Precision machining is a cornerstone of modern manufacturing, producing high-accuracy components for industries such as automotive, aerospace, and electronics. Understanding its cost structure is critical for manufacturers aiming to optimize production and maintain competitiveness. This analysis provides a detailed breakdown of the cost components in precision machining, focusing on direct and indirect costs, supported by a case study of BMW’s cost management practices. The discussion emphasizes practical, technical, and systematic insights to offer a clear and authoritative perspective.

Direct Costs in Precision Machining

Direct costs are expenses directly attributable to the production of machined components. These costs are traceable to specific products or processes and typically account for the largest share of total costs in precision machining. They include raw materials, labor, and manufacturing expenses.

Raw Materials

Raw materials represent the largest portion of direct costs, often constituting 40-60% of total production costs, depending on the material type and component complexity. Precision machining frequently involves high-grade materials such as stainless steel, titanium, aluminum alloys, or specialized polymers, which are selected for their strength, durability, or thermal properties. For example, titanium Grade 5 (Ti-6Al-4V), commonly used in aerospace, costs approximately $30–50 per kilogram, while high-strength stainless steel (e.g., 316L) ranges from $5–10 per kilogram. These materials require precise handling and processing, increasing costs due to waste minimization requirements and the need for advanced cutting tools, such as carbide or diamond-coated tools, which cost $50–200 per unit.

Material costs are influenced by factors such as market prices, supplier contracts, and batch sizes. For instance, bulk purchasing can reduce per-unit costs by 10-15%, but small-batch production, common in precision machining, limits such savings. Additionally, material waste, which can range from 5-20% depending on the machining process (e.g., CNC milling vs. turning), further impacts costs.

Labor Costs

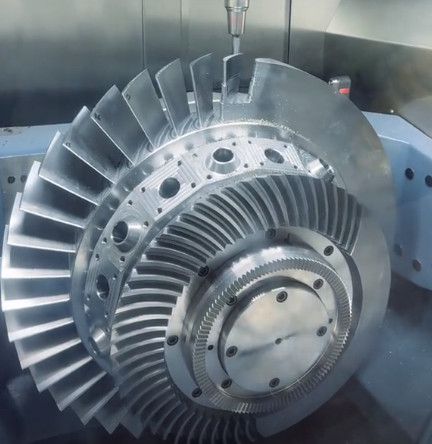

Labor costs in precision machining are significant due to the need for skilled technicians and engineers. Operators of CNC machines, for example, require expertise in programming, setup, and quality control, with average hourly wages ranging from $25–50 in industrialized regions like North America or Western Europe. A typical machining project may require 10–50 hours of labor per component, depending on complexity. For high-precision parts, such as turbine blades or medical implants, labor time can increase by 20-30% due to stringent quality checks and tolerances as tight as ±0.001 mm.

Labor costs also include training and certification. For instance, a CNC programmer may need 6–12 months of training, costing employers $10,000–20,000 per employee. Overtime, often required to meet tight deadlines, can increase labor costs by 1.5–2 times the standard rate.

Manufacturing Expenses

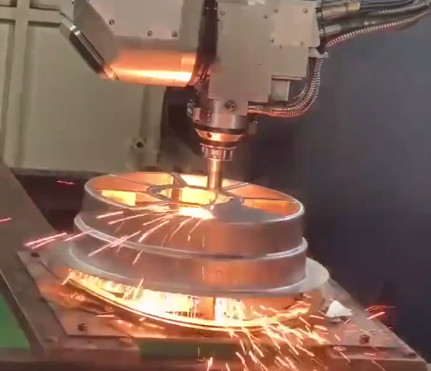

Manufacturing expenses encompass equipment maintenance, energy consumption, and logistics. Precision machining relies on advanced equipment like 5-axis CNC machines, which cost $100,000–500,000 per unit. Annual maintenance for such machines ranges from $5,000–15,000, depending on usage intensity. Energy costs are notable, with CNC machines consuming 5–20 kW per hour, leading to monthly electricity bills of $1,000–5,000 for a medium-sized facility operating 8 hours daily.

