Custom parts are essential for industries requiring components tailored to specific technical, environmental, and performance needs. These parts demand precise design, specialized materials, tight tolerances, and advanced surface treatments to meet rigorous standards. Below, we explore key industries and their reliance on custom parts to achieve operational excellence.

Aerospace

The aerospace sector demands parts with exceptional precision, temperature resistance, lightweight properties, and reliability. Components like engine parts, airframe structures, and avionics housings are custom-manufactured to comply with stringent standards, ensuring safety and performance in extreme conditions.

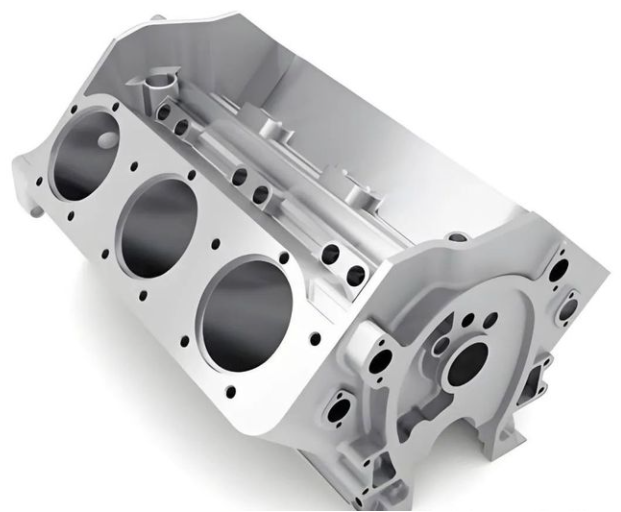

Automotive

In automotive manufacturing, custom parts such as engine components, transmission systems, and body structures are critical for optimizing vehicle performance, fuel efficiency, and safety. These parts are designed to meet the unique requirements of specific models and emerging technologies.

Medical Devices

Medical equipment and implants, including artificial joints, heart valves, and surgical tools, require high biocompatibility, sterility, and precision. Custom parts are produced to exact specifications, often tailored to individual patient needs, ensuring functionality and safety.

Renewable Energy

The renewable energy sector, encompassing wind, solar, and battery technologies, relies on custom parts like precision rotors, solar panel frames, and battery components. These parts are engineered for energy efficiency, weather resistance, and safety, supporting sustainable energy solutions.

Precision Instruments

Optical devices, laboratory equipment, and precision measurement tools require parts with superior accuracy and stability. Custom manufacturing ensures high resolution, repeatability, and reliability, enabling consistent performance in demanding applications.

Semiconductor and Electronics

Semiconductor production and electronics manufacturing demand parts with extreme cleanliness, precision, and corrosion resistance. Custom components for integrated circuits, device packaging, and automation equipment support miniaturization, high performance, and long-term reliability.

Food Processing

Food processing equipment, such as stainless steel conveyors, mixers, and seals, must meet strict safety and hygiene standards. Custom parts are designed with food-safe materials and configurations to ensure compliance and operational efficiency.

Oil and Chemical Processing

In oil and chemical industries, parts like valves, pumps, and reactor internals are exposed to corrosive, high-temperature, and high-pressure conditions. Custom parts are crafted to ensure corrosion resistance, heat tolerance, and reliable sealing.

Heavy Machinery and Construction

Heavy machinery, including excavators and cranes, requires custom structural and transmission components to withstand heavy loads and harsh environments. These parts are engineered for strength, durability, and performance under demanding conditions.

Automation and Robotics

Automation systems and robotic applications, such as production lines, robotic arms, and precision sensors, rely on custom parts to achieve efficient and accurate operations. These components are designed to align with specific workflows and environmental requirements.

Conclusion

Custom parts are integral to meeting the unique demands of diverse industries, from aerospace to automation. By leveraging precise design and specialized materials, these components drive performance, safety, and innovation across applications, shaping the future of industrial manufacturing.