Embossing rolls are critical components in industries requiring textured or patterned surfaces on materials like paper, metal, textiles, and plastics. These rolls create raised or recessed designs through pressure, heat, or a combination of both, enhancing aesthetics, functionality, or both. This guide explores the types of embossing rolls, their materials, applications, manufacturing processes, and performance considerations. Detailed technical parameters and practical insights provide a foundation for understanding their role in industrial processes, from packaging to automotive interiors. The focus remains on technical accuracy and applicability across diverse sectors.

Fundamentals of Embossing Rolls

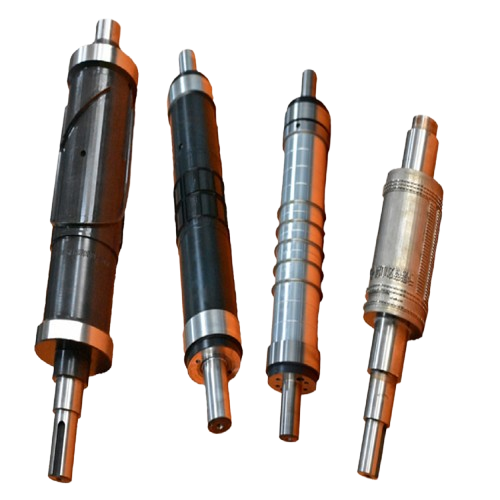

Embossing rolls are cylindrical tools engraved with patterns or textures that transfer designs onto a substrate during a continuous or batch process. The process involves pressing a material between an engraved roll and a counter roll, altering the material’s surface to create a three-dimensional effect. Applications range from decorative enhancements to functional improvements, such as increased strength or absorbency. Understanding the mechanics and design considerations is essential for selecting the appropriate roll for a given task.

Mechanics of Embossing

Embossing relies on mechanical deformation, where pressure forces a material into the engraved pattern of a roll. The counter roll, often smooth or complementary, supports the process by providing resistance. Heat may be applied to soften materials like polymers, ensuring precise pattern transfer. Key parameters include:

- Pressure: Typically 10–40 tonnes across the roll width, adjustable via hydraulic systems.

- Pattern Depth: Ranges from 0.005 mm for fine textures to 4 mm for deep embossing.

- Roll Speed: Up to 1000 m/min for high-speed processes like paper embossing.

The material’s properties, such as elasticity and thickness, influence the embossing outcome, requiring tailored roll designs.

Types of Embossing Processes

Embossing processes vary by material and application. Common methods include:

- Rotary Embossing: Continuous processing using paired rolls, ideal for high-speed production of paper or film.

- Stamp Embossing: Batch processing with flat dies, suited for discrete sheets or semifluid materials.

- Reel-to-Reel Hot Embossing: Used for polymer foils in microsystem applications, with feature sizes of 50–200 µm.

Each method demands specific roll characteristics, discussed in later sections.

Types of Embossing Rolls

Embossing rolls are categorized by their design, engraving method, and pairing with counter rolls. The choice depends on the substrate, desired pattern, and production requirements. This section details common types and their specifications.

Steel-to-Steel Rolls

Steel-to-steel embossing uses matched male and female rolls, both engraved, to create precise patterns. This method suits rigid materials like metal sheets or thick plastics, producing consistent results with minimal material springback. Specifications include:

- Roll Diameter: 80–900 mm.

- Engraving Depth: 0.1–2 mm for most applications.

- Material: Hardened steel (50–60 HRC) for durability.

Applications include metal roofing panels and automotive components.

Rubber-to-Steel Rolls

Rubber-to-steel embossing pairs an engraved steel roll with a smooth rubber counter roll. The rubber’s elasticity allows deeper deformations, ideal for softer materials like paper or thin films. Parameters include:

- Rubber Hardness: 60–90 Shore A.

- Engraving Depth: 0.5–4 mm for pronounced textures.

- Roll Width: Up to 4800 mm for large-scale production.

This method is common in tissue and napkin manufacturing.

Paper-to-Steel Rolls

Paper-to-steel embossing uses a steel roll with a paper-filled counter roll, offering a soft surface for delicate materials. It provides high visual definition, especially for multi-ply paper products. Specifications include:

- Paper Roll Density: 0.6–0.8 g/cm³ for optimal compression.

- Pattern Resolution: 0.01–0.1 mm for fine details.

- Applications: Napkins, towels, and packaging.

Combination Counter Rolls

Combination counter rolls, made of paper, cotton, or wool, provide a soft, adaptable surface for embossing delicate or intricate designs. Wool coatings, with adjustable hardness, suit fine or deep patterns. Parameters include:

- Wool Content: 50–100% for varying softness.

- Roll Diameter: 80–850 mm.

- Applications: Textiles, nonwovens, and luxury packaging.

These rolls are valued for their versatility in handling complex patterns.

Materials for Embossing Rolls

The material of an embossing roll determines its durability, precision, and suitability for specific substrates. Steel, rubber, and specialized coatings dominate, with choices driven by wear resistance, cost, and process conditions.

