Swiss machining, also known as Swiss screw machining or Swiss turning, is a precision manufacturing process widely used in the medical industry for producing high-quality, intricate components. Originally developed in Switzerland for watchmaking, this technology has evolved into a critical tool for crafting medical parts with exceptional accuracy and efficiency. This article examines the key efficiency advantages of Swiss machining for medical parts, emphasizing its precision, speed, material versatility, and quality control, supported by technical details and practical insights.

Unparalleled Precision for Medical Components

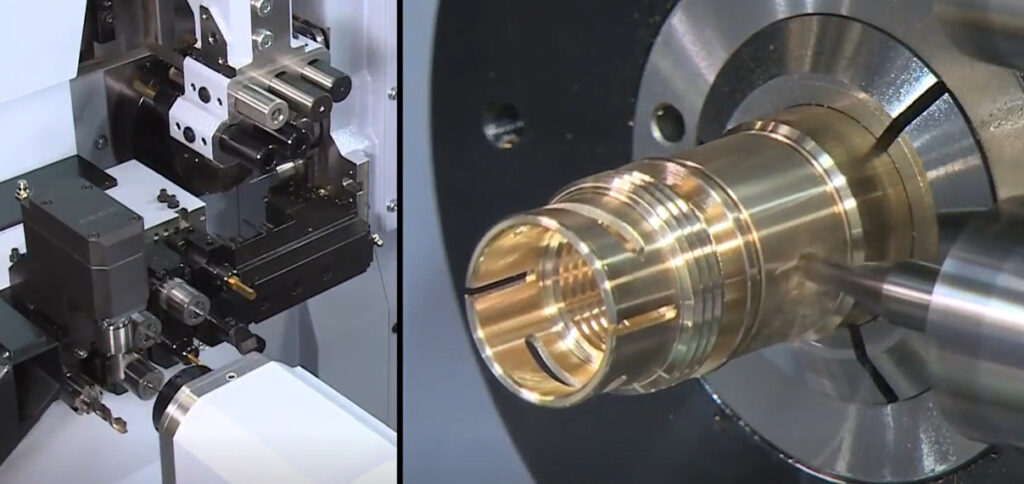

Precision is a cornerstone of medical device manufacturing, where even minor deviations can impact patient safety and device performance. Swiss machining excels in delivering components with tight tolerances, often achieving accuracies as fine as ±0.0005 inches (0.0127 mm). This level of precision is enabled by the unique design of Swiss CNC machines, which feature a sliding headstock and guide bushing. The guide bushing supports the workpiece close to the cutting tool, typically within 0.050 inches (1.27 mm), minimizing vibration and deflection. This stability is critical for producing slender and intricate parts, such as bone screws, dental implants, and orthopedic components, which require exact dimensions to ensure compatibility with human anatomy.

