CNC machining and laser machining are two prominent manufacturing processes used across industries to create precise components. Both methods offer unique advantages and limitations, making them suitable for different applications. This article provides a detailed comparison of CNC machining and laser machining, focusing on their processes, material compatibility, precision, speed, costs, and applications. The goal is to offer a clear, technical understanding to help manufacturers and engineers choose the appropriate method for their needs.

Overview of CNC Machining

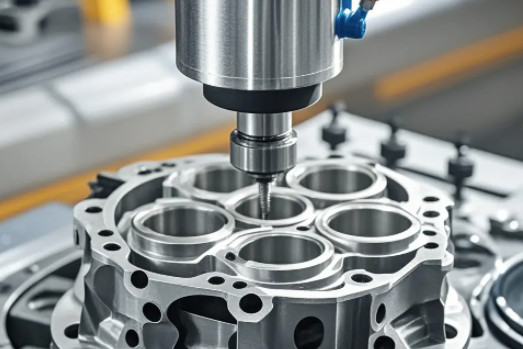

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece to create a desired shape. The process involves pre-programmed software that dictates the movement of tools and machinery, such as mills, lathes, or routers. CNC machines operate on multiple axes (typically 3 to 5 axes), allowing for complex geometries and high precision.

The CNC machining process begins with a digital design, often created using CAD (Computer-Aided Design) software. This design is converted into G-code, which instructs the machine on tool paths, speeds, and feeds. The workpiece is secured on the machine, and tools like drills, end mills, or turning tools remove material layer by layer. CNC machining is widely used in industries such as aerospace, automotive, and medical device manufacturing due to its versatility and accuracy.

Key Parameters:

- Tool Materials: High-speed steel (HSS), carbide, or diamond-coated tools.

- Spindle Speed: 1,000–50,000 RPM, depending on material and tool.

- Feed Rate: 0.1–100 inches per minute (IPM), based on material hardness.

- Tolerance: ±0.001 inches (0.025 mm) for standard setups, tighter with advanced machines.

Overview of Laser Machining

Laser machining is a non-contact, thermal-based process that uses a focused laser beam to remove material from a workpiece. The laser beam, guided by CNC or G-code, melts, burns, or vaporizes the material, often assisted by a jet of gas to clear debris. Laser machining includes processes like laser cutting, engraving, drilling, and ablation, each suited for specific applications.

The process relies on high-power lasers, such as CO2, Nd:YAG, or fiber lasers, which are directed through optics to achieve precision. Laser machining is commonly used in industries like electronics, jewelry, and sheet metal fabrication due to its ability to produce clean cuts and intricate patterns without physical contact. The absence of tool wear makes it ideal for repetitive tasks.

Key Parameters:

- Laser Power: 500–6,000 watts for cutting, lower for engraving.

- Beam Diameter: 0.1–0.3 mm for focused beams.

- Cutting Speed: 0.5–10 meters per minute, depending on material thickness.

- Tolerance: ±0.001 inches (0.025 mm) for thin materials, slightly wider for thicker ones.

Process Comparison

CNC machining and laser machining differ fundamentally in their material removal mechanisms. CNC machining is a mechanical process involving physical contact between tools and the workpiece, while laser machining is a thermal process with no physical contact. This distinction affects their suitability for various materials, geometries, and production volumes.

| Aspect | CNC Machining | Laser Machining |

|---|---|---|

| Material Removal | Mechanical (cutting, drilling, milling) | Thermal (melting, vaporizing) |

| Contact | Physical contact with tools | Non-contact |

| Tool Wear | Tools wear over time, requiring replacement | No tool wear, only optics maintenance |

| Setup Complexity | Requires fixturing and tool changes | Minimal fixturing, simpler setup |

CNC machining excels in creating 3D parts with complex internal features, such as pockets or threads, due to its multi-axis capabilities. Laser machining, however, is better suited for 2D profiles or thin materials, as its thermal nature limits its ability to produce deep features without affecting surrounding areas.

Material Compatibility

Both processes handle a wide range of materials, but their compatibility varies based on material properties like hardness, thermal conductivity, and reflectivity.

CNC Machining: CNC machines can process nearly any material, including metals (aluminum, steel, titanium), plastics (ABS, nylon, PEEK), composites, and wood. The choice of tools and parameters allows for tailored machining of soft or hard materials. For example, carbide tools are used for stainless steel, while diamond-coated tools handle composites. However, very brittle materials like ceramics may crack under mechanical stress.

Laser Machining: Laser machining is effective for metals (stainless steel, aluminum, copper), non-metals (plastics, wood, glass), and brittle materials like ceramics. CO2 lasers are ideal for non-metals, while fiber lasers excel with reflective metals. Highly reflective materials (e.g., pure copper) or thick materials (>25 mm steel) pose challenges, as they require higher power or multiple passes, increasing costs.

