C51900, a phosphor bronze alloy, is a copper-based material known for its high strength, corrosion resistance, and excellent spring properties. This alloy, primarily composed of copper, tin, and phosphorus, is widely used in industries requiring durable, conductive, and wear-resistant materials. This article provides a detailed examination of C51900, covering its composition, mechanical and physical properties, applications, manufacturing processes, and key considerations for its use. The content is structured to offer a comprehensive, technical overview for professionals seeking to understand or utilize this alloy.

Composition and Standards of C51900

C51900 is a phosphor bronze alloy defined by the Copper Development Association (CDA) and adheres to ASTM standards, specifically ASTM B103/B103M for plate, sheet, strip, and rolled bar. The alloy’s composition is carefully balanced to achieve desired mechanical and physical properties. Below is a detailed breakdown of its chemical makeup:

| Element | Percentage (%) |

|---|---|

| Copper (Cu) | Balance (93.6–94.8) |

| Tin (Sn) | 5.0–7.0 |

| Phosphorus (P) | 0.03–0.35 |

| Zinc (Zn) | 0.30 max |

| Iron (Fe) | 0.10 max |

| Lead (Pb) | 0.05 max |

The high copper content provides excellent electrical and thermal conductivity, while tin enhances strength and corrosion resistance. Phosphorus improves wear resistance and stiffness, making C51900 ideal for spring applications. Trace elements like zinc, iron, and lead are limited to ensure purity and performance. Compliance with ASTM B103 ensures consistent quality across manufacturers.

Mechanical Properties

The mechanical properties of C51900 make it suitable for demanding applications. These properties vary depending on the temper (e.g., annealed, half-hard, hard), which is controlled during manufacturing. Below is a table summarizing key mechanical properties for common tempers:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| Annealed | 310–450 | 110–200 | 40–60 | 80–100 |

| Half-Hard | 450–620 | 300–500 | 15–30 | 120–150 |

| Hard | 620–830 | 500–700 | 5–15 | 150–180 |

Tensile strength and yield strength increase with harder tempers, while elongation decreases, reflecting reduced ductility. Hardness also increases with temper, making hard-temper C51900 suitable for high-wear applications. These properties make C51900 versatile for components requiring both strength and flexibility, such as springs and connectors.

A key consideration is the trade-off between strength and formability. Hard tempers, while stronger, are less malleable, which can complicate forming processes. Engineers must select the appropriate temper based on the application’s requirements for strength versus ease of fabrication.

Physical Properties

C51900’s physical properties contribute to its widespread use in electrical and mechanical applications. Key physical properties include:

- Density: 8.86 g/cm³

- Electrical Conductivity: Approximately 15% IACS (International Annealed Copper Standard)

- Thermal Conductivity: 66 W/m·K at 20°C

- Melting Point: Approximately 950–1050°C

- Modulus of Elasticity: 110 GPa

The alloy’s density is slightly higher than pure copper due to tin and phosphorus additions. Its electrical conductivity, while lower than pure copper, is sufficient for many electrical applications, such as connectors and terminals. Thermal conductivity supports heat dissipation in components like heat exchangers. The high modulus of elasticity ensures excellent spring properties, allowing C51900 to maintain shape under repeated loading.

A practical consideration is the alloy’s moderate electrical conductivity. For applications requiring higher conductivity, pure copper or other alloys like C51000 may be preferred. However, C51900’s balance of conductivity and strength often makes it a better choice for components under mechanical stress.

Applications of C51900

C51900’s combination of strength, corrosion resistance, and formability makes it suitable for a wide range of applications. Common uses include:

- Electrical Connectors and Terminals: The alloy’s conductivity and spring properties ensure reliable electrical connections in automotive, aerospace, and telecommunications industries.

- Springs and Diaphragms: High yield strength and elasticity make C51900 ideal for springs in switches, relays, and precision instruments.

- Marine Hardware: Corrosion resistance, particularly in saltwater environments, suits C51900 for marine fittings and fasteners.

