Fasteners are mechanical components used to join or secure materials together, playing a critical role in industries such as construction, automotive, aerospace, and manufacturing. They provide structural integrity, ease of assembly, and, in some cases, the ability to disassemble components. This comprehensive overview details the primary types of fasteners, their specifications, and their applications across various sectors, emphasizing technical characteristics and practical uses.

Bolts

Bolts are threaded fasteners designed to create strong, reliable joints when used with nuts. They consist of a cylindrical shank with external threads and a head, typically hexagonal, square, or round, for wrench application. Bolts are commonly made from materials like carbon steel, stainless steel, or alloy steel, with grades indicating strength, such as Grade 5 or Grade 8 for SAE standards, or 8.8, 10.9, and 12.9 for metric standards.

Bolts are used in applications requiring high tensile strength, such as structural steel frameworks, machinery assembly, and heavy equipment. For example, hex bolts are widely used in construction for steel beam connections, with diameters ranging from 1/4 inch to over 1 inch and lengths up to 12 inches or more, depending on the application. Carriage bolts, with a smooth, domed head and square neck, are used in wood-to-metal connections, preventing rotation during tightening. Anchor bolts secure structures to concrete foundations, with L-shaped or headed designs to resist pullout forces.

| Bolt Type | Material | Typical Diameter | Applications |

|---|---|---|---|

| Hex Bolt | Carbon Steel, Stainless Steel | 1/4" - 1" | Structural connections, machinery |

| Carriage Bolt | Carbon Steel, Galvanized | 1/4" - 3/4" | Wood-to-metal joints |

| Anchor Bolt | Stainless Steel, Alloy Steel | 3/8" - 1-1/4" | Concrete foundations |

Screws

Screws are threaded fasteners that create their own mating thread when driven into materials. Unlike bolts, screws typically do not require a nut and are designed for direct insertion into pre-drilled or pre-tapped holes. Common materials include stainless steel, brass, and zinc-plated steel, with thread types such as coarse (UNC) or fine (UNF) affecting holding strength.

Machine screws, with uniform threads, are used in metal-to-metal applications, such as securing components in electronics or machinery, with sizes ranging from #0 (0.060 inches) to #12 (0.216 inches). Wood screws, featuring coarse threads and a tapered point, are designed for wood applications, providing strong grip in materials like oak or pine. Self-tapping screws, which cut their own threads, are used in sheet metal or plastic, with lengths typically from 1/4 inch to 3 inches. Drywall screws, with bugle heads, are optimized for attaching drywall to studs, minimizing surface damage.

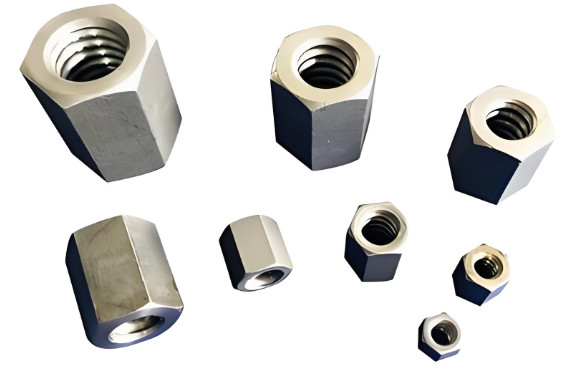

Nuts

Nuts are internally threaded fasteners that pair with bolts to create secure joints. They come in various shapes, including hexagonal, square, and wing nuts, and are made from materials like carbon steel, stainless steel, or nylon for corrosion resistance. Nuts are specified by thread size, such as M6 (6mm) or 1/4-20 (1/4 inch diameter, 20 threads per inch), and strength grades matching bolts.

Hex nuts are the most common, used in automotive and construction applications for their ease of tightening with a wrench. Lock nuts, such as nylon-insert or all-metal prevailing torque nuts, prevent loosening under vibration, making them suitable for machinery or vehicle assemblies. Wing nuts allow hand-tightening, ideal for temporary fixtures or equipment requiring frequent adjustments, like stage lighting or scaffolding.

Washers

Washers are flat, disc-shaped components placed under bolts or nuts to distribute load, prevent surface damage, or reduce friction. Common types include flat washers, lock washers, and spring washers, typically made from steel, stainless steel, or non-metallic materials like nylon. Flat washers, with standard sizes like SAE or USS, are used to protect surfaces and ensure even load distribution in structural assemblies. Lock washers, such as split or toothed designs, resist loosening under vibration, commonly used in automotive and aerospace applications. Spring washers, with a curved or wave design, maintain tension in assemblies subject to thermal expansion or contraction.

Rivets

Rivets are permanent fasteners used to join materials, typically metal sheets or plates, by deforming the rivet end to create a secure joint. They are made from materials like aluminum, steel, or copper and are available in solid, blind, or tubular forms. Solid rivets, with diameters from 1/16 inch to 1/2 inch, are used in structural applications like bridge construction, requiring high shear strength. Blind rivets, or pop rivets, are installed from one side, making them ideal for sheet metal assemblies in aerospace or automotive panels, with grip ranges from 1/8 inch to 1 inch. Tubular rivets, with a hollow shank, are used in leather or fabric applications, such as luggage or upholstery.

