Stainless steel impellers are critical components in industries such as aerospace, marine, and chemical processing, requiring precise surface treatments to meet functional and aesthetic demands. Two common surface finishing methods—polishing and sandblasting—are widely used to enhance impeller performance and durability. This article provides a detailed comparison of their efficiency, focusing on process parameters, surface outcomes, and practical applications. The analysis is grounded in technical data and practical considerations to guide manufacturers in selecting the appropriate method for their needs.

Overview of Polishing and Sandblasting Processes

Polishing and sandblasting are distinct surface treatment techniques with unique mechanisms and outcomes. Understanding their processes is essential for evaluating their efficiency in treating stainless steel impellers.

Polishing Process

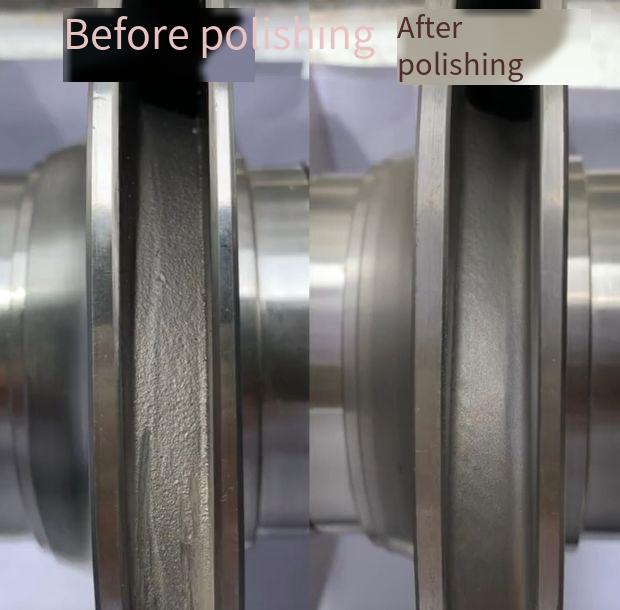

Polishing involves mechanically or chemically smoothing the surface of stainless steel to achieve a glossy, reflective finish. For impellers, mechanical polishing is typically employed, using abrasive tools such as polishing wheels, belts, or compounds. The process is divided into stages: rough grinding, medium grinding, and fine grinding. Each stage uses progressively finer abrasives to reduce surface roughness, with final roughness values often reaching Ra 0.2–0.4 µm. Polishing enhances aesthetic appeal, reduces surface irregularities, and improves corrosion resistance by minimizing crevices where contaminants can accumulate.

Key parameters include:

- Abrasive Grit Size: Ranges from 60–120 for rough grinding to 400–800 for fine polishing.

- Polishing Speed: Typically 1,500–3,000 RPM for rotary tools.

- Pressure: Controlled at 0.1–0.5 MPa to avoid surface damage.

- Time: 30–60 minutes per impeller, depending on size and complexity.

Polishing is labor-intensive and requires skilled operators to achieve uniform results, especially on complex geometries like impeller blades.

Sandblasting Process

Sandblasting, also known as abrasive blasting, propels abrasive particles at high velocity onto the stainless steel surface using compressed air or water. This creates a matte, textured finish with roughness values typically between Ra 1.0–2.0 µm. Sandblasting is effective for cleaning surfaces, removing oxides, and preparing impellers for coatings. Common abrasives include aluminum oxide, glass beads, and silicon carbide, selected based on the desired finish and material properties.

Key parameters include:

- Abrasive Type: Aluminum oxide (Mohs hardness 9) or glass beads (Mohs hardness 5–6).

- Pressure: 40–100 PSI, with lower pressures (40–60 PSI) for delicate surfaces.

- Nozzle Distance: 15–30 cm from the surface to control abrasion intensity.

- Time: 10–20 minutes per impeller, depending on surface area.

Sandblasting is faster and less labor-intensive than polishing but requires careful control to avoid over-etching or embedding abrasive particles.