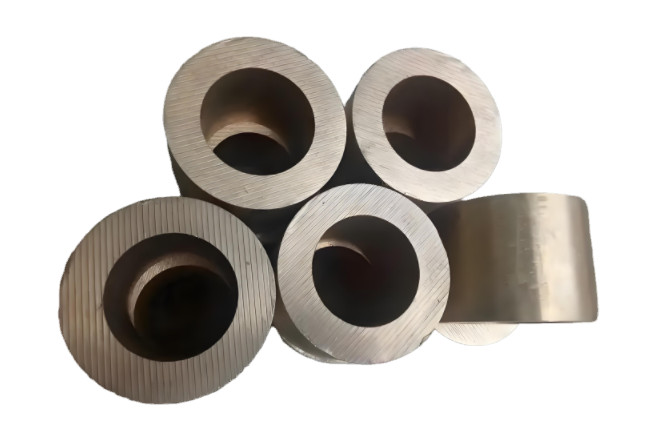

- Wear-Resistant Components: Phosphorus enhances wear resistance, making the alloy suitable for bushings, bearings, and gears.

- Musical Instruments: C51900 is used in components like reeds and strings due to its acoustic properties and durability.

A consideration in applications is the alloy’s cost. C51900 is more expensive than brass or pure copper due to its tin content and processing requirements. Engineers must weigh cost against performance when selecting materials for high-volume production.

Manufacturing Processes

C51900 is typically supplied in forms such as sheet, strip, plate, or wire, manufactured through processes like casting, rolling, and annealing. Key manufacturing steps include:

- Melting and Casting: Copper, tin, and phosphorus are melted in precise proportions and cast into ingots or billets.

- Rolling: The cast material is hot- or cold-rolled into sheets or strips, with thickness controlled to meet ASTM specifications.

- Annealing: Heat treatment relieves internal stresses and adjusts mechanical properties, producing tempers from annealed to extra-hard.

- Forming and Machining: C51900 can be stamped, bent, or drawn into complex shapes. Its machinability is moderate, requiring sharp tools and proper lubrication.

A manufacturing consideration is the alloy’s work-hardening behavior. Cold working increases strength but reduces ductility, potentially leading to cracking during forming if not carefully managed. Annealing may be required between forming steps to restore workability.

Corrosion Resistance and Environmental Considerations

C51900 exhibits excellent corrosion resistance, particularly in marine and industrial environments. The tin content enhances resistance to dezincification and stress corrosion cracking, while phosphorus improves resistance to wear and oxidation. The alloy performs well in:

- Marine Environments: Resists saltwater corrosion, making it suitable for shipbuilding and offshore applications.

- Industrial Atmospheres: Withstands exposure to acids, alkalis, and atmospheric pollutants.

- High-Humidity Conditions: Maintains integrity in humid environments without significant tarnishing.

A limitation is that C51900 may corrode in highly acidic or ammoniacal environments. Protective coatings or alternative alloys may be needed in such cases. Additionally, recycling C51900 is straightforward, as copper-based alloys are highly recyclable, reducing environmental impact.

Welding and Joining

C51900 can be joined using various methods, though some techniques are more effective than others:

- Soldering: Excellent results with standard solders due to the alloy’s copper base.

- Brazing: Suitable with proper flux and filler materials, though care is needed to avoid overheating.

- Welding: Gas tungsten arc welding (GTAW) and resistance welding are effective, but oxyacetylene welding is not recommended due to potential cracking.

- Mechanical Fastening: Riveting and bolting are viable for components requiring disassembly.

A consideration is the risk of porosity in welds if phosphorus content is not carefully controlled. Proper joint preparation and welding parameters are critical to avoid defects.

Comparison with Other Alloys

C51900 is often compared to other phosphor bronzes like C51000 and C52100. Key differences include:

- C51000: Lower tin content (4.2–5.8%) results in slightly lower strength but better formability.

- C52100: Higher tin content (7.0–9.0%) offers greater strength but reduced ductility.

C51900 strikes a balance between these alloys, offering a combination of strength, corrosion resistance, and formability. However, for applications requiring higher conductivity, alloys like C11000 (pure copper) may be considered, though they lack C51900’s mechanical strength.

Key Considerations for Selection

When selecting C51900, engineers should evaluate:

- Application Requirements: Balance strength, conductivity, and corrosion resistance against cost.

- Manufacturing Constraints: Consider work-hardening and forming limitations.

- Environmental Exposure: Ensure compatibility with operating conditions.

Conclusion

C51900 phosphor bronze is a versatile alloy with a unique combination of strength, corrosion resistance, and electrical conductivity. Its composition, mechanical and physical properties, and manufacturing characteristics make it a preferred choice for applications ranging from electrical connectors to marine hardware. By understanding its properties and limitations, engineers can optimize its use in demanding environments. Proper selection of temper and joining methods, along with consideration of cost and environmental factors, ensures C51900 delivers reliable performance across industries.