Looking for a reliable partner for high-precision CNC milling services? At Kesu, we deliver advanced CNC milling solutions tailored for rapid prototyping, small-batch production, and high-volume manufacturing. Our ISO 9001:2015-certified facilities, cutting-edge CNC technology, and expert team ensure that your parts are produced with exceptional accuracy, quality, and speed. This comprehensive guide explores the CNC milling process, its benefits, materials, surface finishes, applications, and why Kesu is your ideal choice for custom CNC milling services.

What is CNC Milling?

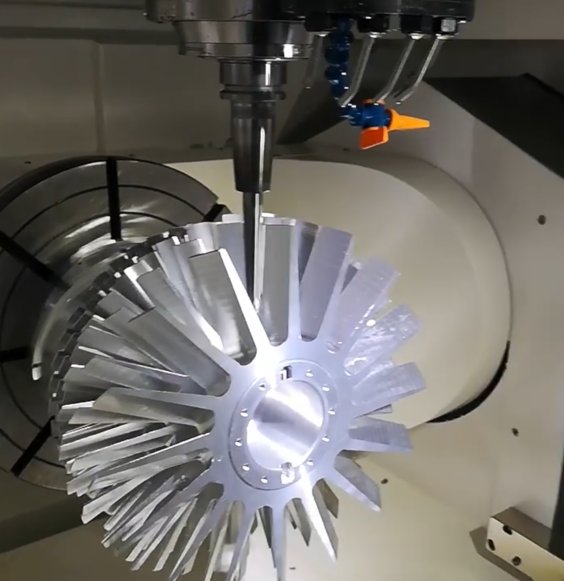

CNC milling is a subtractive manufacturing process that uses computer numerical control (CNC) to remove material from a workpiece, creating complex parts with high precision. Unlike CNC turning, which is suited for cylindrical parts, CNC milling excels at producing intricate geometries, including cavities, slots, holes, and contoured surfaces. Our CNC milling services support a wide range of industries, from aerospace to electronics, delivering parts that meet the most stringent specifications.

The CNC Milling Process

The CNC milling process involves several steps to transform raw material into a finished part. Below is an overview of the process:

- CAD Design: A computer-aided design (CAD) model is created using software like SolidWorks, Fusion 360, or AutoCAD to define the part’s geometry.

- CAM Programming: The CAD model is imported into computer-aided manufacturing (CAM) software, which generates G-code to control the CNC milling machine’s movements.

- Workpiece Setup: The raw material (e.g., a metal or plastic block) is secured on the machine’s worktable using clamps, vises, or fixtures.

- Machining: The CNC milling machine rotates a cutting tool at speeds ranging from 2,000 to 20,000 RPM, moving along multiple axes (X, Y, Z, and sometimes A or B) to remove material and shape the part.

- Finishing: Post-machining processes, such as deburring, polishing, or surface treatment, are applied to achieve the desired finish.

- Quality Inspection: Parts are inspected using tools like coordinate measuring machines (CMM) and surface profilometers to ensure tolerances as tight as ±0.005 mm.

Key Parameters in CNC Milling

Precision CNC milling requires careful control of several parameters to achieve optimal results. These include:

- Spindle Speed: Ranges from 2,000 to 20,000 RPM, depending on the material, tool type, and part complexity.

- Feed Rate: Typically between 0.01 to 0.3 mm/tooth, balancing material removal rate and surface finish quality.

- Cutting Depth: Varies from 0.05 to 10 mm per pass, optimized to prevent tool wear and ensure accuracy.

- Tool Types: Includes end mills, face mills, ball mills, and drills, with diameters ranging from 0.5 to 50 mm.

- Tolerances: Achieves tolerances as tight as ±0.005 mm for high-precision parts.

- Surface Roughness: Produces finishes with Ra values as low as 0.2 µm for polished surfaces.

- Axes of Motion: Supports 3-, 4-, and 5-axis milling, with 5-axis machines offering rotational angles up to ±120° for complex geometries.

Benefits of Kesu’s CNC Milling Services

Kesu’s CNC milling services combine advanced technology, skilled expertise, and a customer-focused approach to deliver superior results. Below are the key advantages:

Unmatched Precision and Quality

Our CNC milling services produce parts with exceptional precision, achieving tolerances as tight as ±0.005 mm. Our ISO 9001:2015-certified facilities employ advanced inspection tools, including CMM, laser scanners, and surface profilometers, to ensure every part meets rigorous quality standards. We follow strict Design for Manufacturability (DFM) principles to optimize designs and minimize errors.

Versatile Material Options

We offer a wide range of materials to suit diverse applications, including:

- Metals: Aluminium (6061, 7075), stainless steel (304, 316, 17-4 PH), steel (1018, 4140), brass (C360), copper (C101), titanium (Grade 2, Grade 5), and special alloys (Inconel 625, Monel K500).

- Plastics: POM (Delrin), PTFE (Teflon), PEEK, PC (polycarbonate), PMMA (acrylic), ABS, PPS, and PA (nylon).

- Material Properties: For example, stainless steel 316 offers a yield strength of 205 MPa and corrosion resistance, while PEEK provides thermal stability up to 250°C.

Diverse Surface Finishes

We provide a variety of surface treatments to enhance the functionality, durability, and aesthetics of CNC-milled parts. Options include:

- As-Machined: Delivers a uniform finish with Ra values of 0.8–1.6 µm, suitable for functional components.

