Coordinate Measuring Machines (CMMs) are essential for verifying the roundness of vacuum pump blades, critical components in high-precision systems like dry vacuum pumps. Roundness tolerances, often within 3–5 micrometers (0.00012–0.00020 inches), directly impact performance, efficiency, and durability. This article provides a detailed, technical guide on using CMMs to measure and ensure blade roundness, covering equipment setup, measurement techniques, data analysis, and practical considerations. The content emphasizes systematic processes, reliability, and professionalism, avoiding speculative topics like trends or innovations, with specific parameters to support precision manufacturing.

Importance of Roundness in Vacuum Pump Blades

Roundness, as defined by ISO 1101, measures how closely a blade’s cross-sectional profile conforms to a perfect circle, quantified as the radial distance between two concentric circles enclosing the profile. For vacuum pump blades, roundness is critical because deviations cause vibration, uneven wear, or reduced sealing efficiency, particularly in oil-free pumps operating at high speeds (e.g., 10,000–15,000 RPM). A deviation of 4 micrometers can lead to performance losses or premature failure, impacting pump reliability.

CMMs measure roundness by collecting coordinate data along the blade’s circular edge and analyzing it with fitting algorithms, such as Least Square Circle (LSC), Minimum Circumscribed Circle (MCC), Maximum Inscribed Circle (MIC), or Minimum Zone Circles (MZC). These methods ensure compliance with tolerances, typically 3–5 micrometers, supporting efficient pump operation.

CMM Configuration for Roundness Measurement

Accurate roundness measurement requires precise CMM setup, including machine components, calibration, and environmental controls. A well-configured CMM achieves repeatability within 0.5–1.5 micrometers, essential for precision blades.

CMM Components and Fixturing

A CMM consists of a granite base for thermal stability, a bridge or gantry for axis movement, and a probe system for data collection. Tactile probes, such as ruby-tipped styluses (0.5–1.5 mm diameter), are preferred for vacuum pump blades due to their precision, achieving repeatability of 0.3–0.5 micrometers. Non-contact probes (e.g., laser or optical) are used for delicate materials to prevent surface damage. The machine’s X, Y, and Z axes, driven by servo motors with linear encoders, provide positioning accuracy of 0.1–0.3 micrometers.

Fixturing ensures the blade remains stationary without deformation. For blades with diameters of 20–100 mm, V-blocks (90° or 120° angles) or magnetic clamps align the blade’s axis with the CMM’s coordinate system. Misalignment can introduce errors up to 2 micrometers, so fixtures must be rigid and precisely positioned. Air bearings minimize friction, critical for tolerances below 4 micrometers.

Calibration and Environmental Control

Calibration uses traceable standards, like a 25 mm certified sphere, to verify probe accuracy and machine alignment, ensuring measurement uncertainty within 0.5–1 micrometer. Calibration corrects for stylus wear or probe misalignment. Environmental conditions are tightly controlled: temperature at 20°C ± 0.5°C, humidity at 40–60%, and vibration minimized using isolation systems. For steel blades (thermal expansion coefficient of 11.7 µm/m/°C), a 1°C deviation can cause a 1.2 micrometer error on a 100 mm diameter, necessitating stable conditions.

Measurement Techniques for Roundness

Roundness measurement involves strategic sampling, probe selection, and fitting algorithms to detect form errors like ovality or lobing accurately.

Data Sampling Strategies

The number and distribution of data points affect measurement accuracy. ISO 12181 recommends at least 4 points for basic roundness, but vacuum pump blades require 50–100 points for discrete measurements or 2000–5000 points for scanning. For a 50 mm diameter blade, 100 points (3.6° intervals) detect common defects, while scanning at 10 points per mm captures fine deviations, suitable for tolerances below 3 micrometers.

Pulse measurement, using touch-trigger probes, is efficient for initial inspections, capturing 50 points in 8–10 seconds. Scanning measurement, using continuous probes, provides detailed profiles for critical blades, collecting 3000 points in 30–50 seconds. Uniform point distribution prevents sampling bias, and software compensates for probe radius or stylus deflection to ensure accuracy.

Fitting Algorithms

Fitting algorithms calculate roundness error by comparing measured points to an ideal circle. The primary methods are:

| Algorithm | Description | Application |

|---|---|---|

| Least Square Circle (LSC) | Minimizes squared deviations from a mean circle | Production environments, fast and reliable |

| Minimum Circumscribed Circle (MCC) | Smallest circle enclosing all points | Outer diameters, maximum material condition |

| Maximum Inscribed Circle (MIC) | Largest circle within all points | Inner diameters, minimum material condition |

| Minimum Zone Circles (MZC) | Minimizes radial distance between concentric circles | High-precision, tolerances below 3 micrometers |

MZC is preferred for vacuum pump blades with tight tolerances due to its accuracy, while LSC is common in high-throughput settings for its computational efficiency.