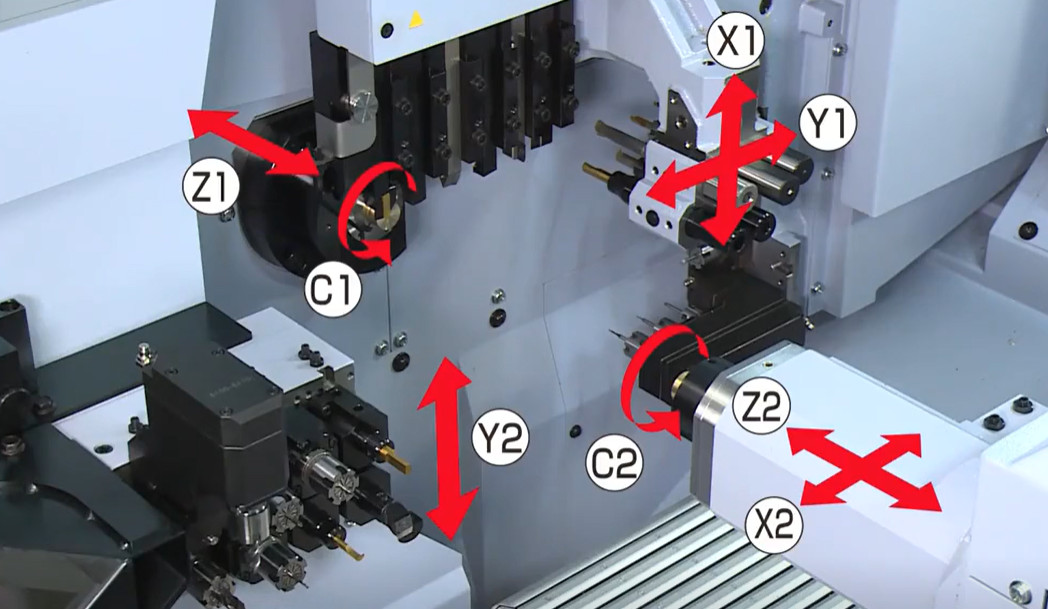

Swiss machining supports multi-axis operations, often incorporating 7 to 13 axes, allowing for simultaneous milling, turning, drilling, and threading. This capability enables the production of complex geometries, such as threads, grooves, and multi-faceted profiles, in a single setup. For example, a surgical instrument with intricate contours can be machined to tolerances of ±0.0002 inches (0.005 mm), ensuring reliable performance in critical applications. The ability to achieve such precision reduces the need for secondary operations, streamlining production and minimizing errors.

High-Speed Production for Reduced Lead Times

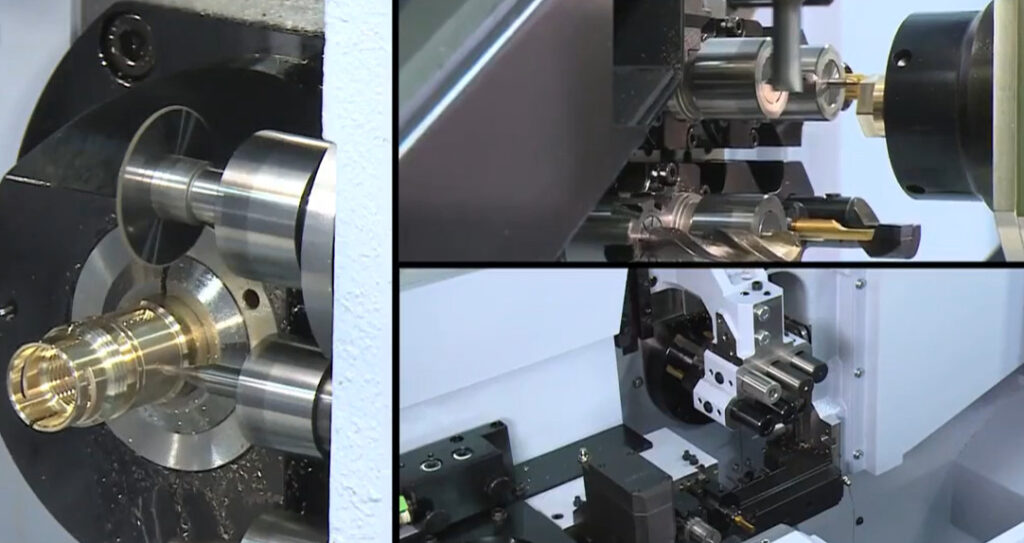

Speed is a critical factor in the medical industry, where rapid delivery of components can accelerate device development and market entry. Swiss machining is designed for high-speed production, leveraging automation and multi-tool configurations to produce parts quickly without compromising quality. CNC Swiss machines operate at high spindle speeds, often exceeding 10,000 RPM, enabling efficient material removal. The use of magazine-style bar feeding systems allows continuous operation, supporting "lights-out" manufacturing for extended periods, which significantly reduces cycle times.

For instance, a Swiss CNC machine can produce a batch of 1,000 bone screws with a diameter of 0.030 inches (0.76 mm) in a fraction of the time required by traditional lathes. The ability to perform multiple operations in a single setup eliminates the need for multiple machine transfers, reducing setup times by up to 50% compared to conventional methods. This efficiency translates to lead times as short as a few hours for small, custom parts, addressing urgent demands in medical emergencies or rapid prototyping.

Material Versatility for Diverse Medical Applications

Medical devices require materials that meet stringent biocompatibility, durability, and corrosion resistance standards. Swiss machining accommodates a wide range of materials, including stainless steel (e.g., 316L and 17-4 PH), titanium, cobalt-chrome alloys, and engineering-grade plastics like PEEK. This versatility allows manufacturers to select materials tailored to specific applications, such as titanium for lightweight implants or PEEK for radiolucent components in imaging devices.