Logistics costs, including transportation of raw materials and finished parts, vary by region and distance. For example, shipping a 500 kg batch of components internationally may cost $500–2,000. Tooling costs, such as replacing worn cutting tools, add $1,000–5,000 monthly, depending on production volume and material hardness.

Indirect Costs in Precision Machining

Indirect costs are not directly tied to production but are essential for sustaining operations. These include management expenses, sales and marketing costs, and research and development (R&D) expenses. While indirect costs typically account for 20-30% of total costs, their impact on long-term efficiency and competitiveness is substantial.

Management Expenses

Management expenses cover salaries for administrative staff, facility overheads, and operational coordination. In precision machining, management teams oversee complex workflows, ensuring seamless integration of design, production, and quality control. For a mid-sized facility with 50 employees, annual management salaries range from $200,000–500,000, depending on the region and expertise level. Facility costs, including rent and utilities for a 10,000-square-foot plant, can range from $50,000–150,000 annually.

Effective management also involves implementing systems like Enterprise Resource Planning (ERP) software, which costs $10,000–50,000 annually for licensing and maintenance. These systems streamline inventory, scheduling, and cost tracking, reducing inefficiencies by 5-10%.

Sales and Marketing Costs

Sales and marketing costs support customer acquisition and brand visibility. In precision machining, these costs include trade show participation, digital marketing, and sales team salaries. Attending a major industry event, such as IMTS (International Manufacturing Technology Show), costs $10,000–50,000 per event, including booth setup and travel. Digital marketing, including website maintenance and SEO, ranges from $2,000–10,000 monthly for a competitive online presence. Sales staff, often earning $60,000–100,000 annually plus commissions, are critical for securing contracts in competitive markets like automotive or aerospace.

Research and Development Expenses

R&D expenses are incurred to develop new machining techniques, optimize processes, or design custom components. For example, developing a new machining process for a high-strength alloy may require 500–1,000 hours of engineering time, costing $50,000–100,000. Equipment for R&D, such as simulation software (e.g., ANSYS or Mastercam), costs $5,000–20,000 annually for licenses. While R&D is a smaller portion of indirect costs (typically 5-10%), it is critical for maintaining technological leadership in precision machining.

Case Study: BMW’s Cost Control in Precision Machining

BMW, a leading automotive manufacturer, exemplifies effective cost management in precision machining for components like engine parts and transmission systems. The company employs advanced CNC machining centers, such as those from DMG Mori, with spindle speeds up to 20,000 RPM and tolerances of ±0.005 mm. These machines, costing $200,000–400,000 each, enable high-efficiency production with minimal waste, reducing material costs by 10-15% compared to traditional methods.

BMW optimizes labor costs by investing in automated systems and employee training. For instance, its Leipzig plant uses robotic arms for material handling, reducing labor hours by 20% for certain components. Training programs ensure operators achieve certifications like ISO 9001, enhancing quality and reducing rework costs, which can account for 5-10% of production expenses in less optimized facilities.

Indirect costs are managed through streamlined supply chain operations and ERP systems. BMW’s global supplier network minimizes logistics costs by sourcing materials locally where possible, saving 5-8% on transportation. The company’s R&D investments, approximately 6% of annual revenue, focus on process optimization, such as reducing cycle times by 15% through advanced toolpath algorithms.

The following table summarizes BMW’s key cost control strategies:

| Cost Category | Strategy | Impact |

|---|---|---|

| Raw Materials | Advanced CNC machines, bulk purchasing | 10-15% cost reduction |

| Labor | Automation, employee training | 20% reduction in labor hours |

| Manufacturing Expenses | Optimized toolpaths, energy-efficient machines | 5-10% savings in energy and tooling |

| Indirect Costs | ERP systems, localized sourcing | 5-8% reduction in logistics costs |

Cost Structure Breakdown

The cost structure of precision machining varies by industry, scale, and region. The following table provides a typical cost distribution for a mid-sized precision machining operation producing automotive components:

| Cost Category | Percentage of Total Costs | Estimated Annual Cost (USD, 50-employee facility) |

|---|---|---|

| Raw Materials | 40-60% | $800,000–1,200,000 |

| Labor | 20-30% | $400,000–600,000 |

| Manufacturing Expenses | 10-15% | $200,000–300,000 |

| Indirect Costs | 20-30% | $400,000–600,000 |

This breakdown highlights the dominance of raw materials and the significant role of labor and indirect costs. Manufacturers can target specific areas, such as material waste reduction or automation, to achieve cost savings.