Probe Types and Measurement Modes

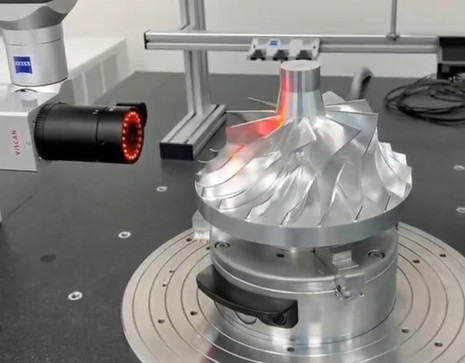

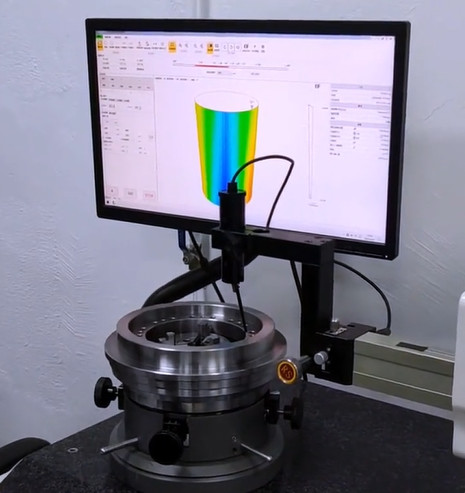

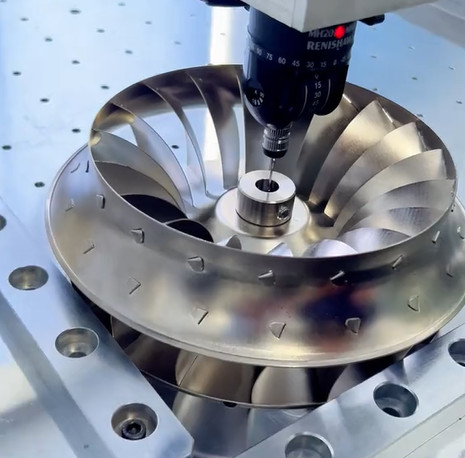

Tactile probes, like the Renishaw TP20 with a 1 mm stylus, offer repeatability of 0.3 micrometers, suitable for most blades. Scanning probes, such as the Zeiss VAST XT, collect data at 3–6 mm/s, ideal for tolerances below 3 micrometers. Touch-trigger mode captures discrete points (e.g., 80 points in 10 seconds), while scanning mode provides continuous data for detailed analysis. Scanning is recommended for detecting subtle form errors in high-precision blades.

Analyzing Roundness Data

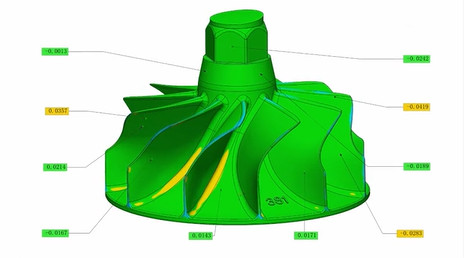

CMM software processes coordinate data to generate roundness metrics, including error, center offset, and form deviations. Key steps include:

Filtering: Gaussian filters (15–50 UPR cutoff) remove noise from surface roughness or vibrations, preserving true roundness data. For a 50 mm blade, a 15 UPR filter isolates low-frequency errors like ovality.

Error Calculation: Roundness error is the radial difference between the outermost and innermost points relative to the fitted circle. A 3.0 micrometer error on a 50 mm blade indicates compliance with a 4 micrometer tolerance.

Reporting: Software generates polar plots and numerical reports, detailing deviations and compliance with ISO 1101 or ASME Y14.5 standards. Reports include pass/fail criteria, ensuring traceability.

Practical Considerations for Reliable Measurements

Reliable measurements require attention to practical factors:

Fixture Alignment: Fixtures must align the blade’s axis with the CMM’s coordinate system. For a 40 mm blade, a 120° V-block ensures stability within 0.4 micrometers. Misalignment can cause errors up to 1.5 micrometers.

Probe Maintenance: Clean styluses daily to remove debris. For carbon or ceramic blades, non-contact probes (e.g., laser) prevent surface damage. A 0.8 mm stylus suits most applications.

Measurement Speed: Scanning at 2–4 mm/s is recommended for tolerances below 4 micrometers to minimize dynamic errors. Higher speeds (e.g., 7 mm/s) are used for less réunion pour les inspections moins critiques.

Operator Training: Operators need expertise in CMM programming, calibration, and data interpretation. Training reduces errors, such as incorrect probe orientation or software misconfiguration.

Key Considerations for Measurement Accuracy

Certain factors can impact measurement reliability if not addressed:

| Consideration | Impact | Mitigation |

|---|---|---|

| Thermal Variation | Causes dimensional changes | Maintain 20°C ±0.5°C, use compensation algorithms |

| Vibration | Introduces measurement noise | Use vibration isolation tables |

| Probe Wear | Reduces accuracy | Calibrate probes daily, replace worn styluses |

| Fixture Stability | Misalignment skews data | Use precision fixtures, verify alignment |

Addressing these ensures consistent, high-accuracy measurements for vacuum pump blades.

Case Study: Roundness Measurement of a Vacuum Pump Blade

A 45 mm diameter blade with a 3.5 micrometer roundness tolerance is measured using a Hexagon Global S CMM with a 1 mm ruby-tipped probe. The blade is secured in a 90° V-block, and 2500 points are collected via scanning at 3 mm/s. The MZC algorithm calculates a roundness error of 3.0 micrometers, with minor ovality detected. The blade passes inspection, and a polar plot confirms compliance with ISO 1101. In another case, a 100-point pulse measurement on a 50 mm blade reveals a 4.5 micrometer error, indicating a machining issue. Adjustments to the grinding process reduce the error to 3.3 micrometers, meeting tolerance.

Conclusion

Using CMMs to ensure the roundness of vacuum pump blades is a precise, systematic process that integrates advanced equipment, strategic measurement techniques, and rigorous data analysis. Proper setup, including calibration and fixturing, combined with optimized sampling and fitting algorithms, achieves sub-micron accuracy. Practical considerations, such as probe maintenance and environmental control, address potential limitations, ensuring reliable results. This approach supports high-quality manufacturing, meeting stringent tolerances and enhancing vacuum pump performance and durability.