Our Blog

Latest articles

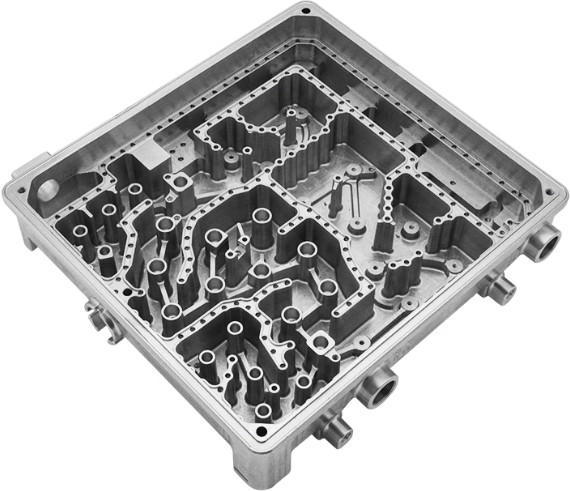

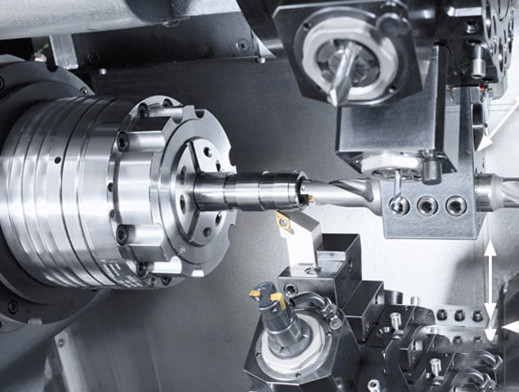

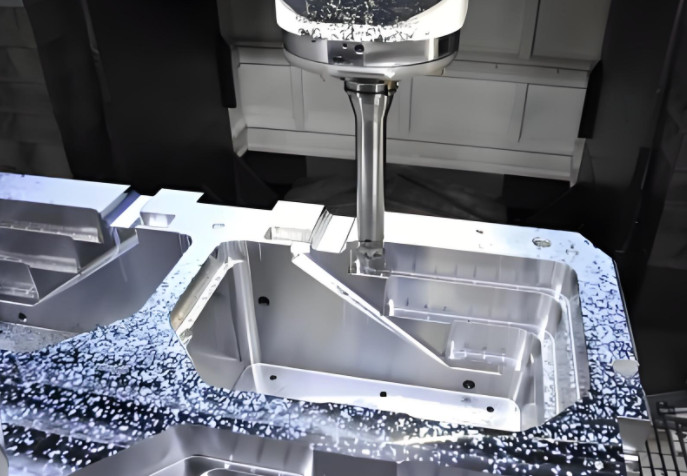

Precision Prototype Machining: Techniques and Applications

Explore precision prototype machining: advanced CNC techniques, material options, and high-accuracy processes for custom prototypes. Get insights into efficient, reliable solutions for your manufacturing needs.

Thin-Walled Part Machining: Fixtures and Process Challenges

To complete the machining of thin-walled parts, CNC technology requires multiple aspects, including fixture design, machining processes, and process optimization.

CNC machining for aerospace components: how to select material

Material selection fundamentally dictates the outcomes of CNC machining for aerospace components, as it influences the part’s performance, machining complexity, cost, and service life.

CNC Machining Surface Roughness: How to choose

Choosing the appropriate CNC machining surface roughness is crucial for ensuring performance, cost-effectiveness, and suitability for the target application.

Why Hex Flange Nuts Resist Compression Better Than Standard Nuts

Hex flange nuts look similar to ordinary hex nuts, but their load-bearing performance is markedly better. The advantage comes from their structural design and the

Machining Sheet Metal: Techniques, Tools, and Processes

Explore sheet metal machining: master techniques like cutting, bending, and stamping. Learn tools, processes, and parameters for high-precision fabrication.

How Much Is a CNC Machine for Metal

Discover the cost of CNC machines for metal in recent years. Explore factors affecting prices, machine types, and tips to choose the right one for

CNC Metal Machining: Precision and Performance

Explore CNC metal machining: precision processes, materials, and applications for high-quality components in industries like aerospace and automotive.

Superalloy Machining: Challenges, Technologies, and Applications

Superalloys(high-performance alloys), their superior high-temperature properties make them extremely difficult to machine compared to conventional metals (e.g., aluminum, low-carbon steel).

