Ceramics machining is a specialized process used to shape and finish ceramic materials into precise components for industries such as aerospace, electronics, and medical devices. Ceramics, known for their hardness, thermal stability, and chemical resistance, are challenging to machine due to their brittle nature and high hardness. This guide provides a detailed overview of ceramics machining, including types of techniques, specific parameters, and associated difficulties, offering a systematic approach for professionals seeking to understand and implement effective machining strategies.

Understanding Ceramics and Their Properties

Ceramics are inorganic, non-metallic materials typically composed of metallic and non-metallic elements bonded through ionic or covalent bonds. Common ceramics include alumina (Al₂O₃), zirconia (ZrO₂), silicon carbide (SiC), and silicon nitride (Si₃N₄). These materials are valued for their high hardness (often exceeding 9 on the Mohs scale), thermal stability (up to 1600°C for some ceramics), and resistance to corrosion and wear. However, these properties also make ceramics prone to cracking and chipping during machining, necessitating specialized techniques and tools.

The machinability of ceramics varies by type. For instance, alumina is widely used for its balance of hardness and cost, while zirconia offers superior fracture toughness, making it ideal for dental implants. Silicon carbide excels in high-temperature applications, such as aerospace components, but its extreme hardness requires diamond tools for machining. Understanding these properties is critical for selecting appropriate machining methods and parameters.

Types of Ceramics Machining Techniques

Ceramics machining employs both conventional and non-conventional techniques, each suited to specific materials and applications. Below is a detailed examination of the primary methods used in ceramics machining, along with their applications and technical considerations.

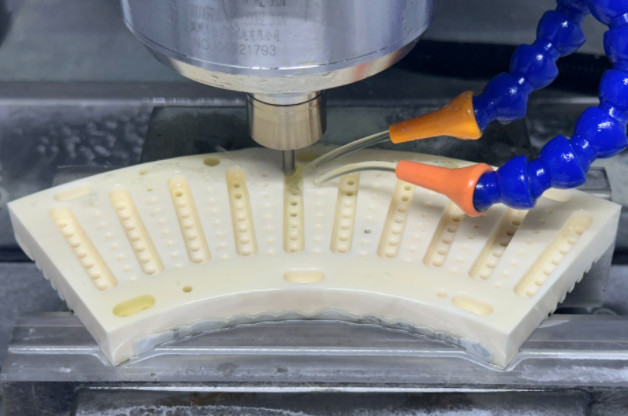

Grinding

Grinding is the most common conventional method for machining ceramics, using abrasive wheels or belts to remove material and achieve precise shapes and surface finishes. It is suitable for both roughing and finishing operations and can handle a wide range of ceramics, including alumina, zirconia, and silicon carbide. Grinding wheels, often diamond-coated, are selected based on grit size (e.g., 80–120 for roughing, 400–600 for finishing) and bond type (resin or vitrified for ceramics).

Parameters:

- Wheel Speed: 20–35 m/s for diamond wheels to balance material removal and tool wear.

- Feed Rate: 0.01–0.05 mm/pass to minimize cracking.

- Depth of Cut: 0.02–0.1 mm for finishing, up to 0.5 mm for roughing.

- Coolant: Water-based coolant to reduce thermal stress.

Grinding offers excellent control over dimensional tolerances (down to ±0.005 mm) but requires careful parameter selection to avoid surface damage or excessive tool wear.

Turning

Turning involves rotating the ceramic workpiece while a single-point cutting tool removes material to create cylindrical or conical shapes. It is commonly used for components like tubes or shafts in electronics and aerospace. Diamond-tipped or carbide tools are preferred due to their wear resistance. Turning ceramics requires high spindle speeds and low feed rates to prevent chipping.

Parameters:

- Spindle Speed: 1000–3000 rpm for zirconia, 500–1500 rpm for silicon carbide.

- Feed Rate: 0.02–0.1 mm/rev to ensure surface integrity.

- Depth of Cut: 0.05–0.2 mm to avoid excessive stress.

- Coolant: Synthetic coolant or compressed air for heat dissipation.

Turning is effective for simple geometries but less suitable for intricate designs due to the risk of tool wear and material fracture.

Drilling

Drilling creates holes in ceramic components for applications like electrical connections or mounting hardware. Specialized diamond or carbide drills are used, often with ultrasonic assistance to reduce cutting forces. Drilling parameters must be tightly controlled to prevent cracking, especially in brittle ceramics like alumina.

Parameters:

- Drill Speed: 500–2000 rpm, depending on ceramic hardness.

- Feed Rate: 0.01–0.05 mm/rev to minimize chipping.

- Coolant: High-pressure coolant to reduce heat buildup.

- Drill Geometry: Point angle of 118–135° for optimal penetration.

Drilling is critical for precision applications but requires robust tools and precise control to achieve accurate hole dimensions.

Electrical Discharge Machining (EDM)

EDM is a non-contact method that uses electrical sparks to erode material, suitable for conductive ceramics like silicon-infiltrated silicon carbide. It is ideal for creating complex shapes or fine holes that are difficult to achieve with mechanical methods. EDM is limited to ceramics with electrical resistivity below 100 Ω-cm.

Parameters:

- Pulse Duration: 10–100 µs for controlled material removal.

- Current: 5–20 A, adjusted for material conductivity.

- Dielectric Fluid: Oil or deionized water to stabilize sparking.

EDM offers high precision but may introduce surface microcracks, requiring post-machining inspection.