- Sandblasting: Creates a matte finish using grit sizes from 120 to 320, ideal for visual appeal.

- Anodizing: Type II (5–25 µm thickness) for decorative and corrosion-resistant finishes, and Type III (25–50 µm) for hard, wear-resistant coatings, available in colors like black, red, and clear.

- Powder Coating: Applies a durable layer (50–150 µm thick) in various colors, offering superior abrasion resistance compared to paint.

- Electroplating: Adds a metal coating (e.g., nickel, chrome) with thicknesses of 5–50 µm for enhanced conductivity or wear resistance.

Cost-Effective Production

Our CNC milling services are optimized for cost efficiency. By leveraging high-speed 5-axis CNC machines with cycle times as low as 20 seconds per feature, we reduce machining time and material waste. Our DFM expertise ensures designs are streamlined for manufacturing, lowering startup and production costs. We also offer competitive pricing and will match or beat quotes from other providers.

Rapid Turnaround and Global Delivery

Located in China’s Greater Bay Area, we offer lead times as short as 3–5 days for prototypes and 7–14 days for production runs. Proximity to major shipping ports enables fast delivery, with transit times to North America and Europe typically ranging from 5 to 10 days. Our logistics team ensures seamless communication and timely delivery worldwide.

Custom CNC Milling Solutions

We specialize in custom CNC milling for complex geometries, hard-to-machine materials, and unique requirements. Whether you need to replace obsolete parts, machine high-performance alloys like Inconel, or produce intricate components with tight tolerances, our team provides end-to-end support, from design consultation to quality assurance.

Applications of CNC Milling

CNC milling is a versatile process used to create parts with complex geometries across multiple industries. Below are some common applications and their specific requirements:

Automotive Industry

CNC milling is critical for producing high-precision automotive components that enhance performance and reliability. Examples include:

- Engine Blocks: Require tolerances of ±0.01 mm and surface finishes of Ra 0.8 µm for optimal sealing and performance.

- Transmission Housings: Made from aluminium 6061 (tensile strength 310 MPa) for lightweight durability.

- Brake Calipers: Demand complex geometries and high-strength materials like stainless steel 17-4 PH (yield strength 1,100 MPa).

Aerospace Industry

Aerospace applications require lightweight, high-strength parts that meet stringent safety standards. CNC milling is used for:

- Structural Brackets: Made from titanium Grade 5 (yield strength 880 MPa) with tolerances of ±0.005 mm.

- Turbine Blades: Require 5-axis milling for complex contours and high-temperature resistance (up to 600°C).

- Avionics Housings: Produced from aluminium 7075 (tensile strength 570 MPa) with anodized finishes for corrosion resistance.

Medical Industry

CNC milling produces precision components for medical devices, where biocompatibility and accuracy are paramount. Examples include:

- Surgical Tools: Made from stainless steel 316L with surface finishes of Ra 0.4 µm for hygiene and precision.

- Orthopedic Implants: Titanium parts with tolerances of ±0.005 mm for perfect fit and biocompatibility.

- Diagnostic Equipment Housings: PEEK components with thermal stability up to 250°C and chemical resistance.

Electronics Industry

CNC milling supports the production of components for electronics, focusing on precision and thermal management. Applications include:

- Heat Sinks: Aluminium 6061 parts with thermal conductivity of 167 W/m·K and complex fin structures.

- Connector Housings: Brass or copper components with tolerances of ±0.01 mm and conductivity up to 59 MS/m.

- Enclosures: Anodized aluminium parts with Type III finishes for durability and EMI shielding.

Why Choose Kesu for CNC Milling Services?

Kesu’s CNC milling services offer a unique combination of precision, versatility, and efficiency. Here’s why we’re the preferred choice for global clients:

- Advanced Facilities: Our ISO 9001:2015-certified machine shop features 3-, 4-, and 5-axis CNC milling centers, capable of handling parts up to 2 meters in length.

- Expert Team: Our engineers, machinists, and quality specialists collaborate to deliver flawless parts, leveraging decades of experience.

- Comprehensive Solutions: We complement CNC milling with turning, EDM, 3D printing, and injection molding for end-to-end manufacturing.

- Competitive Pricing: Upload your CAD files for instant quotes, and we’ll match or beat competitors’ prices to win your business.

- Global Reach: Our strategic location in the Greater Bay Area ensures fast delivery and seamless communication with clients worldwide.

From prototypes to high-volume production, Kesu’s CNC milling services provide the quality, speed, and reliability you need to succeed.

Frequently Asked Questions (FAQ)

What is CNC milling?

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece, creating complex parts with high precision.

What materials can be used in CNC milling?

We offer a wide range of materials, including metals (aluminium, stainless steel, titanium, brass) and plastics (POM, PEEK, PTFE, ABS), as well as special alloys like Inconel.

What tolerances can CNC milling achieve?

CNC milling can achieve tolerances as tight as ±0.005 mm, making it ideal for high-precision applications in industries like aerospace and medical.

What surface finishes are available?

We provide as-machined, sandblasted, anodized (Type II and III), powder-coated, and electroplated finishes, with surface roughness as low as Ra 0.2 µm.

How fast is your turnaround time?

Prototypes can be delivered in 3–5 days, while production runs typically take 7–14 days, with expedited options available.

Do you offer custom CNC milling services?

Yes, we provide bespoke CNC milling for complex geometries, hard-to-machine materials, and unique requirements, with full design and quality support.