Precision Machining Services

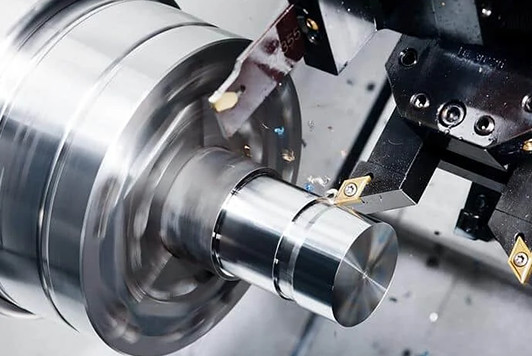

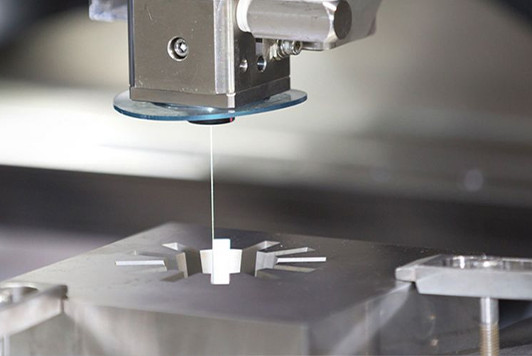

KeSu offers advanced CNC machining, Swiss machining, turning, milling, and multi-axis machining with a strong focus on tight tolerances (±0.005mm or better) and high-quality finishes.

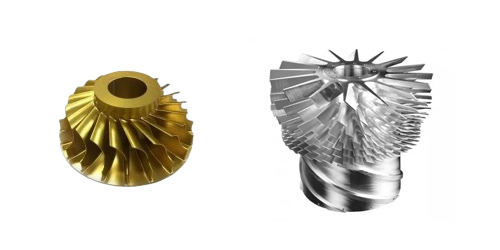

CNC precision machining is essential for producing detailed and complex designs that regular machining can’t achieve. It allows for consistent production of high-quality precision machined parts and components, such as impellers, gears, brackets, and enclosures.Whether it’s small-scale prototypes or large-volume production, we deliver durable and dependable components. KeSu is committed to providing comprehensive high precision machining solutions to meet the diverse needs of our clients across various industries.

Types of Precision Machining That We Offer

Why Choose Us

1

High Quality Parts

Kesu guarantees exceptional prototype quality by employing high-grade materials and precise craftsmanship, all while strictly complying with industry standards.

2

Fast Lead Time

Our streamlined processes ensure rapid prototype delivery, greatly reducing development cycles and accelerating time to market.

3

Engineering Support

Kesu offers comprehensive engineering support, helping optimize designs and overcome technical challenges to enhance prototype development.

We've helped thousands of customers succeed

Thomas

Sales Manager

Addison.H

Head of Designer

Nancy. K

Engineer

He is my long term supplier with all my trust.

Can we please proceed the order for parts as quoted? Drawings and quote attached.

How it Works

Upload a CAD File

To begin, just provide some basic details and upload a 3D CAD file.

Quote & Design Analysis

You’ll quickly receive a quote, along with a design for manufacturability (DFM) analysis if needed.

Order Confirmation

After you approve the quote and submit your order, we’ll begin production. Finishing options are also available.

Parts Are Shipped

Your prototypes or custom parts will be thoroughly inspected and shipped directly to you.

Precision Machining FAQ

When to choose precision machining?

What materials can be used with precision machining?

How can Kesu guarantee tight tolerances?

Let's Build Something Great, Together

Complete CNC machining services from prototype to production ensure high quality, fast delivery. Great Teamwork, Motivated Staff, Consistently Delivering Excellent Work For Our Customers. Kesu is a top-notch custom parts manufacturing provider offering high-quality and CNC precision machining services. In CNC precision machining Kesu is among the top manufacturer of machine parts all over the world and in China they are the top 5 best service providers of CNC precision machining parts.