CNC milling is a cornerstone of modern manufacturing, enabling the production of complex parts with high precision and repeatability. This guide provides a detailed overview of CNC milling for complex parts, including machine components, design considerations, material selection, and advanced techniques. Whether you're an engineer, manufacturer, or CNC operator, this resource equips you with the knowledge to optimize your milling processes.

Understanding CNC Milling and Complex Parts

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled rotating cutting tools to remove material from a workpiece, creating precise shapes and features. Complex parts are characterized by intricate geometries, tight tolerances, thin walls, deep cavities, or non-standard features that require advanced machining strategies. These parts are critical in industries like aerospace, automotive, medical, and electronics, where precision and reliability are paramount.

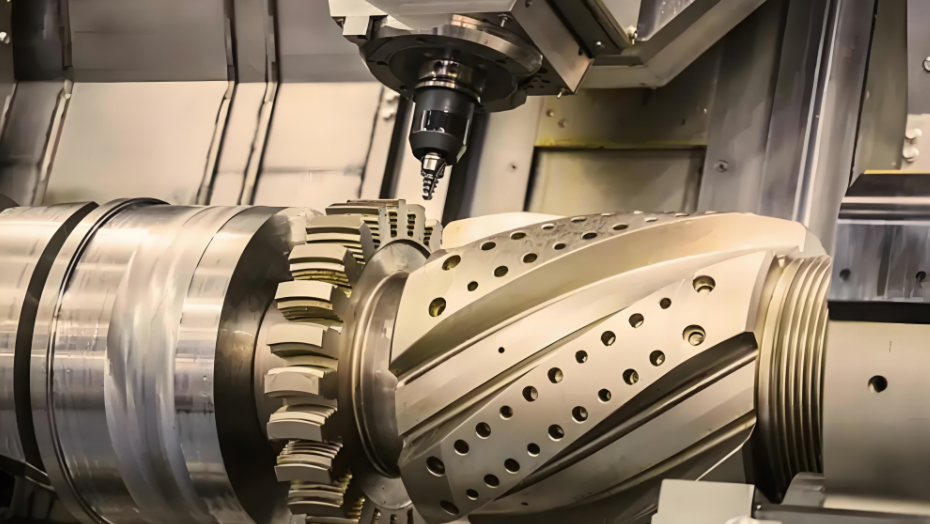

The ability to machine complex parts depends on several factors, including the machine’s capabilities, tool selection, workholding, and programming. Multi-axis CNC machines, such as 4-axis or 5-axis systems, are often used to achieve the flexibility needed for intricate designs. Understanding the components and processes involved is essential for optimizing outcomes.

Key Components of a CNC Milling Machine

A CNC milling machine comprises several critical components that work together to achieve precision and efficiency. Each part plays a specific role in ensuring the machine can handle complex geometries. Below is a table summarizing the major components and their functions.

| Component | Function | Key Specifications |

|---|---|---|

| Machine Control Unit (MCU) | Interprets G-code, coordinates movements, and controls operations | Supports G-code/M-code, real-time feedback, high-resolution processing |

| Spindle | Rotates cutting tools at high speeds | 10,000–30,000 RPM, 5–50 kW power, taper standards (e.g., CAT40, HSK) |

| Worktable | Holds and positions the workpiece | Movable in X, Y, Z axes, T-slot or vacuum table designs |

| Tool Changer | Automatically swaps tools for multi-operation tasks | 8–30 tool capacity, 2–5 seconds change time |

| Servo Motors | Drive axis movements with precision | 0.1 µm positioning accuracy, 1–5 kW power |

| Coolant System | Reduces heat and friction during machining | 10–50 L/min flow rate, water- or oil-based coolants |

The MCU acts as the brain, translating G-code into precise movements. The spindle, powered by a motor, rotates tools at speeds tailored to the material and operation. The worktable, supported by the saddle and knee, moves along multiple axes to position the workpiece accurately. Servo motors ensure smooth and precise motion, while the coolant system maintains tool and workpiece integrity. For complex parts, an automatic tool changer (ATC) enhances efficiency by reducing downtime during tool switches.

Design Considerations for Complex Parts

Designing parts for CNC milling requires careful planning to ensure manufacturability, cost-efficiency, and precision. Below are key considerations for optimizing complex part designs.

Tool Geometry and Access

CNC cutting tools, such as end mills and drills, have a cylindrical shape with limited cutting lengths (typically 3–4 times the tool diameter). To accommodate this, design cavities with a depth-to-width ratio of up to 4:1 for standard tools. For deeper cavities (up to 30:1), specialized tools are required, with a maximum depth of 35 cm for a 1-inch diameter end mill. Ensure internal corner radii are at least 1/3 of the cavity depth to allow tool access.