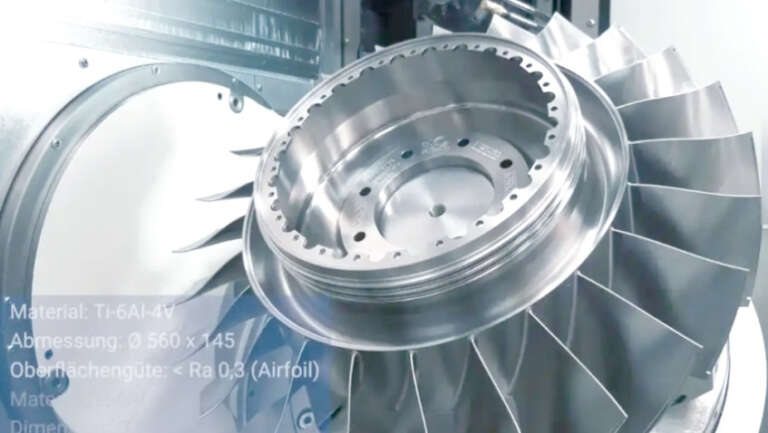

Turbine Blades Machining: A Comprehensive Guide

Turbine blades are critical core components in aerospace engines, gas turbines, and steam turbines turbomachinery. Their machining is extremely challenging due to strict requirements on

CNC Machining Cost Reduction Tips

CNC Machining Cost Reduction Made Easy: 10 Key Tips—From Raw Materials to Bulk Orders. Cut Time & Expenses, Get Precision Parts.

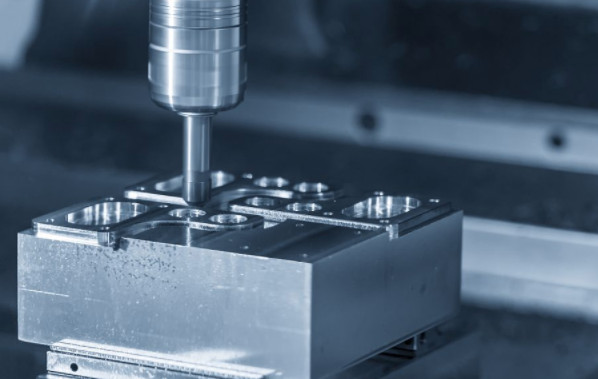

Machining Accuracy

Master machining accuracy: Learn its definition, tolerance grades (IT01-IT18), 3 core types (dimensional/shape/position accuracy), error causes & 7 adjustment methods + measurement techniques—essential for precision

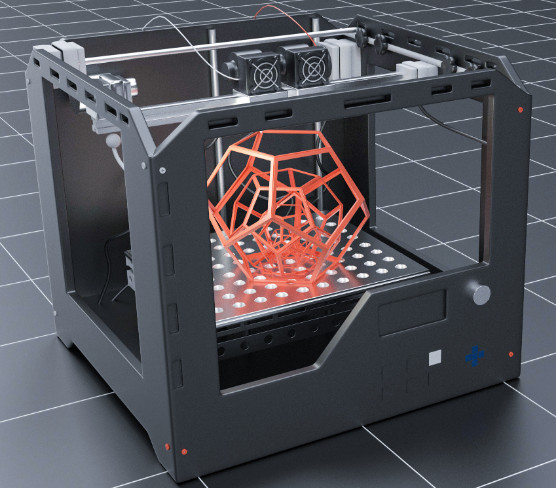

3D printing images

Present many free 3D printable models images for you to explore. All 3D models on our site are 100% free to download with no restrictions,

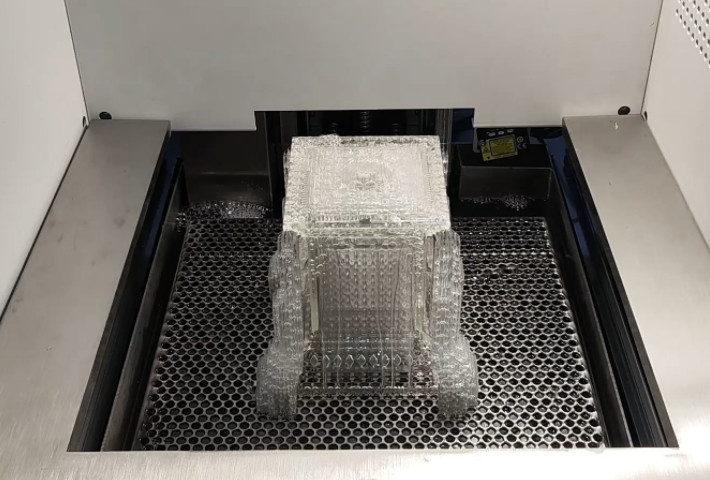

SLA 3D Printing: Technology and Applications

Explore SLA 3D printing: a comprehensive guide to stereolithography technology, its process, materials, applications, and technical specifications for professional use.

Guide Vanes: Design and Function in Turbomachinery

Explore guide vanes in turbomachinery: their design, function, and performance impact. Learn key parameters and applications for optimal efficiency.

