Delrin, a brand name for Polyoxymethylene (POM), is a high-performance engineering thermoplastic valued for its strength, low friction, and dimensional stability. Widely used in industries such as automotive, aerospace, and medical devices, Delrin requires specific machining techniques to achieve precision and avoid material-specific issues. This guide details POM types, machining processes, technical parameters, and key challenges, providing a systematic resource for machinists and engineers.

Understanding Delrin (POM) and Its Types

Polyoxymethylene (POM) is a semi-crystalline thermoplastic with a chemical structure of (-CH₂O-)ₙ, available as homopolymer (POM-H, e.g., Delrin) or copolymer (POM-C, e.g., Celcon). Each type has distinct properties affecting machining strategies. POM-H offers superior mechanical strength and stiffness, while POM-C provides enhanced chemical resistance and lower porosity. Specialty grades, such as glass-filled, low-friction, or UV-stabilized POM, cater to specific applications.

| Property | POM-H (Delrin) | POM-C (Copolymer) |

|---|---|---|

| Tensile Strength | 70-80 MPa | 60-70 MPa |

| Melting Point | 175°C | 165°C |

| Chemical Resistance | Good (solvents, fuels) | Excellent (acids, hot water) |

| Water Absorption | 0.22-0.25% | 0.2-0.4% |

| Machinability | Excellent (Rating: 1/10) | Very Good (Rating: 2/10) |

POM-H is ideal for high-strength components like gears and bearings, while POM-C suits parts exposed to chemicals or moisture. Material selection depends on application requirements and machining constraints.

Key Properties Influencing Delrin Machining

Delrin’s mechanical and physical properties make it highly machinable but require careful handling to optimize results. Key properties include:

- High Strength: Tensile strength of 70-80 MPa (POM-H) supports robust components without deformation.

- Low Friction: Coefficient of friction (0.1-0.3) reduces wear in moving parts like sliders and bushings.

- Dimensional Stability: Low water absorption (0.22-0.25%) ensures tight tolerances in humid conditions.

- Heat Sensitivity: Melting point of 175°C (POM-H) necessitates controlled cutting to avoid thermal damage.

- Chemical Resistance: Resists solvents and fuels, with POM-C excelling in acidic environments.

These properties enable Delrin to replace metals in lightweight, corrosion-resistant applications while maintaining precision.

Delrin Machining Processes

Delrin is compatible with various CNC machining processes, including turning, milling, drilling, threading, and laser cutting. Each process requires specific tools, parameters, and techniques to ensure quality and efficiency.

CNC Turning

Turning shapes Delrin into cylindrical parts like shafts and bushings by rotating the workpiece against a stationary tool.

- Tool Selection: High-speed steel (HSS) or carbide tools with positive rake angles (5-10°) reduce cutting forces. Polished tools minimize friction.

- Cutting Parameters: Spindle speed: 1000-2000 RPM; feed rate: 0.004-0.012 in/rev; depth of cut: 0.02-0.08 in.

- Cooling: Compressed air or water-soluble coolant prevents thermal deformation. Avoid excessive coolant to prevent absorption.

- Clamping: Use minimal pressure to avoid deformation, as Delrin has moderate stiffness (flexural modulus: 2.8-3.0 GPa).

CNC Milling

Milling creates flat surfaces, slots, or complex 3D features like gears and brackets using rotating multi-point tools.

- Tool Selection: Single-flute or two-flute carbide end mills with high rake (10-15°) and clearance angles (10-12°) ensure clean cuts.

- Cutting Parameters: Spindle speed: 1500-3000 RPM; feed rate: 0.008-0.030 in/tooth; cutting speed: 200-250 ft/min.

- Cooling: Compressed air is preferred; minimal water-based coolant may be used for high-speed milling.

- Technique: Climb milling reduces heat and improves surface finish by directing forces into the chip.

Drilling

Drilling creates holes for fasteners or assembly, requiring careful control to avoid cracking or chip clogging.