Tolerances and Surface Finish

Tight tolerances (e.g., ±0.005 mm) are achievable but increase machining time and cost. Standard tolerances (±0.025 mm) are sufficient for most applications. Surface finishes, measured in Ra (roughness average), typically range from 0.8 µm (smooth) to 3.2 µm (standard). Specify finishes based on functional requirements, as smoother finishes require additional passes, increasing costs.

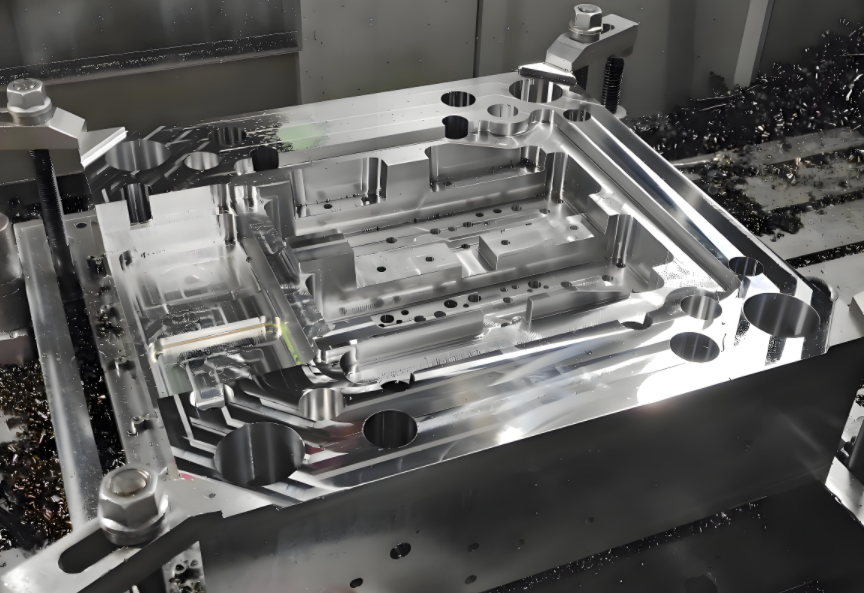

Workholding and Setup

Secure workholding is critical for complex parts to prevent vibration or movement. Vacuum tables or custom fixtures are ideal for multi-axis machining, reducing setup changes. For 5-axis machines, a single setup can machine multiple sides, minimizing errors. Plan the order of operations to maintain rigidity until the final cut, especially for thin-walled parts.

Material Selection

Material choice impacts machinability, tool wear, and part performance. Common materials include aluminum (lightweight, corrosion-resistant), stainless steel (high strength, durable), and engineering plastics like PEEK or Delrin (low friction, chemical resistance). Select materials based on the part’s functional requirements and machining capabilities.

Advanced CNC Milling Techniques

Producing complex parts often requires advanced techniques to achieve high precision and efficiency. Below are the primary methods used in modern CNC milling.