Laser Machining

Laser machining uses high-energy laser beams (e.g., CO₂ or Nd:YAG) to remove material through vaporization or ablation. It is effective for cutting intricate geometries in ceramics like mullite or quartz. Laser machining is non-contact, reducing mechanical stress, but thermal effects must be managed.

Parameters:

- Laser Power: 100–500 W for cutting, 50–200 W for engraving.

- Scan Speed: 100–1000 mm/s to control heat-affected zones.

- Pulse Frequency: 10–50 kHz for precise material removal.

Laser machining is versatile but requires careful calibration to avoid thermal cracking.

Ultrasonic Machining

Ultrasonic machining uses high-frequency vibrations (20–40 kHz) combined with abrasive slurry to remove material. It is suitable for brittle ceramics like glass or alumina and is effective for complex shapes. The process is slow but minimizes mechanical damage.

Parameters:

- Vibration Frequency: 20–30 kHz for optimal abrasion.

- Abrasive Grit Size: 100–400 mesh for different surface finishes.

- Feed Rate: 0.01–0.1 mm/min to ensure precision.

Ultrasonic machining is ideal for delicate components but has lower material removal rates compared to grinding.

Key Machining Parameters for Ceramics

Effective ceramics machining requires precise control of parameters to balance material removal rate, surface quality, and tool life. The following table summarizes typical parameters for common ceramics machining techniques.

| Technique瞎Technique | Material | Spindle/Wheel Speed | Feed Rate | Depth of Cut | Coolant |

|---|---|---|---|---|---|

| Grinding | Alumina, Zirconia, SiC | 20–35 m/s | 0.01–0.05 mm/pass | 0.02–0.5 mm | Water-based |

| Turning | Zirconia, Si₃N₄ | 1000–3000 rpm | 0.02–0.1 mm/rev | 0.05–0.2 mm | Synthetic/Compressed Air |

| Drilling | Alumina, Quartz | 500–2000 rpm | 0.01–0.05 mm/rev | N/A | High-pressure |

| Laser Machining | Mullite, Quartz | 100–500 W (power) | 100–1000 mm/s | N/A | N/A |

| Ultrasonic | Glass, Alumina | 20–30 kHz | 0.01–0.1 mm/min | N/A | Abrasive Slurry |

Difficulties in Ceramics Machining

Ceramics machining presents several difficulties due to the material’s inherent properties. These challenges require careful consideration of tools, parameters, and techniques to achieve high-quality results.

High Hardness and Tool Wear

The extreme hardness of ceramics (e.g., Vickers hardness of 15–20 GPa for alumina) causes rapid wear on conventional tools. Diamond-coated or carbide tools are necessary, but even these experience significant wear, increasing costs and affecting dimensional accuracy. For example, machining silicon carbide with polycrystalline diamond (PCD) tools can extend tool life by 10–20% compared to carbide tools, but frequent tool replacement is still required.

Brittleness and Cracking

Ceramics are brittle, with low fracture toughness (e.g., 3–5 MPa·m¹/² for alumina). This makes them prone to cracking and chipping during machining, particularly under high cutting forces. Low feed rates and shallow depths of cut are essential to minimize stress concentrations. For instance, a feed rate of 0.01–0.05 mm/rev is recommended for drilling to reduce the risk of microcracks.

Thermal Management

Ceramics have low thermal conductivity (e.g., 2–30 W/m·K), leading to heat buildup during machining. This can cause thermal cracking or dimensional inaccuracies. Effective cooling, such as high-pressure coolant systems or water-based coolants, is critical to dissipate heat and maintain material integrity.

Surface Finish Challenges

Achieving smooth surface finishes (e.g., Ra < 0.4 µm) is difficult due to ceramics’ brittleness, which can lead to microcracks and surface roughness. Post-machining processes like lapping or polishing are often required to meet stringent surface quality requirements, particularly for applications in electronics and medical devices.

Best Practices for Effective Ceramics Machining

To address the difficulties of ceramics machining, the following best practices are recommended:

- Use Specialized Tools: Employ diamond-coated or carbide tools designed for ceramics to reduce wear and improve precision.

- Optimize Parameters: Select appropriate spindle speeds, feed rates, and depths of cut based on the ceramic type and machining method.

- Implement Cooling: Use water-based coolants or compressed air to manage heat buildup and prevent thermal damage.

- Control Vibrations: Ensure machine stability and use vibration-damping techniques to minimize workpiece damage.

- Perform Quality Control: Conduct post-machining inspections to detect microcracks, surface defects, or dimensional inaccuracies.

By adhering to these practices, manufacturers can achieve high-precision ceramic components while minimizing defects and costs.

Applications of Machined Ceramic Components

Machined ceramic components are used across various industries due to their unique properties. In aerospace, silicon carbide components are used in turbine blades due to their high-temperature resistance. In electronics, alumina substrates provide excellent electrical insulation for circuit boards. In medical applications, zirconia is used for dental implants and prostheses due to its biocompatibility and corrosion resistance. The precision achieved through ceramics machining ensures these components meet stringent performance requirements.

Conclusion

Ceramics machining is a complex but essential process for producing high-precision components for demanding applications. By understanding the properties of ceramics, selecting appropriate machining techniques, and optimizing parameters, manufacturers can overcome challenges such as tool wear, brittleness, and thermal issues. Grinding, turning, drilling, EDM, laser machining, and ultrasonic machining each offer unique advantages, and careful parameter control is critical to achieving desired outcomes. This guide provides a comprehensive framework for professionals to navigate the intricacies of ceramics machining, ensuring high-quality results in industrial applications.