The calculation of CNC machining costs is quite complex because it depends on many factors.

All machined parts must be customized according to drawings. Therefore, compared with other

manufacturing methods, CNC machining cost estimation is more complicated. In other words,

there is no fixed standard formula for estimating the cost of machined parts.

Tip 1: Choose Appropriate Raw Materials and Consider Machinability

The selection of raw materials affects costs in two ways: the cost of the material itself and

the machining time. Machinability refers to how easily the material can be cut or processed

to achieve a satisfactory surface finish at a lower cost. The higher the machinability, the

faster the CNC machining speed, thereby reducing costs.

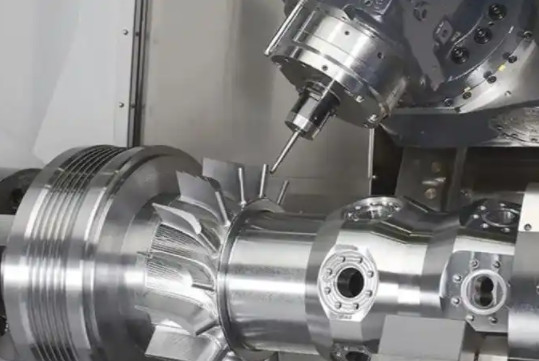

Tip 2: Find Suitable and Efficient Machining Equipment

There are many types of CNC machines available. Using advanced and expensive equipment for

simple parts does not make us the best supplier—it depends on the design of the part. We

should use appropriate equipment to manufacture your parts at a reasonable price. The right

equipment is the best!

The hourly cost of different CNC machines varies according to their capabilities and

efficiency. For example, if a part can be turned on both an automatic lathe and a CNC lathe

while meeting tolerance requirements, the automatic lathe will generally be more cost-effective.

Tip 3: Allow Radii Instead of 90° Corners

CNC milling cutters are cylindrical and produce radii at cavity edges. Achieving a 90° corner

requires extra time and special tools, which increases machining time and cost. If 90° angles

are not functionally necessary, allow radii at internal vertical edges and external vertical slots.

Tip 4: Specify Tolerances Only When Necessary

Manufacturers need tolerances specified in technical drawings. Without tolerances, they will

follow general standards like ISO 2768, which are sufficient for most non-critical features.

For functional or assembly-critical dimensions, specify tolerances as required.

Cost-saving tip: Only specify tolerances when necessary and avoid overusing tight tolerances.

Tip 5: Minimize Deep Cavity Depth

CNC machining is a subtractive process that removes material to achieve the required shape.

Deep cavities require more material removal, increasing machining time and cost. Reduce cavity

depth whenever possible.

Tip 6: Avoid Thin-Wall Designs

Thin walls often occur when holes or threads are close to edges. Thin walls require special

processes, slower machining speeds, and custom fixtures to ensure accuracy. Even then, parts

may deform or be scrapped, increasing costs.

Thicker walls are more stable and cost-effective. Design metal parts with wall thickness ≥0.8 mm,

and plastic parts with wall thickness ≥1.5 mm whenever possible.

Tip 7: Use Standard Hole Sizes and Threads

Standard holes and threads can be quickly machined with standard drills and taps while achieving

good precision. Non-standard sizes require custom tools, increasing costs.

Cost-saving tip: Design holes with standard diameters. For diameters ≤10 mm, use 0.1 mm increments.

For diameters >10 mm, use 0.5 mm increments.

Tip 8: Avoid Multiple Surface Finishes Whenever Possible

Surface finishes improve appearance and prevent corrosion, but they also increase costs,

especially when multiple finishes are applied, particularly locally.

Cost-saving tips:

- Use as-machined surfaces if they meet functional requirements.

- Only apply multiple finishes when absolutely necessary.

Tip 9: Choose Laser Engraving Instead of CNC Engraving

For text or logos, laser engraving is faster and more cost-effective. CNC engraving removes

more material, taking longer and costing more.

Tip 10: Order in Bulk Whenever Possible

For large orders, machine shops can purchase raw materials in bulk at better prices without

worrying about supplier minimum order quantities. Continuous CNC production of the same part

maximizes efficiency and reduces costs.