critical for medical and aerospace components.

5-axis CNC machines enhance precision by allowing simultaneous movement along five axes, reducing setup times and enabling complex shapes. For example, a medical device prototype with a surface finish requirement of Ra ≤ 0.4μm can be machined in a single setup, minimizing errors.

Software and Design Integration

Precision machining begins with computer-aided design (CAD) software, such as SolidWorks or AutoCAD, to create detailed 3D models. These models are converted into machine-readable instructions using computer-aided manufacturing (CAM) software, which generates NC code for CNC machines. Key considerations include:

- Geometric Accuracy: Ensuring the CAD model aligns with machining capabilities to avoid errors.

- Process Features: Adding positioning holes or clamping surfaces to facilitate machining.

- Toolpath Optimization: CAM software optimizes toolpaths to reduce machining time and tool wear, improving efficiency.

Simulation tools within CAM software allow manufacturers to verify toolpaths and detect potential collisions before machining begins, ensuring error-free production.

Material Selection for Precision Prototypes

Choosing the right material is critical for prototype performance and manufacturability. The material must meet functional requirements, such as strength, corrosion resistance, or weight, while being compatible with CNC machining processes. Below is a table summarizing common materials used in precision prototype machining, along with their properties and applications.

| Material | Properties | Applications | Machining Considerations |

|---|---|---|---|

| Aluminum Alloy (6061, 7075) | Lightweight, high strength-to-weight ratio, corrosion-resistant | Aerospace components, automotive parts, consumer electronics | Easy to machine, low tool wear, cost-effective |

| Stainless Steel (304, 316) | High corrosion resistance, durable | Medical devices, industrial equipment | Higher tool wear, requires optimized cutting parameters |

| Titanium Alloy (Ti-6Al-4V) | High strength, lightweight, biocompatible | Medical implants, aerospace structures | Difficult to machine, requires low cutting speeds |

| Engineering Plastics (PEEK, ABS) | Lightweight, chemical-resistant, flexible | Prototypes for electronics, medical housings | Requires precise temperature control to avoid melting |

Material selection impacts machining parameters, such as cutting speed, feed rate, and tool type. For instance, titanium alloys require slower cutting speeds (30–50 m/min) compared to aluminum (200–300 m/min) to prevent excessive heat buildup and tool wear.

Quality Control in Precision Machining

Quality control ensures prototypes meet stringent specifications, particularly in industries like aerospace and medical, where deviations can lead to catastrophic failures. Precision machining shops employ advanced metrology tools and processes to validate part accuracy.

Metrology and Inspection

Metrology labs use tools like coordinate measuring machines (CMMs), laser scanners, and X-ray inspection to verify dimensional accuracy and surface quality. Key parameters include:

- Tolerance: Ensuring parts meet tolerances as tight as ±0.005 inches.

- Surface Finish: Measuring roughness (Ra) to ensure compliance with specifications, e.g., Ra ≤ 0.4μm for medical implants.

- Material Integrity: Using X-ray or ultrasonic testing to detect internal defects.

Climate-controlled metrology labs maintain temperature, humidity, and dust levels to ensure measurement accuracy, especially for micron-level tolerances.

Process Validation

Process validation involves documenting every step of the machining process to ensure repeatability. This includes:

- Tool Calibration: Regular calibration of CNC tools to maintain accuracy.

- Process Documentation: Creating detailed process specifications, including clamping methods and toolpaths.

- Traceability: Tracking materials and processes to ensure compliance with industry standards, such as ISO 9001 or AS9100.

For example, in medical prototype machining, every part must be traceable to its raw material batch, with documented validation of the machining process.

Applications Across Industries

Precision prototype machining supports a wide range of industries by enabling rapid development and testing of components. Below are key applications, with specific examples of how machining meets industry needs.

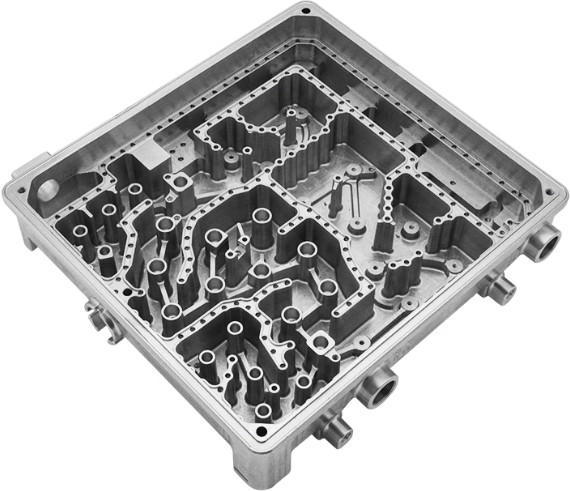

Automotive

Automotive prototypes, such as engine blocks or gearbox shells, require high precision and durability. CNC machining enables rapid production, with lead times as short as 3 days for complex components. Materials like aluminum and stainless steel are commonly used for their strength and weight advantages.

Aerospace

Aerospace prototypes demand tight tolerances (e.g., ±0.002 inches) and lightweight materials like titanium. CNC machining produces structural components and turbine blades with complex geometries, ensuring compliance with stringent standards like AS9100.

Medical

Medical prototypes, such as surgical rasps or implants, require biocompatible materials and ultra-smooth surfaces (Ra ≤ 0.4μm). 5-axis CNC machining ensures precision for patient-specific implants, often guided by CT or MRI scans.

Electronics

Electronics prototypes, like mobile phone shells or circuit board enclosures, benefit from CNC machining’s ability to achieve high-gloss finishes and fine textures. Materials like ABS and aluminum are popular for their aesthetic and functional properties.

Key Considerations for Effective Prototyping

To maximize the benefits of precision prototype machining, manufacturers must address several considerations to ensure efficiency and quality.

Design for Manufacturability (DFM)

DFM involves designing parts to optimize machining efficiency. This includes minimizing complex features that require multiple setups, selecting materials that balance performance and machinability, and incorporating features like chamfers to reduce post-processing.

Lead Time and Scalability

Rapid prototyping with CNC machining can deliver parts in as little as 2–3 days, but scaling to production requires planning. Manufacturers should select partners with capabilities for both low-volume prototyping and high-volume production, ensuring seamless transitions.

Cost Optimization

Cost considerations include material selection, machining time, and post-processing. For example, using aluminum instead of titanium can reduce costs by up to 50% for non-critical applications, while optimizing toolpaths can lower machining time by 20–30%.

FAQ

What is precision prototype machining?

Precision prototype machining uses CNC technology to create high-accuracy prototypes for testing form, fit, and function before production.

What materials are used in precision machining?

Common materials include aluminum, stainless steel, titanium, and engineering plastics like PEEK, chosen based on application needs.

How accurate is CNC machining for prototypes?

CNC machining achieves tolerances as tight as ±0.005 inches, with surface finishes as fine as Ra 0.4μm, depending on equipment and materials.