CNC metal machining is a cornerstone of modern manufacturing, delivering high-precision components for industries such as aerospace, automotive, medical, and electronics. This process uses computer numerical control (CNC) systems to automate machinery, ensuring accuracy, repeatability, and efficiency in shaping metal parts. This article explores the key aspects of CNC metal machining, including processes, materials, applications, and technical considerations, providing a comprehensive guide for professionals and businesses seeking reliable manufacturing solutions.

What is CNC Metal Machining?

CNC metal machining involves the use of computer-controlled tools to remove material from a metal workpiece, creating parts with precise dimensions and complex geometries. Unlike manual machining, CNC systems rely on pre-programmed software to dictate tool movements, ensuring consistent results. This technology is widely used for producing prototypes, custom parts, and high-volume production runs. The process encompasses various techniques, each suited to specific manufacturing needs.

Key CNC Machining Processes for Metals

Several CNC machining processes are employed for metal fabrication, each offering unique capabilities. Below are the primary methods used in CNC metal machining:

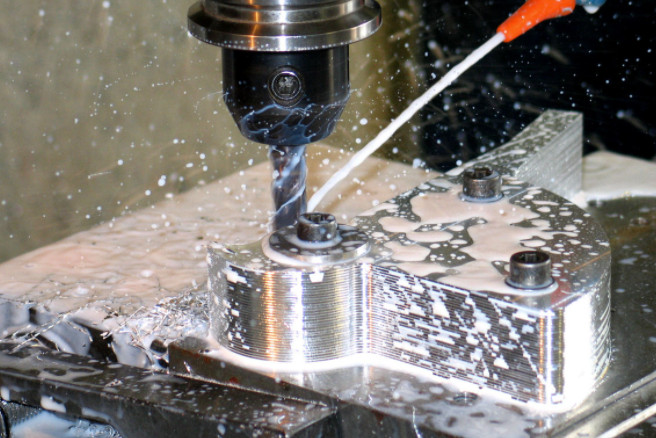

CNC Milling

CNC milling uses rotating cutting tools to remove material from a stationary workpiece. The process is versatile, capable of producing slots, holes, contours, and flat surfaces. Key parameters include:

- Spindle Speed: Typically ranges from 1,000 to 20,000 RPM, depending on the material and tool.

- Feed Rate: Varies between 0.1 to 100 inches per minute, adjusted for metal hardness.

- Tool Types: End mills, face mills, and ball mills for different surface finishes.

CNC milling is ideal for creating complex 3D shapes and is widely used in aerospace for components like turbine blades.

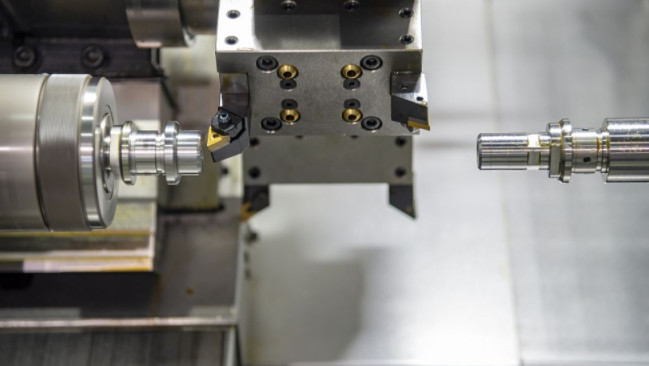

CNC Turning

CNC turning involves rotating the workpiece while a stationary cutting tool shapes it. This process is suited for cylindrical parts like shafts and bolts. Key parameters include:

- Rotational Speed: 500 to 5,000 RPM, depending on material diameter and type.

- Cutting Depth: Typically 0.01 to 0.25 inches per pass for precision.

- Tool Materials: Carbide or high-speed steel for durability.

Turning is efficient for high-volume production and delivers excellent surface finishes.

CNC Drilling

CNC drilling creates precise holes in metal workpieces using rotating drill bits. It is used for mounting holes, fastener placements, and fluid passages. Parameters include:

- Drill Bit Diameter: Ranges from 0.1 to 2 inches for standard applications.

- Feed Rate: 0.002 to 0.02 inches per revolution, depending on metal type.

- Coolant Use: Essential for reducing heat and extending tool life.

Drilling is critical in industries like automotive for engine block manufacturing.

CNC Grinding

CNC grinding uses abrasive wheels to achieve ultra-smooth surfaces and tight tolerances. It is often used for finishing processes. Parameters include:

- Wheel Speed: 5,000 to 12,000 surface feet per minute.

- Workpiece Speed: Adjusted to prevent thermal damage.

- Grinding Wheel Types: Aluminum oxide or diamond for different metals.

Grinding is essential for tools and dies requiring high precision.

Materials Used in CNC Metal Machining

CNC machining supports a wide range of metals, each chosen based on application requirements. The following table summarizes common materials and their properties:

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, high machinability | Aerospace parts, automotive frames |

| Stainless Steel | High strength, corrosion-resistant | Medical devices, marine components |

| Titanium | High strength-to-weight ratio, biocompatible | Aerospace fasteners, medical implants |

| Brass | Good machinability, aesthetic finish | Decorative parts, electrical connectors |

| Tool Steel | High hardness, wear-resistant | Cutting tools, molds |

Material selection depends on factors like strength, weight, corrosion resistance, and cost, tailored to the specific application.