Pins

Pins are non-threaded fasteners used to align, secure, or limit movement in assemblies. Common types include dowel pins, cotter pins, and clevis pins, typically made from steel or stainless steel. Dowel pins, with precise diameters like 1/8 inch to 1 inch, ensure accurate alignment in machinery or furniture assembly. Cotter pins, with a split design, secure other fasteners like bolts or clevis pins in agricultural or automotive equipment. Clevis pins, used with a cotter pin or retaining ring, create pivot points in mechanical linkages, such as in heavy machinery or towing systems.

Clips and Clamps

Clips and clamps provide temporary or semi-permanent fastening solutions, often used where disassembly is required. Spring clips, like E-clips or snap rings, secure components on shafts or within bores, common in automotive or machinery applications, with sizes ranging from 1/8 inch to 2 inches in diameter. Hose clamps, typically stainless steel or galvanized, secure hoses to fittings in plumbing or automotive systems, with adjustable diameters from 1/2 inch to 6 inches. Cable ties, made of nylon, are used for bundling wires or securing components in electronics or construction, with tensile strengths from 50 to 250 pounds.

Adhesive Fasteners

Adhesive fasteners, such as epoxy or acrylic-based bonding systems, provide non-mechanical joining solutions for materials like composites, plastics, or metals. They are used in applications requiring seamless joints, such as automotive body panels or aerospace composites, with shear strengths ranging from 1,000 to 4,000 psi depending on the adhesive type. Adhesive fasteners eliminate the need for drilling or mechanical fasteners, reducing weight and stress concentrations, but require proper surface preparation for optimal bonding.

Specialty Fasteners

Specialty fasteners are designed for specific applications or environments. For example, tamper-resistant screws, with unique head designs like Torx or pin-in-hex, prevent unauthorized removal, used in security equipment or public infrastructure. High-temperature fasteners, made from materials like Inconel or titanium, withstand temperatures up to 1,500°F, suitable for aerospace or industrial furnaces. Marine-grade fasteners, typically 316 stainless steel, resist corrosion in saltwater environments, used in boat construction or offshore platforms.

| Specialty Fastener | Material | Key Feature | Applications |

|---|---|---|---|

| Tamper-Resistant Screw | Stainless Steel | Unique head design | Security equipment |

| High-Temperature Bolt | Inconel, Titanium | Heat resistance up to 1,500°F | Aerospace, furnaces |

| Marine-Grade Fastener | 316 Stainless Steel | Corrosion resistance | Marine, offshore |

Material Selection Considerations

Fastener material selection depends on the application environment and load requirements. Carbon steel offers high strength but is prone to corrosion, requiring coatings like zinc or galvanization. Stainless steel, particularly 304 or 316 grades, provides excellent corrosion resistance for outdoor or marine use. Alloy steels, like those used for Grade 8 bolts, offer superior tensile strength for high-load applications. Non-metallic fasteners, such as nylon or plastic, are used in low-load, corrosion-sensitive environments like electronics.

Installation and Performance Factors

Proper installation is critical to fastener performance. Thread engagement, torque specifications, and surface preparation affect joint strength. For example, bolts require a minimum thread engagement of 1.5 times the diameter to ensure full strength. Over-torquing can lead to thread stripping, while under-torquing may cause loosening. Washers and lock nuts enhance joint reliability in dynamic environments. For rivets, proper setting tools and techniques ensure consistent deformation and joint strength.

Standards and Specifications

Fasteners adhere to standards like ASME, ISO, or DIN, which define dimensions, materials, and performance. For instance, ASME B18.2.1 specifies hex bolt dimensions, while ISO 898-1 defines mechanical properties for metric fasteners. Compliance with these standards ensures compatibility and reliability across applications. Manufacturers provide detailed specifications, such as tensile strength (e.g., 120,000 psi for Grade 8 bolts) or shear strength, to guide selection.

Fasteners: Types and Applications FAQ

What are fasteners?

Fasteners are hardware devices that mechanically join or secure two or more objects together. They come in various types and are used in a wide range of applications across different industries.

How do I choose the right fastener for my project?

Consider the following factors when selecting a fastener:

Material: Choose a material that suits the environment (e.g., corrosion resistance).

Load Requirements: Determine the strength needed based on the load the fastener will bear.

Application: Consider the specific use case (e.g., indoor vs. outdoor, permanent vs. temporary).

Ease of Installation: Some fasteners require special tools or techniques for installation.

Can fasteners be reused?

Some fasteners, like screws and bolts, can be reused if they are in good condition. However, others, like rivets, are typically permanent and cannot be reused once installed. Always inspect reused fasteners for damage before reinstallation.

Where can I buy fasteners?

Fasteners can be purchased at hardware stores, home improvement centers, and online retailers. Specialty fastener suppliers may also offer a wider variety of options for specific custom applications.