- Tool Selection: Use sharp HSS or carbide drills with parabolic flutes and point angles of 118-135° for efficient chip evacuation.

- Cutting Parameters: Spindle speed: 1000-2000 RPM; feed rate: 0.002-0.008 in/rev; peck depth: 2-3 times drill diameter.

- Cooling: Compressed air or light coolant prevents heat buildup and clears chips.

- Technique: Peck drilling minimizes chip entanglement and ensures hole accuracy.

Threading

Threading produces internal or external threads for screws or fasteners.

- Tool Selection: Single-point threading tools or polished taps with high relief angles reduce friction.

- Cutting Parameters: Spindle speed: 500-1000 RPM; feed rate synchronized with thread pitch.

- Cooling: Use compressed air or light oil-based coolant to reduce heat and chip adhesion.

Laser Cutting

Laser cutting is used for thin Delrin sheets to create intricate patterns without mechanical stress.

- Equipment: CO2 lasers (10.6 µm wavelength) with power settings of 50-150 W for 1-5 mm thick sheets.

- Parameters: Cutting speed: 10-50 mm/s; pulse frequency: 1000-5000 Hz.

- Considerations: Ensure proper ventilation, as POM releases formaldehyde gas when heated.

Difficulties in Delrin Machining

While Delrin is highly machinable, specific challenges can affect part quality and process efficiency. Addressing these issues is critical for successful outcomes.

| Difficulty | Description | Solution |

|---|---|---|

| Heat Sensitivity | POM’s low melting point (175°C for POM-H) can cause melting or gumming on tools, leading to poor surface finish. | Use sharp tools, lower cutting speeds, and compressed air or minimal coolant. |

| Chip Handling | Continuous, stringy chips can tangle around tools, causing jams or surface defects. | Use chip breakers, peck drilling, or compressed air for chip removal. |

| Dimensional Stability | Machining-induced stress or uneven cooling may cause warping, especially in thin parts. | Anneal parts at 80-100°C for 30-60 minutes to relieve stress. |

| Tool Wear | Reinforced grades (e.g., glass-filled POM) are abrasive, accelerating tool wear. | Use carbide or coated HSS tools and monitor tool condition. |

| Static Electricity | Machining generates static, attracting dust and chips to the workpiece. | Use anti-static coolants or ionizers to maintain a clean workspace. |

Tips for Successful Delrin Machining

To achieve high-quality results, consider the following best practices:

- Optimize Parameters: Test cutting speeds and feeds on scrap material to find the best settings for specific part geometries.

- Use Sharp Tools: Regularly inspect and replace tools to prevent friction-induced heat and poor surface quality.

- Secure Workpiece: Minimize vibration with firm but gentle clamping to avoid deformation.

- Monitor Heat: Use thermocouples or infrared sensors to ensure temperatures remain below 121°C during machining.

- Post-Processing: Deburr edges with fine abrasives and polish for aesthetic or low-friction applications.

Applications of Machined Delrin Parts

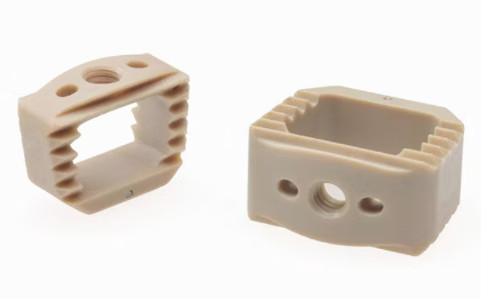

Delrin’s versatility makes it suitable for a wide range of precision components, including:

- Automotive: Gears, fuel system components, and bushings.

- Aerospace: Lightweight brackets and insulators.

- Medical Devices: Surgical instrument handles and valve components.

- Consumer Goods: Zippers, pen components, and conveyor rollers.

By understanding Delrin’s properties and tailoring machining processes to its characteristics, manufacturers can produce durable, high-precision parts efficiently.