Applications of CNC Metal Machining

CNC metal machining serves diverse industries, producing components that meet stringent performance standards. Key applications include:

- Aerospace: Precision parts like turbine blades, landing gear components, and structural fittings, requiring tolerances as tight as ±0.0005 inches.

- Automotive: Engine parts, transmission components, and suspension systems, manufactured for durability and precision.

- Medical: Surgical instruments, implants, and diagnostic equipment, often made from biocompatible materials like titanium.

- Electronics: Heat sinks, enclosures, and connectors, requiring intricate designs and high conductivity.

- Energy: Components for turbines, valves, and pipelines, designed for high-pressure and high-temperature environments.

Each application demands specific machining processes and material properties to ensure functionality and reliability.

Technical Considerations in CNC Metal Machining

Successful CNC metal machining requires careful attention to several technical factors to achieve desired outcomes. These include:

Tool Selection

Choosing the right cutting tools is critical for efficiency and quality. Tools must match the material’s hardness and the desired finish. For example, carbide tools are preferred for hard metals like titanium, while high-speed steel suits softer materials like aluminum.

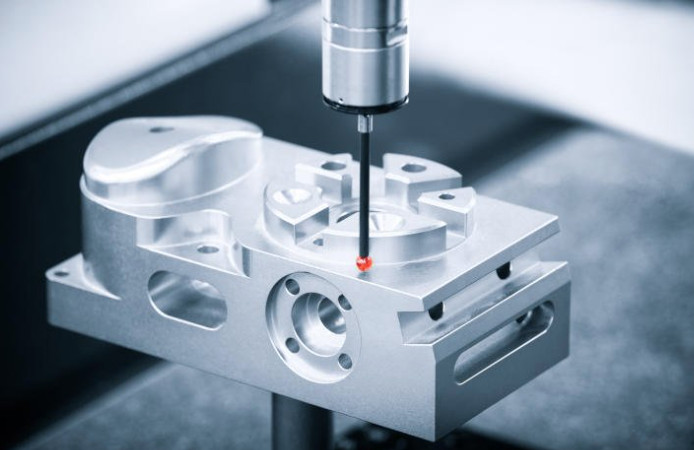

Tolerances and Precision

CNC machining can achieve tolerances as tight as ±0.0001 inches for critical applications. However, tighter tolerances increase machining time and costs, requiring a balance between precision and efficiency.

Surface Finish

Surface finish affects both aesthetics and functionality. Common measurements include Ra (roughness average), with values ranging from 0.8 to 3.2 micrometers for most applications. Grinding and polishing can achieve smoother finishes when required.

Coolant and Lubrication

Coolants reduce heat and friction, extending tool life and preventing workpiece distortion. Common coolants include water-based emulsions and synthetic fluids, applied at rates of 5 to 50 gallons per minute, depending on the process.

Machine Calibration

Regular calibration ensures CNC machines maintain accuracy. Calibration intervals depend on usage but are typically performed every 6 to 12 months, using laser interferometry for precision checks.

Advantages of CNC Metal Machining

CNC metal machining offers several benefits that make it a preferred manufacturing method:

- Precision: Achieves tight tolerances for complex geometries.

- Repeatability: Ensures consistent quality across large production runs.

- Versatility: Supports a wide range of metals and machining processes.

- Efficiency: Automation reduces labor costs and production time.

- Customization: Ideal for prototypes and bespoke components.

These advantages make CNC machining indispensable for industries requiring high-quality metal parts.

Common CNC Machining Equipment

CNC machining relies on advanced equipment tailored to specific tasks. The following table outlines common machines and their capabilities:

| Machine Type | Capabilities | Typical Applications |

|---|---|---|

| CNC Lathe | Turning, threading, facing | Shafts, bolts, cylindrical parts |

| CNC Mill | Milling, drilling, slotting | Complex 3D shapes, flat surfaces |

| CNC Grinder | Surface finishing, precision grinding | Tools, dies, bearings |

| CNC Drill | Hole making, tapping | Engine blocks, mounting plates |

Each machine type is equipped with multi-axis capabilities (3 to 5 axes) to handle complex geometries.

Conclusion

CNC metal machining is a highly precise and versatile manufacturing process that delivers critical components for industries worldwide. By leveraging advanced processes like milling, turning, drilling, and grinding, manufacturers can produce parts with exceptional accuracy and durability. Understanding the materials, equipment, and technical considerations ensures optimal results for any project. Whether for aerospace, automotive, or medical applications, CNC metal machining remains a vital solution for high-quality production.

FAQ About CNC Metal Machining

What metals can be used in CNC machining?

Common metals include aluminum, stainless steel, titanium, brass, and tool steel, chosen based on strength, machinability, and application needs.

What is the typical tolerance for CNC metal machining?

Tolerances typically range from ±0.001 to ±0.0001 inches, depending on the application and machine capabilities.

How long does CNC metal machining take?

Lead times vary based on part complexity, material, and volume, typically ranging from hours for simple parts to weeks for complex production runs.