Efficiency Metrics for Comparison

Efficiency in surface treatment is evaluated based on processing time, material consumption, labor requirements, and surface quality. Below, we compare polishing and sandblasting across these metrics for stainless steel impellers.

Processing Time

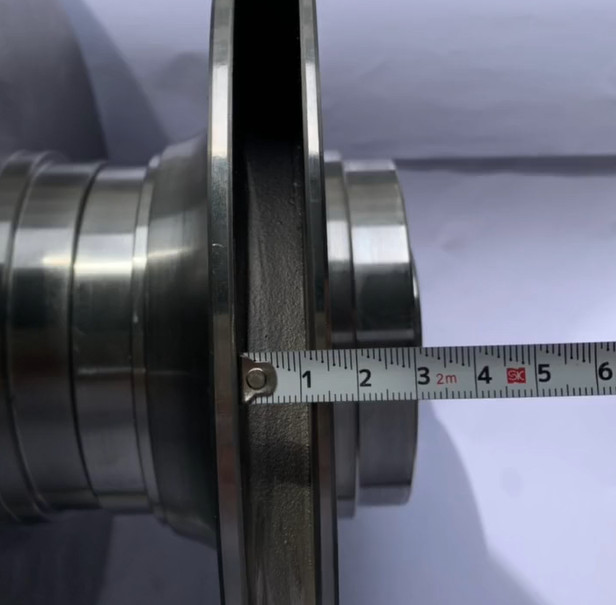

Polishing is a multi-stage process requiring sequential grinding and finishing, making it time-consuming. A typical impeller with a diameter of 300 mm may take 30–60 minutes to polish to a mirror finish (Ra < 0.4 µm). Automated polishing systems can reduce this to 20–40 minutes but are costly and less flexible for complex geometries.

Sandblasting, by contrast, is significantly faster. A similar impeller can be treated in 10–20 minutes, as the process involves a single pass with adjustable pressure and abrasive flow. Automated sandblasting systems further enhance speed, achieving up to 40% faster processing compared to manual polishing.

Material Consumption

Polishing consumes abrasive materials like polishing compounds, belts, and wheels, which require frequent replacement. For a single impeller, approximately 0.5–1 kg of polishing compound and 2–3 abrasive discs may be used, depending on the stages involved. Material costs are relatively low, but frequent tool replacement increases expenses over time.

Sandblasting uses abrasive media such as aluminum oxide or glass beads, with consumption rates of 5–7 kg per square meter of surface area. Recyclable abrasives like steel shot or garnet can reduce costs by 20–30%, as they can be reused multiple times. However, non-recyclable media like crushed glass increase material costs for large-scale operations.

Labor Requirements

Polishing demands skilled labor to ensure uniform finishes, particularly on curved impeller surfaces. Manual polishing requires operators to adjust pressure and angle continuously, increasing labor time and training costs. Automated polishing reduces labor needs but requires significant investment in equipment.

Sandblasting is less skill-intensive, as the process relies on equipment settings and consistent nozzle movement. Automated sandblasting systems, using robotic arms or conveyors, can reduce labor requirements by up to 50%, making it more suitable for high-volume production.

Surface Quality

Polishing produces a smooth, reflective surface with low roughness (Ra 0.2–0.4 µm), ideal for applications requiring high corrosion resistance and hygiene, such as impellers in food processing or medical equipment. However, achieving uniform results on complex impeller geometries can be challenging, and over-polishing may cause surface burning or dimensional inaccuracies.

