Polishing vacuum pump aluminum alloy blades is a critical process to ensure smooth operation, reduce friction, and enhance durability. However, micro scratches often appear during polishing, compromising surface quality and performance. This article examines the causes of micro scratches and provides practical, evidence-based solutions to achieve a high-quality finish. With a focus on technical precision and systematic approaches, the content draws from industry practices to offer reliable guidance.

Understanding Micro Scratches in Blade Polishing

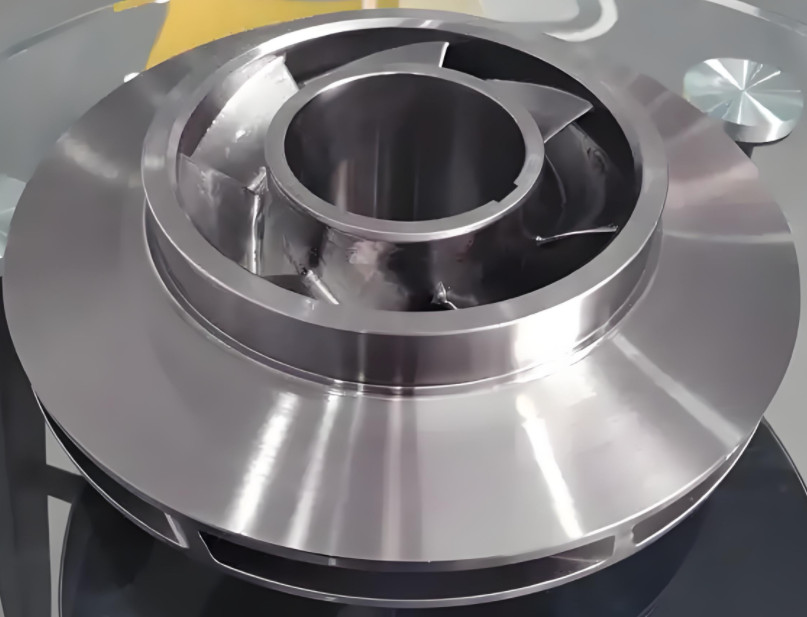

Micro scratches are fine, often invisible-to-the-naked-eye surface abrasions that occur during the polishing of vacuum pump aluminum alloy blades. These scratches, ranging from 0.1 to 10 micrometers in depth, can degrade the blade’s aerodynamic performance, increase wear, and lead to particle contamination in vacuum systems. Aluminum alloys, commonly used in vacuum pump blades due to their lightweight and corrosion-resistant properties, are particularly susceptible to micro scratches because of their relatively soft surface (Vickers hardness typically 50–150 HV).

The polishing process aims to achieve a surface roughness (Ra) of 0.05–0.2 micrometers, but improper techniques or equipment can introduce defects. Identifying the root causes of micro scratches requires a systematic analysis of the polishing environment, tools, and materials.

Causes of Micro Scratches During Polishing

Micro scratches result from multiple factors, including equipment, abrasives, operator technique, and environmental conditions. Below is a detailed breakdown of the primary causes.

Contaminated Polishing Media

Polishing compounds, such as aluminum oxide or diamond pastes, often contain particles of varying sizes. If the abrasive media is contaminated with larger particles (e.g., >5 micrometers), these can embed into the blade surface, creating scratches. For instance, a 1-micrometer diamond paste contaminated with 10-micrometer particles can cause visible linear marks under 50x magnification.

Additionally, debris from prior polishing steps, such as metal shavings or dust, can mix with the polishing media, exacerbating the issue. Poor filtration or inadequate cleaning of polishing pads compounds this problem.

Inadequate Surface Preparation

Before polishing, blades must undergo grinding or sanding to remove machining marks. If the initial surface is too rough (e.g., Ra > 1 micrometer), subsequent polishing may fail to eliminate deeper scratches, leaving micro scratches as remnants. For example, using 400-grit sandpaper followed directly by a 1-micrometer polishing compound skips critical intermediate steps, resulting in uneven surfaces.

Improper Polishing Equipment

Polishing tools, such as rotary buffers or orbital polishers, must operate at controlled speeds and pressures. Excessive speed (e.g., >3000 RPM for aluminum alloys) generates heat, softening the blade surface and increasing scratch susceptibility. Similarly, high pressure (>0.5 MPa) can embed abrasive particles into the aluminum, creating linear marks. Worn or low-quality polishing pads, such as those with uneven foam density, also contribute to inconsistent finishes.

Environmental Contamination

Dust, airborne particles, or residue in the polishing environment can settle on the blade or polishing pad, acting as unintended abrasives. In cleanroom settings (e.g., ISO Class 7), particle counts should not exceed 352,000 particles per cubic meter (≥0.5 micrometers), yet even minor lapses in environmental control can introduce defects.

