Have You Encountered These Frustrating Situations: Parts won’t fit, wear out in just a few days, or customers complain about substandard surfaces—actually, 90% of these problems are related to part surface roughness!

Surface roughness directly determines a part’s friction coefficient, service life, assembly accuracy, and even impacts your procurement costs.

What is Surface Roughness?

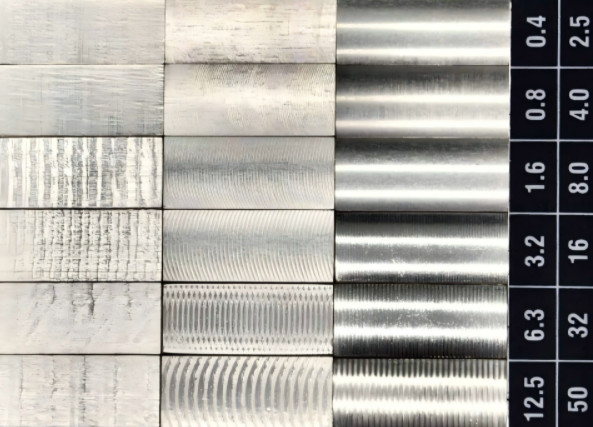

The surface roughness of a part after CNC machining is a measurement of the average texture of the part's surface. There are different parameters for defining surface roughness, with the common one being Ra (Arithmetical Mean Deviation of the Profile), which is calculated based on the differences in surface height and depth, and is measured in micrometers (μm) under a microscope. Surface roughness is distinct from the concept of surface finish: although precision machining techniques can improve the surface finish of machined parts, surface roughness specifically refers to the surface texture of a part after machining.

How to Achieve Different Surface Roughness Levels?

The surface roughness of a part after machining is not random; instead, it is controlled to meet specific standards, meaning this value is preset but cannot be arbitrarily specified. There are widely accepted Ra standards in the manufacturing industry, such as those specified in ISO 4287. In CNC machining, Ra values can be clearly specified, ranging from 25 μm to 0.025 μm to meet different requirements.

We offer four surface roughness grades, which are also typical values for CNC machining applications:

- 3.2 μm Ra

- 1.6 μm Ra

- 0.8 μm Ra

- 0.4 μm Ra

Different machining processes have different requirements for surface roughness. A lower roughness value is only specified when there are specific needs, because achieving a lower Ra value requires more machining processes and stricter quality control, which increases costs and lead times. Therefore, when a specific roughness is required, post-processing operations are usually not performed first—since post-processing is difficult to control precisely and may affect the dimensional tolerance of the part.

In some machining scenarios, surface roughness affects the function, performance, and durability of the part, and is directly related to factors such as friction coefficient, noise, wear, heat generation, and adhesion. The importance of these factors varies by application; thus, surface roughness may be unimportant in some cases but extremely critical in others. For example, it is crucial for components used in high-tension, high-stress, or high-vibration environments; components requiring precise fitting and smooth movement; high-speed rotating parts; and medical implants. Different conditions demand different surface roughness levels.

The following sections will explain these roughness grades and all the information you need to select the appropriate Ra value for your application.

3.2 μm Ra

This is a commonly used surface treatment parameter. It is suitable for most parts, as it is sufficiently smooth while still having visible machining marks. Unless otherwise specified, this surface roughness is used by default.

3.2 μm Ra is the recommended maximum surface roughness value for parts subjected to stress, loads, and vibration. It can also be used for mating surfaces in moving components when the load is light and the movement speed is slow. To achieve this roughness, machining requires high speed, fine feed rate, and light cutting.

1.6 μm Ra

Typically, only slight cutting marks are visible when this option is used. This Ra value is suitable for tight-fitting parts, load-bearing parts, and slow-moving, light-load surfaces—but not for high-speed rotating or high-vibration components. This surface roughness is achieved through machining under controlled conditions with high speed, fine feed rate, and light cutting.

Cost: For standard aluminum alloys (e.g., 3.1645), this option increases the production cost by approximately 2.5%. The cost will further increase as the complexity of the part rises.