Precision Machining Guide

Explore our comprehensive Precision Machining Guide to master techniques, tools, and processes. Learn about CNC machining, tolerances, materials, and more to achieve high-accuracy components.

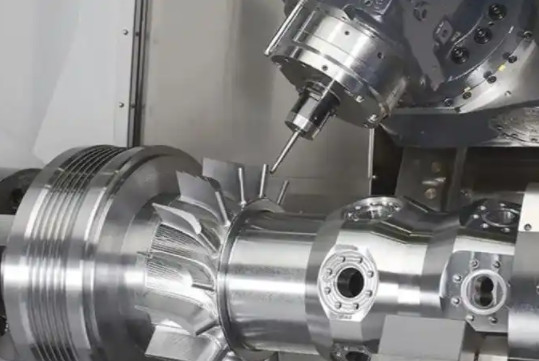

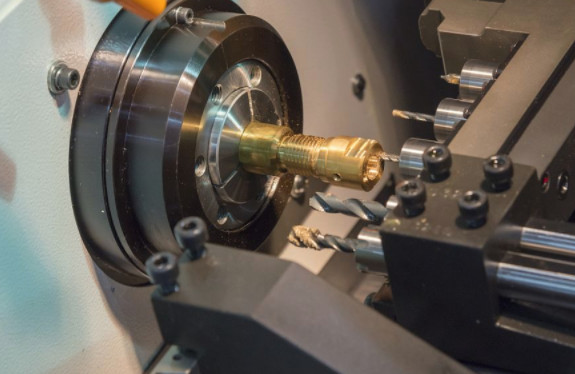

Metal CNC Machining

Unlock unparalleled precision and efficiency. Our definitive guide to metal CNC machining covers everything from core processes and materials to industrial applications. Master the technology

Rapid CNC Machining: Speed and Precision Guide

Discover rapid CNC machining: a high-speed, precise manufacturing process for prototypes and small-batch parts. Learn about processes, materials, tolerances, and applications.

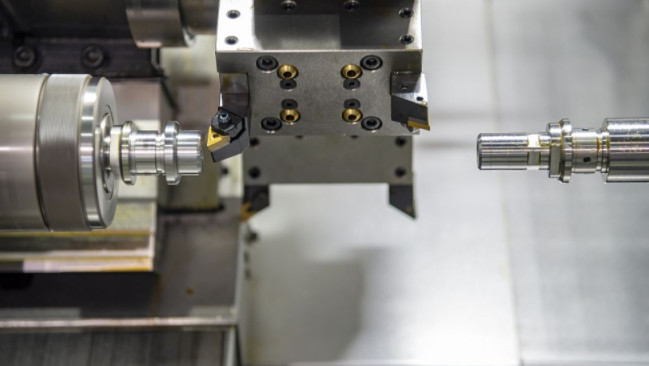

Metal Machining: Processes, Types, and Applications

Metal machining stands as a cornerstone of subtractive manufacturing, a process where material is systematically removed from a workpiece to achieve precise shapes, dimensions, and

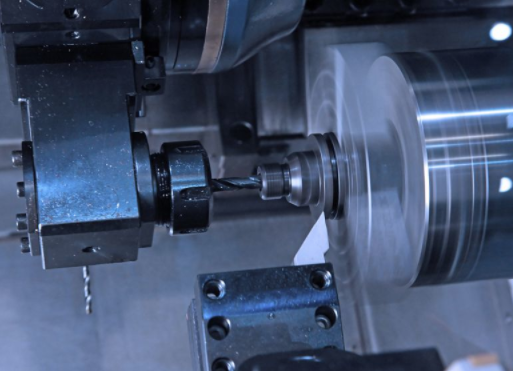

Machine Cutter Metal: Essential Technical Guide

Unlock precision in metal fabrication with our in-depth guide to machine cutters for metal. Explore types, technical parameters, operational principles, and key selection factors to

Metal CNC Machine: Precision and Efficiency

Discover how metal CNC machines deliver precision and efficiency in manufacturing. Explore key features, applications, and technical specifications for optimal performance.

Micron Precision Machining: Techniques and Applications

Explore micron precision machining techniques, equipment, materials, and applications for high-accuracy components in medical, aerospace, and automotive sectors.

Ultra Precision Machining Principles and Practices

Ultra precision machining delivers sub-micrometer accuracy and nanometer surface finishes for optical, mechanical, and semiconductor components using advanced diamond tools and controlled environments

2017 Aluminum Alloy: Properties and Applications

2017 aluminum, a 2000-series wrought alloy, is a high-strength, heat-treatable material widely used in industries requiring robust mechanical properties, such as aerospace and automotive. This