Operator Technique

Inconsistent pressure, incorrect motion (e.g., random vs. linear strokes), or insufficient polishing time can lead to micro scratches. For instance, applying uneven force during hand polishing creates localized high-pressure zones, increasing the likelihood of abrasions. Lack of training or experience further amplifies these issues.

Solutions to Prevent and Remove Micro Scratches

Addressing micro scratches requires a combination of preventive measures and corrective techniques. The following solutions are designed to optimize the polishing process and ensure a smooth, defect-free surface.

Optimizing Polishing Media

Use high-purity polishing compounds with tightly controlled particle sizes. For aluminum alloy blades, start with a 3-micrometer diamond paste, progressing to 1-micrometer and 0.25-micrometer pastes for final polishing. Ensure compounds are free of contaminants by sourcing from reputable suppliers and storing in sealed containers.

Regularly clean polishing pads with deionized water and inspect for embedded debris. Replace pads after 50–100 cycles or when wear is visible. A filtration system for liquid polishing compounds can further reduce contamination risks.

Proper Surface Preparation

Follow a multi-step surface preparation process to achieve a uniform starting point. A recommended sequence is outlined in the table below:

| Step | Abrasive | Grit Size | Surface Roughness (Ra, μm) | Notes |

|---|---|---|---|---|

| Coarse Grinding | Silicon Carbide Paper | 240 | 0.8–1.2 | Remove machining marks |

| Intermediate Sanding | Silicon Carbide Paper | 600 | 0.4–0.6 | Smooth coarse scratches |

| Fine Sanding | Silicon Carbide Paper | 1200 | 0.1–0.2 | Prepare for polishing |

| Initial Polishing | Diamond Paste | 3 μm | 0.05–0.1 | Begin surface refinement |

Each step should be followed by thorough cleaning with isopropyl alcohol to remove residual abrasives.

Selecting Appropriate Polishing Equipment

Use dual-action or orbital polishers with adjustable speeds (1000–2000 RPM) to minimize heat buildup. Apply a maximum pressure of 0.2–0.3 MPa to avoid embedding abrasives. High-density foam pads (e.g., 80–100 PPI) are ideal for aluminum alloys, as they provide consistent contact without excessive aggression.

Regularly calibrate equipment to ensure stable performance. For automated systems, program polishing paths to maintain uniform motion, avoiding localized over-polishing.

Maintaining a Clean Polishing Environment

Conduct polishing in a controlled environment, ideally an ISO Class 6 cleanroom with particle counts below 35,200 per cubic meter (≥0.5 micrometers). Use HEPA-filtered air systems and antistatic measures to reduce dust accumulation. Cover blades when not in use, and clean work surfaces with lint-free wipes before each session.

Improving Operator Technique

Train operators in systematic polishing techniques, emphasizing consistent pressure (0.1–0.2 MPa) and linear or crosshatch motion patterns. For hand polishing, use microfiber applicators to reduce friction. Implement quality checks using 50x–100x optical microscopes to detect micro scratches early.

Establish standard operating procedures (SOPs) for each polishing stage, including time per step (e.g., 5–10 minutes per square centimeter for final polishing) and inspection protocols.

Corrective Measures for Existing Micro Scratches

If micro scratches are detected, corrective polishing can restore the surface. Follow these steps:

- Assess Scratch Depth: Use a profilometer to measure scratch depth. Scratches <1 micrometer can be polished directly; deeper scratches require sanding.

- Sand Lightly: For scratches >1 micrometer, use 2000-grit silicon carbide paper with water lubrication to minimize heat.

- Polish Progressively: Apply 1-micrometer diamond paste with a soft foam pad, followed by 0.25-micrometer paste for a mirror finish.

- Inspect and Clean: Verify surface quality under 100x magnification and clean with isopropyl alcohol.

Quality Control and Validation

Implement rigorous quality control to ensure scratch-free surfaces. Use surface roughness testers to measure Ra values, targeting 0.05–0.1 micrometers. Conduct periodic audits of polishing media, equipment, and environmental conditions. Document all processes in a quality management system to track performance and identify recurring issues.

Validation testing, such as accelerated wear tests or particle generation analysis, can confirm the effectiveness of the polished blades in vacuum pump applications.

Conclusion

Micro scratches during vacuum pump aluminum alloy blade polishing stem from contaminated media, inadequate preparation, improper equipment, environmental factors, and operator errors. By optimizing polishing compounds, following a structured preparation sequence, using suitable equipment, maintaining a clean environment, and enhancing operator skills, these defects can be minimized. Corrective measures and robust quality control further ensure a high-quality finish, improving blade performance and longevity. This systematic approach provides a reliable framework for achieving defect-free surfaces in demanding vacuum pump applications.