Precision Machining Excellence with Kesu

Kesu delivers unparalleled precision machining solutions, optimizing costs without compromising quality. Leveraging advanced CNC technology and rigorous cost control, we minimize raw material waste by up to 15% and reduce labor costs through automation, ensuring tolerances as tight as ±0.001 mm. Our streamlined management and localized sourcing cut indirect costs by 5-8%, providing reliable, high-efficiency manufacturing for industries like automotive and aerospace. Choose Kesu for technical expertise, cost-effective production, and trusted performance.

Conclusion

The cost structure of precision machining is complex, with direct costs (raw materials, labor, and manufacturing expenses) and indirect costs (managementទ5management, sales, and R&D) forming the backbone of operational expenses. Effective cost control, as demonstrated by BMW, involves optimizing material usage, automating processes, and streamlining management systems. By understanding and managing these cost components, manufacturers can enhance efficiency and competitiveness in the precision machining industry.

FAQ: Cost Structure of Precision Machining

What Are the Main Components of Costs in Precision Machining?

The cost structure of precision machining is divided into direct and indirect costs. Direct costs include raw materials (40-60% of total costs), labor (20-30%), and manufacturing expenses (10-15%). Indirect costs cover management expenses, sales and marketing, and research and development (R&D), typically accounting for 20-30% of total costs. Raw materials, such as titanium or stainless steel, are the largest cost driver due to their high price and processing requirements.

Why Are Raw Material Costs So High in Precision Machining?

Raw materials like titanium Grade 5 ($30–50 per kg) or stainless steel 316L ($5–10 per kg) are expensive due to their specialized properties, such as strength and corrosion resistance, required for industries like aerospace and automotive. Additionally, precision machining often involves small-batch production, limiting bulk purchase discounts. Material waste, ranging from 5-20% depending on the process (e.g., CNC milling vs. turning), and the need for advanced cutting tools ($50–200 per unit) further increase costs.

What Are Manufacturing Expenses in Precision Machining?

Manufacturing expenses include equipment maintenance, energy consumption, and logistics. Advanced equipment, like 5-axis CNC machines ($100,000–500,000 per unit), requires annual maintenance of $5,000–15,000. Energy costs for a medium-sized facility operating 8 hours daily range from $1,000–5,000 monthly, as CNC machines consume 5–20 kW per hour. Logistics, such as shipping 500 kg of components ($500–2,000), and tooling costs ($1,000–5,000 monthly) add to expenses.

What Are Indirect Costs, and Why Do They Matter?

Indirect costs, accounting for 20-30% of total costs, include management expenses, sales and marketing, and R&D. These costs sustain operations and long-term competitiveness. For example, management salaries for a 50-employee facility range from $200,000–500,000 annually, while ERP software ($10,000–50,000 yearly) reduces inefficiencies by 5-10%. Sales efforts, like trade shows ($10,000–50,000 per event), and R&D for new processes ($50,000–100,000 per project) ensure market presence and technical leadership.

What Is the Typical Cost Distribution for a Precision Machining Operation?

For a mid-sized facility with 50 employees producing automotive components, the cost distribution is approximately: raw materials (40-60%, $800,000–1,200,000 annually), labor (20-30%, $400,000–600,000), manufacturing expenses (10-15%, $200,000–300,000), and indirect costs (20-30%, $400,000–600,000). This breakdown varies by industry, scale, and region but highlights key areas for cost optimization.