Considerations: CNC machining is more versatile for thick or dense materials, while laser machining is preferred for thin sheets or materials sensitive to mechanical stress. For instance, laser cutting achieves clean edges on 1–6 mm acrylic, whereas CNC milling may leave tool marks on similar materials.

Precision and Surface Finish

Both CNC machining and laser machining offer high precision, but their surface finish quality and tolerance capabilities differ due to their processes.

CNC Machining: CNC machines achieve tolerances as tight as ±0.001 inches (0.025 mm) with advanced setups reaching ±0.0005 inches (0.0127 mm). Surface finish ranges from 32–250 microinches (0.8–6.3 µm Ra), depending on tool selection and post-processing (e.g., polishing). The mechanical process can leave minor tool marks or burrs, which may require secondary finishing for aesthetic or functional parts.

Laser Machining: Laser machining also delivers tolerances of ±0.001 inches (0.025 mm) for thin materials, but tolerances may widen to ±0.004 inches (0.1 mm) for thicker materials due to heat-affected zones (HAZ). Surface finish is typically 125–250 microinches (3.125–6.25 µm Ra), smoother than CNC for most materials due to the non-contact process. However, HAZ can cause discoloration or micro-cracks in metals, necessitating post-processing in critical applications.

Comparison: CNC machining is ideal for parts requiring ultra-tight tolerances and complex 3D features, while laser machining produces smoother edges on thin materials with slightly less precision for thicker ones.

Speed and Production Efficiency

Production speed depends on material, part complexity, and volume. CNC machining is generally slower due to its layer-by-layer material removal, while laser machining is faster for specific tasks like cutting thin sheets.

CNC Machining: Speed is determined by feed rates (0.1–100 IPM) and spindle speeds (1,000–50,000 RPM). Complex parts with multiple setups or deep cuts take longer, often requiring hours for a single piece. High-volume production benefits from automated tool changers but remains slower than laser for simple profiles. For example, machining a 10 mm aluminum block into a bracket may take 30–60 minutes.

Laser Machining: Laser cutting speeds range from 0.5–10 meters per minute, making it faster for 2D profiles. A 3 mm steel sheet can be cut at 5–7 m/min with a 4 kW fiber laser. However, thicker materials or intricate patterns reduce speed, and multiple passes may be needed. Engraving or drilling is slower than cutting, often taking seconds to minutes per feature.

Comparison: Laser machining is faster for thin materials and simple geometries, while CNC machining is better for complex, thick parts despite longer processing times.

Cost Analysis

Costs for CNC machining and laser machining depend on equipment, labor, material, and production volume. Both processes have high initial investments but differ in operational expenses.

CNC Machining: CNC machines cost $50,000–$500,000, with 5-axis models at the higher end. Tooling costs add $10–$100 per tool, and frequent replacements increase expenses for hard materials. Labor costs are higher due to skilled operators and setup time. Per-part costs are $10–$500, higher for complex or low-volume parts. Economies of scale improve with automation for high volumes.

Laser Machining: Laser machines range from $100,000–$1,000,000, with fiber lasers being pricier. Maintenance includes optics and gas (e.g., nitrogen at $0.5–$2 per hour). Labor costs are lower due to simpler setups and less operator intervention. Per-part costs are $1–$100, lower for thin materials and high volumes. Thick materials increase costs due to slower speeds and higher power needs.

| Cost Factor | CNC Machining | Laser Machining |

|---|---|---|

| Equipment | $50,000–$500,000 | $100,000–$1,000,000 |

| Tooling/Maintenance | $10–$100 per tool | Optics and gas ($0.5–$2/hour) |

| Per-Part Cost | $10–$500 | $1–$100 |

Applications and Suitability

CNC Machining: Ideal for parts requiring complex 3D geometries, tight tolerances, or thick materials. Common applications include aerospace components (turbine blades, turbine rotor, turbine impeller), automotive parts (engine blocks), and medical implants. It suits low-to-medium volumes due to setup costs but can scale with automation.

Laser Machining: Best for 2D profiles, thin materials, or intricate patterns. Applications include sheet metal fabrication (enclosures), electronics (circuit boards), and jewelry (engravings). It excels in high-volume production of simple shapes due to speed and low per-part costs.

Choosing the Right Process: Select CNC machining for parts with internal features, thick materials, or diverse material types. Choose laser machining for thin sheets, clean edges, or non-contact processing of brittle materials.

Conclusion

CNC machining and laser machining are complementary processes with distinct strengths. CNC machining offers versatility for complex, thick parts, while laser machining provides speed and precision for thin materials and 2D profiles. By understanding their processes, material compatibility, precision, speed, costs, and applications, manufacturers can make informed decisions to optimize production efficiency and quality.