Steel and Alloys

Hardened steel, often with chrome or nickel plating, is the primary material for engraved rolls due to its strength and wear resistance. Stainless steel suits corrosive environments. Key properties include:

- Tensile Strength: 800–1200 MPa for hardened steel.

- Surface Hardness: 50–60 HRC after heat treatment.

- Plating Thickness: 10–20 µm for chrome or nickel.

Steel rolls handle extreme pressures and are used in metal and plastic embossing.

Rubber and Polymers

Rubber counter rolls, typically made of natural or synthetic rubber, provide flexibility and elasticity. Polyurethane coatings enhance durability. Specifications include:

- Elastic Modulus: 5–10 MPa for rubber.

- Wear Resistance: 10⁷ cycles for high-quality rubber.

- Cost: $2–10/kg compared to $20–50/kg for composites.

Rubber rolls are prevalent in paper and textile applications.

Specialized Coatings

Coatings like Simtex™ (synthetic fiber) or Super Elastic™ (woven cotton) enhance counter roll performance. Simtex™ withstands temperatures above 250°C, enabling high-speed embossing. Parameters include:

- Temperature Resistance: Up to 250°C for Simtex™.

- Coating Thickness: 1–5 mm for cotton or wool.

- Applications: Intricate designs in tissue and nonwovens.

These coatings improve pattern fidelity and roll longevity.

Manufacturing Embossing Rolls

Manufacturing embossing rolls involves precision engraving, material selection, and quality control. Modern techniques like laser engraving have replaced traditional methods, offering greater accuracy and environmental benefits.

Engraving Techniques

Engraving creates the roll’s pattern. Common methods include:

- Laser Engraving: Uses high-power lasers (e.g., Cellaxcy C500) for depths of 0.005–4 mm, with tolerances of ±0.01 mm.

- Chemical Etching: Applies acids to etch patterns, suitable for shallow depths (0.01–0.1 mm).

- Mechanical Knurling: Traditional method for coarse textures, less precise but cost-effective.

Laser engraving dominates due to its precision and eco-friendliness.

Quality Control and Refurbishment

Quality control ensures pattern consistency, with inspections using 3D scanning and test embossing. Refurbishment extends roll life by re-engraving or recoating. Typical refurbishment parameters:

- Re-engraving Depth: 0.1–1 mm to restore patterns.

- Cost Savings: 30–50% compared to new rolls.

Regular maintenance prevents downtime and maintains production quality.

Applications of Embossing Rolls

Embossing rolls serve diverse industries, enhancing both aesthetic and functional properties of materials. This section explores key applications and their requirements.

Paper and Tissue Products

Paper embossing enhances texture, absorbency, and visual appeal in products like napkins, towels, and packaging. Parameters include:

- Pattern Depth: 0.1–1 mm for tactile effects.

- Roll Speed: 500–1000 m/min for high-volume production.

- Materials: Tissue, cardboard, and wrapping paper.

Multi-ply tissue products benefit from increased bulk and softness.

Metal and Plastics

Metal embossing increases strength-to-weight ratios for applications like roofing and automotive panels. Plastic embossing is used in packaging and medical products. Specifications include:

- Material Thickness: 0.1–2 mm for metals, 0.05–0.5 mm for plastics.

- Pattern Types: Linear, honeycomb, or pyramid.

These patterns improve structural integrity and aesthetic appeal.

Textiles and Nonwovens

Textile embossing, such as Schreiner finishes, enhances luster and texture for garment linings. Nonwovens benefit from increased thickness and absorbency. Parameters include:

- Pressure: Up to 40 tonnes for textile substrates.

- Engraving Angle: 30–45° for Schreiner patterns.

Applications include medical textiles and hygiene products.

Performance Optimization

Optimizing embossing roll performance involves balancing pattern fidelity, roll durability, and process efficiency. Key considerations include:

- Counter Roll Hardness: Softer rolls (e.g., rubber) improve flatness in polymer foils.

- Maintenance: Regular cleaning and re-engraving extend roll life by 20–30%.

- Simulation: Vibration analysis reduces pattern distortion at high speeds.

Advanced techniques, such as real-time monitoring, enhance consistency in high-speed production.

Frequently Asked Questions

What materials can be embossed with embossing rolls?

Embossing rolls can process paper, metal, textiles, plastics, nonwovens, and leather, provided the material is malleable and the roll is designed for the specific substrate.

Which engraving method is most precise?

Laser engraving offers the highest precision, with tolerances of ±0.01 mm and depths from 0.005–4 mm, making it ideal for intricate patterns.

How long do embossing rolls last?

With proper maintenance, steel rolls last 10⁷–10⁸ cycles, while rubber or coated rolls may require refurbishment after 10⁶ cycles.

What are common challenges in embossing?

Issues include pattern distortion, material springback, and roll wear, often mitigated by precise engraving and optimized counter roll materials.

How is roll refurbishment performed?

Refurbishment involves re-engraving, recoating, or journal repair, restoring patterns at 30–50% of the cost of new rolls.