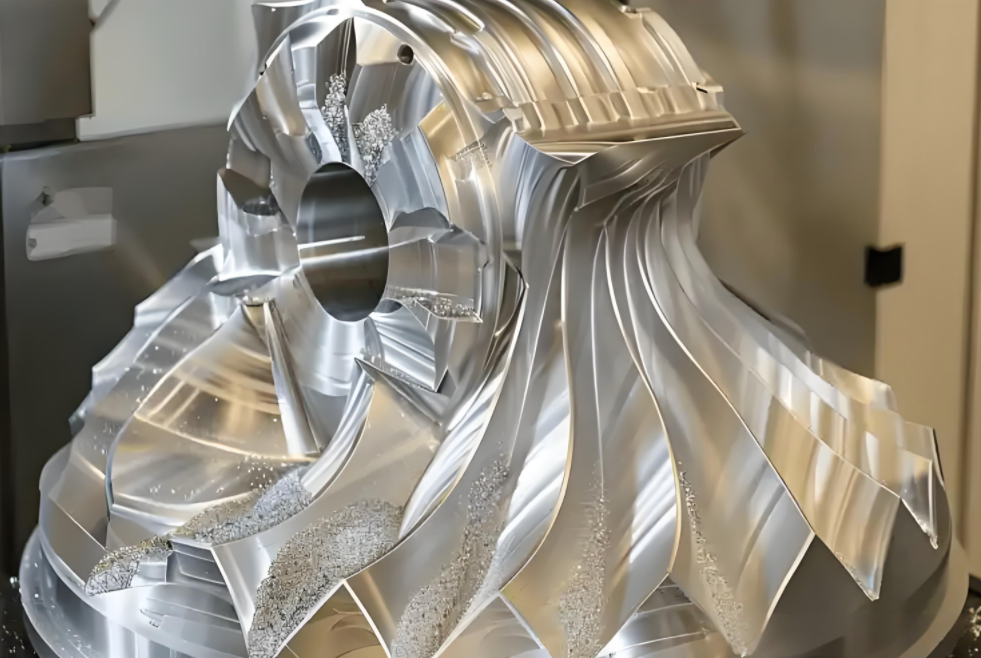

Multi-Axis Machining

Multi-axis machines (4-axis or 5-axis) allow simultaneous movement along multiple axes, enabling the machining of complex geometries in a single setup. For example, 5-axis machines can cut angles inaccessible to 3-axis machines, reducing setup time and improving accuracy. Typical applications include turbine blades, impellers, and medical implants.

High-Speed Machining

High-speed machining (HSM) uses high spindle speeds (20,000–50,000 RPM) and optimized feed rates to remove material quickly. This technique is ideal for aluminum and soft materials, reducing cycle times while maintaining precision. HSM requires robust machine rigidity and advanced toolpaths to prevent tool deflection.

Micro-Milling

Micro-milling employs tools with diameters as small as a few micrometers to create intricate features with tolerances as tight as ±0.002 mm. It is critical for electronics, optics, and medical devices, where sub-micron surface finishes (Ra < 0.4 µm) are required. Specialized machines and vibration control are essential for success.

Adaptive Machining

Adaptive machining uses real-time sensor feedback to adjust cutting parameters, such as feed rate and depth, based on material conditions. This technique improves tool life and consistency, especially for parts with variable geometries or hard materials like titanium.

Material Selection for CNC Milling

Choosing the right material is critical for balancing performance, cost, and machinability. The table below outlines common materials, their properties, and typical applications.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good machinability | Aerospace components, automotive parts, electronics housings |

| Stainless Steel | High strength, corrosion-resistant, moderate machinability | Medical implants, automotive gears, aerospace fittings |

| Titanium | High strength-to-weight ratio, biocompatible, challenging to machine | Aerospace fasteners, medical prosthetics |

| PEEK | Chemical-resistant, low friction, good machinability | Medical devices, aerospace insulators |

| Delrin (POM) | High stiffness, low friction, excellent machinability | Gears, bearings, consumer electronics |

Material selection should consider factors like strength, weight, corrosion resistance, and thermal stability. For complex parts, prioritize materials with good machinability to reduce tool wear and machining time, especially for high-volume production.

Best Practices for CNC Milling Complex Parts

To achieve optimal results when milling complex parts, follow these best practices:

- Optimize Toolpaths: Use CAM software to generate efficient toolpaths, minimizing unnecessary movements and reducing cycle times.

- Calibrate Regularly: Ensure machine calibration to maintain accuracy, especially for tight tolerances.

- Use Probing Technology: Employ probes to measure part surfaces and adjust toolpaths in real-time for enhanced precision.

- Select Appropriate Tools: Choose carbide or ceramic-coated tools for hard materials and high-speed applications to improve durability.

- Maintain Rigidity: Use robust workholding solutions, such as vacuum tables or custom fixtures, to prevent part movement during machining.

- Monitor Coolant Use: Apply appropriate coolant to manage heat and extend tool life, especially for deep cavities or hard materials.

Applications of CNC Milling for Complex Parts

CNC milling is widely used across industries to produce complex parts with high precision. Key applications include:

- Aerospace: Turbine blades, engine mounts, and structural components requiring tight tolerances and lightweight materials.

- Automotive: Engine blocks, transmission parts, and custom prototypes for performance vehicles.

- Medical: Surgical instruments, implants, and prosthetics made from biocompatible materials like titanium.

- Electronics: Heat sinks, connectors, and enclosures with intricate designs and fine tolerances.

These applications highlight the versatility of CNC milling in meeting diverse industry demands for precision and complexity.

Conclusion

CNC milling complex parts requires a deep understanding of machine components, design principles, material properties, and advanced techniques. By leveraging multi-axis machining, high-speed techniques, and robust workholding, manufacturers can achieve unparalleled precision and efficiency. Selecting the right materials and optimizing toolpaths further enhance outcomes, making CNC milling a vital tool for industries requiring intricate, high-quality components. With the right knowledge and strategies, you can unlock the full potential of CNC milling for your manufacturing needs.