Sandblasting creates a matte, textured surface (Ra 1.0–2.0 µm) that enhances coating adhesion but may increase susceptibility to corrosion in harsh environments if not properly treated post-blasting. The textured finish is less prone to fingerprints and scratches, making it suitable for impellers in industrial settings.

| Metric | Polishing | Sandblasting |

|---|---|---|

| Processing Time (per impeller) | 30–60 minutes | 10–20 minutes |

| Material Consumption | 0.5–1 kg compounds, 2–3 discs | 5–7 kg/m² abrasives |

| Labor Intensity | High (skilled operators) | Low (equipment-driven) |

| Surface Roughness (Ra) | 0.2–0.4 µm | 1.0–2.0 µm |

Applications and Suitability for Stainless Steel Impellers

The choice between polishing and sandblasting depends on the impeller’s intended application, environmental conditions, and performance requirements. Below, we explore their suitability in various contexts.

Polishing Applications

Polished stainless steel impellers are preferred in industries where hygiene and corrosion resistance are paramount. For example:

- Food and Beverage: Polished impellers (Ra < 0.4 µm) minimize bacterial adhesion and facilitate cleaning, meeting stringent sanitary standards.

- Medical Devices: Smooth surfaces reduce the risk of pitting corrosion in chloride-rich environments, critical for surgical equipment pumps.

- Aerospace: Polished impellers improve aerodynamic performance by reducing surface drag, enhancing efficiency in turbine systems.

Polishing is less effective for impellers requiring subsequent coatings, as the smooth surface provides poor adhesion compared to textured finishes.

Sandblasting Applications

Sandblasted impellers are suited for applications prioritizing durability and coating adhesion. Common uses include:

- Marine Industry: Sandblasting prepares impeller surfaces for anti-corrosive coatings, protecting against saltwater exposure.

- Chemical Processing: Textured surfaces enhance the adhesion of protective coatings, extending impeller lifespan in harsh chemical environments.

- Industrial Pumps: Sandblasted finishes reduce glare and resist scratches, maintaining appearance in high-wear settings.

Sandblasting is less suitable for applications requiring ultra-smooth surfaces, as the textured finish may increase friction or harbor contaminants if not properly sealed.

Practical Considerations for Implementation

Implementing polishing or sandblasting for stainless steel impellers involves several practical considerations to ensure efficiency and quality.

Equipment and Setup

Polishing requires specialized tools such as rotary polishers, abrasive belts, and compounds tailored to stainless steel grades (e.g., 304 or 316L). Equipment costs range from $5,000–$50,000 for automated systems, with maintenance costs for replacing worn tools. The setup must ensure consistent pressure and speed to avoid surface defects.

Sandblasting equipment includes air compressors, blasting pots, and nozzles, with costs ranging from $2,000–$20,000 for industrial setups. Proper ventilation and dust containment systems are critical to manage abrasive particles and ensure operator safety.

Material Selection

For polishing, non-ferrous abrasives like aluminum oxide or diamond compounds are preferred to avoid iron contamination, which can compromise corrosion resistance. For sandblasting, abrasives like glass beads (for smoother finishes) or aluminum oxide (for aggressive cleaning) are selected based on the desired roughness and impeller material.

Post-Treatment Requirements

Polished impellers typically require minimal post-treatment, as the smooth surface is ready for use or minor cleaning. Sandblasted impellers often need acid pickling or passivation to remove embedded particles and restore corrosion resistance, adding 5–10 minutes to the process time.

| Aspect | Polishing | Sandblasting |

|---|---|---|

| Equipment Cost | $5,000–$50,000 | $2,000–$20,000 |

| Abrasive Selection | Non-ferrous compounds | Glass beads, aluminum oxide |

| Post-Treatment | Minimal | Pickling/passivation |

Conclusion

Polishing and sandblasting offer distinct advantages for treating stainless steel impellers, with efficiency depending on the specific requirements of the application. Polishing excels in producing smooth, corrosion-resistant surfaces for hygiene-critical industries but is time-consuming and labor-intensive. Sandblasting is faster, more cost-effective, and ideal for coating preparation, though it requires post-treatment to maintain corrosion resistance. By understanding the process parameters, material consumption, and application suitability, manufacturers can make informed decisions to optimize impeller performance and durability.