The following table summarizes common materials used in Swiss machining for medical parts, along with their properties and applications:

| Material | Key Properties | Medical Applications |

|---|---|---|

| Stainless Steel (316L) | Corrosion-resistant, biocompatible | Surgical instruments, catheters |

| Titanium | Lightweight, high strength, biocompatible | Orthopedic implants, bone screws |

| PEEK | Radiolucent, chemical-resistant | Spinal implants, imaging components |

| Cobalt-Chrome | High wear resistance, durable | Joint replacements, dental implants |

The ability to machine these materials with minimal tool wear is facilitated by the close proximity of the cutting tool to the guide bushing, which reduces vibration and heat buildup. This ensures consistent quality across high-volume runs, with Swiss machines capable of producing 50 to 500,000 parts while maintaining tolerances within ±0.00025 inches (0.00635 mm).

Enhanced Quality Control and Compliance

Quality assurance is paramount in medical manufacturing, where components must meet strict regulatory standards, such as ISO 9001 and FDA requirements. Swiss machining incorporates advanced technologies, such as real-time monitoring and automated inspection systems, to ensure consistent quality. In-process inspections, using tools like touch probes and laser measurement systems, detect deviations as small as 0.0001 inches (0.00254 mm), allowing for immediate corrections during production.

The stability of Swiss machines, achieved through the guide bushing and sliding headstock, minimizes defects like surface chatter or tool deflection. For example, a Swiss CNC machine can produce a dental implant with a surface finish as fine as 32Ra, reducing the need for post-processing and ensuring compliance with biocompatibility standards. Automated systems also track production data, providing traceability for regulatory audits. This focus on quality control builds trust with medical device manufacturers, ensuring that components meet the exacting demands of healthcare applications.

Cost Efficiency Through Automation and Minimal Waste

Swiss machining offers significant cost advantages, particularly for high-volume production. The ability to complete parts in a single operation reduces labor costs and eliminates the need for multiple setups, which can account for up to 30% of production costs in traditional machining. High-speed spindles and simultaneous multi-tool operations further enhance efficiency, enabling manufacturers to produce complex parts at a lower cost per unit.

Material waste is minimized due to the precision of Swiss machining. For example, when machining titanium, which is expensive and difficult to process, Swiss machines reduce scrap rates to less than 5% compared to 10-15% in conventional methods. The use of bar stock feeding systems optimizes material usage, as only the required length is fed into the cutting area. This efficiency is particularly valuable for medical parts, where material costs can constitute a significant portion of production expenses.

Flexibility for Prototyping and Scalability

Swiss machining is highly adaptable, supporting both prototyping and large-scale production. For prototyping, the ability to produce small, intricate parts with tight tolerances allows engineers to test designs quickly. A single Swiss machine can create a prototype surgical tool with complex features, such as a 0.020-inch (0.508 mm) corner radius, in a matter of hours. This rapid turnaround facilitates iterative design improvements, critical for meeting the medical industry’s evolving needs.

For high-volume production, Swiss machines excel in scalability. They can handle runs ranging from 500 to 500,000 units while maintaining consistent quality. The use of multi-axis machines and automated bar feeders enables continuous production, reducing downtime and ensuring repeatability. For instance, a manufacturer can produce 10,000 orthopedic implants with identical specifications, meeting the demands of large hospital networks without sacrificing precision.

Applications in Medical Device Manufacturing

Swiss machining is widely used to produce a variety of medical components, each requiring specific attributes that leverage the technology’s strengths. The following table highlights key applications and their requirements:

| Component | Key Requirements | Swiss Machining Advantage |

|---|---|---|

| Bone Screws | Tight tolerances (±0.0005 inches), biocompatible materials | High precision, material versatility |

| Surgical Instruments | Complex geometries, smooth finishes (32Ra) | Multi-axis machining, single-setup production |

| Orthopedic Implants | Patient-specific designs, durability | Customizability, high repeatability |

| Imaging Components | Radiolucent materials, precise dimensions | Material flexibility, tight tolerance control |

These applications demonstrate Swiss machining’s ability to meet the medical industry’s diverse needs, from single-use instruments to long-term implants. The technology’s efficiency ensures that manufacturers can deliver components that enhance surgical outcomes and patient care.

Conclusion

Swiss machining offers significant efficiency advantages for producing medical parts, driven by its precision, speed, material versatility, and robust quality control. The technology’s ability to achieve tolerances as tight as ±0.0002 inches, coupled with high-speed production and minimal waste, makes it an ideal choice for medical device manufacturing. Its flexibility supports both prototyping and large-scale production, addressing the industry’s need for rapid innovation and scalability. By leveraging advanced CNC Swiss machines, manufacturers can produce high-quality components that meet stringent regulatory standards, ultimately contributing to improved healthcare outcomes.