0.8 μm Ra

This high-grade surface finish requires strict control during production and incurs higher costs. It is used for parts with stress concentration. It can also be used for bearings when the bearings move occasionally and are under light loads.

Cost: For standard aluminum alloys (e.g., 3.1645), this option increases the production cost by approximately 5%. The cost will further increase as the complexity of the part rises.

0.4 μm Ra

This finer ("less rough") surface roughness represents a high-quality surface treatment. It is suitable for parts subjected to high tension or stress; it is also required for high-speed rotating components such as bearings and shafts. Due to the complex manufacturing processes involved, this roughness grade is only selected when smoothness is critical.

Cost: For standard aluminum alloys (e.g., 3.1645), this option increases the production cost by approximately 11–15%. The cost will further increase as the complexity of the part rises.

What Impacts Does Surface Roughness Have?

1. Part Performance: Determines Whether It Works and How Long It Lasts

Invisible tiny unevenness (such as a rough trace of 0.1μm, which is only 1/500 the thickness of a human hair) directly affects the friction, heat generation, and adhesion of parts. For example:

- If a seal has an excessively rough surface, it will leak fluid;

- If an optical part is not smooth enough, it will affect light transmittance;

- If the surface of a moving component fails to meet standards, it will wear out and be scrapped in just 3 months.

2. Cost Control: Smoother Is Not Necessarily Cheaper!

Is a smoother surface always better? No—achieving a smoother surface requires longer processing time and more precise equipment, which can increase costs by 2 to 3 times. For example:

- For hidden bracket parts, a surface roughness of 3.2μm Ra is sufficient to meet requirements; there’s no need to spend extra money to achieve 0.8μm Ra;

- For parts that need gluing, intentionally leaving a slight roughness (e.g., 6.3μm Ra) can actually make the glue adhere more firmly while reducing processing costs.

3. Delivery Schedule Guarantee: Choosing the Right Roughness for Complex Parts Avoids Rework Delays

If a part has a complex structure such as deep cavities or thin walls, forcing extremely low roughness may lead to tool breakage or deformation during processing. One or two reworks can delay the delivery schedule by more than 10 days.

CNC Surface Roughness Grade Correspondence Table

| Roughness Grade (Ra) | Surface Effect | Recommended Application Scenarios | Processing Cost | Impact on Delivery |

|---|---|---|---|---|

| 0.1–0.4μm | Mirror-like smooth | Optical parts, precision seals, cylinder rods | High (2–3x more expensive) | Long (requires multiple polishing) |

| 0.8–1.6μm | Very smooth | Bearings, gears, precision fitting parts | Medium | Medium |

| 3.2μm | Generally smooth | Brackets, housings, non-fitting structural parts | Low | Short (conventional processing) |

| 6.3–12.5μm | Slightly rough | Welded parts, glued parts, hidden connectors | Very low | Shortest |

Take an example: When purchasing a batch of equipment housings, choosing 3.2μm Ra not only ensures the appearance but also reduces costs by 30% compared to 1.6μm Ra, while advancing the delivery schedule by 3 days!

How to Choose the Right CNC Machining Surface Roughness

Choosing the appropriate CNC machining surface roughness is crucial for ensuring performance, cost-effectiveness, and suitability for the target application. To make the right choice, you must carefully evaluate several factors, including the component’s function, material properties, and design complexity.

Function and Purpose

Consider the specific function of the CNC-machined part, as surface roughness directly affects performance. For components such as cylinder rods and optical parts, a smooth surface is essential (e.g., 0.4μm Ra).

Cost and Delivery Time

A smoother surface requires longer processing time and increases production costs. For non-critical components, a surface roughness of 3.2μm Ra can save time and reduce expenses.

Material Properties

The achievable surface roughness depends on the material. For example, aluminum can reach an Ra value between 0.1μm and 1μm, while materials like steel may have a higher (less smooth) limit.

Part Geometry

Complex designs with intricate geometries require more time and advanced equipment to achieve a lower Ra value. For projects with tight budgets and deadlines, consider using a rougher surface finish to balance cost and feasibility.