Glass machining is a specialized manufacturing process that shapes, cuts, drills, or finishes glass to meet precise specifications. Due to glass's brittle nature, machining requires advanced techniques, specialized tools, and controlled parameters. This guide provides a systematic overview of glass machining, including its types, processes, key parameters, and inherent difficulties, tailored for professionals in industries such as optics, electronics, and aerospace.

Overview of Glass Machining

Glass machining involves removing material from glass workpieces to achieve desired shapes, dimensions, or surface finishes. Unlike metals or plastics, glass's hardness and brittleness necessitate unique approaches to avoid cracking or chipping. Common applications include optical lenses, electronic substrates, and architectural components. The process typically employs computer numerical control (CNC) machines, diamond tools, and abrasive techniques to ensure precision.

Key considerations in glass machining include material type (e.g., soda-lime, borosilicate, fused silica), thickness, and tolerance requirements. Machining processes are selected based on part complexity, volume, and end-use specifications. The following sections detail the primary types of glass machining, their technical parameters, and associated difficulties.

Types of Glass Machining

Glass machining encompasses various techniques, each suited to specific geometries, tolerances, and applications. Below are the primary types, along with their processes and parameters.

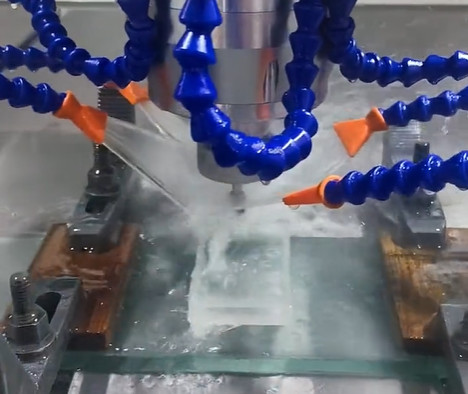

CNC Milling

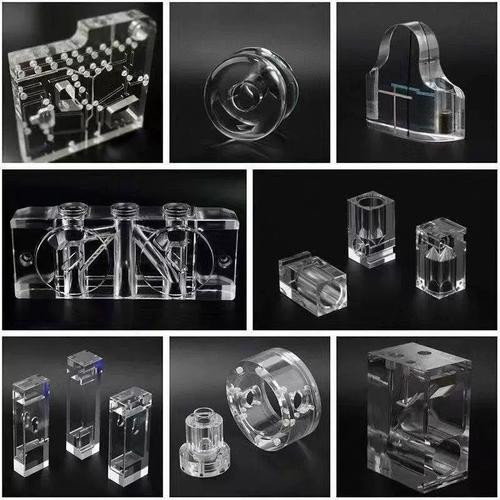

CNC milling uses rotating diamond tools to remove material from a glass workpiece, creating complex shapes like slots, pockets, or contours. Multi-axis CNC mills (3- to 5-axis) enable simultaneous cutting from multiple angles, reducing setup time. This method is ideal for producing intricate parts such as optical prisms or aerospace components.

Key Parameters:

- Spindle Speed: 10,000–40,000 RPM, depending on glass type and tool.

- Feed Rate: 0.01–0.1 mm/rev to minimize fracture risk.

- Depth of Cut: 0.05–0.5 mm per pass for brittle glasses like fused silica.

- Tool Material: Polycrystalline diamond (PCD) for wear resistance.

- Coolant: Water-based or oil-based to reduce thermal stress.

Applications: Optical lenses, microfluidic devices, and precision molds.

CNC Turning

CNC turning rotates the glass workpiece against a stationary diamond tool, producing cylindrical parts like rods or tubes. This method is less common for glass due to its brittleness but is used for components requiring rotational symmetry.

Key Parameters:

- Spindle Speed: 500–2,000 RPM to avoid vibration-induced cracks.

- Feed Rate: 0.005–0.05 mm/rev for surface finish control.

- Depth of Cut: 0.02–0.2 mm to prevent chipping.

- Tool Type: Single-point diamond tool for precision.

- Coolant: High-pressure coolant to dissipate heat.

Applications: Glass tubing for medical devices and optical fibers.

Grinding

Grinding employs abrasive wheels to achieve smooth surfaces or tight tolerances. It is often used for flat glass or optical components requiring high surface quality. Grinding can be performed on CNC or manual machines, with diamond-impregnated wheels for efficiency.

Key Parameters:

- Wheel Speed: 1,500–3,000 m/min for diamond wheels.

- Feed Rate: 0.01–0.05 mm/pass for minimal subsurface damage.

- Depth of Cut: 0.001–0.01 mm for finishing passes.

- Abrasive Type: Diamond grit (140/170 mesh for roughing, 325/400 for finishing).

- Coolant: Continuous flow to prevent thermal cracking.

Applications: Touchscreen substrates, telescope mirrors, and glass wafers.

Drilling

Glass drilling uses diamond core drills or ultrasonic tools to create holes for fasteners or optical assemblies. Abrasive jet drilling (AJD) is an alternative for micro-holes, using high-pressure abrasive-laden gas.

Key Parameters:

- Spindle Speed: 1,000–5,000 RPM for core drills.

- Feed Rate: 0.005–0.02 mm/rev to avoid edge chipping.

- Hole Diameter: 0.017–50 mm, depending on tool.

- Abrasive Jet Pressure: 0.2–0.7 MPa for AJD.

- Coolant: Water to lubricate and cool the drilling zone.

Applications: Glass panels for architectural fittings and electronic displays.

Water Jet Cutting

Water jet cutting uses high-pressure water mixed with abrasives to cut complex shapes in glass. It is suitable for thick glass (2–50 mm) and offers flexibility for intricate designs without thermal stress.

Key Parameters:

- Pressure: 200–400 MPa for efficient cutting.

- Abrasive Flow Rate: 0.3–0.6 kg/min (garnet abrasive).

- Feed Rate: 50–500 mm/min, based on thickness.

- Nozzle Diameter: 0.5–1.2 mm for precision.

- Standoff Distance: 1–3 mm to optimize cut quality.

Applications: Decorative glass panels and automotive windshields.

Key Machining Parameters

Optimizing machining parameters is critical to achieving high-quality glass components. The table below summarizes typical parameters for common glass machining processes.

| Process | Spindle/Wheel Speed | Feed Rate | Depth of Cut | Tool/Abrasive | Coolant |

|---|---|---|---|---|---|

| CNC Milling | 10,000–40,000 RPM | 0.01–0.1 mm/rev | 0.05–0.5 mm | PCD | Water-based |

| Grinding | 1,500–3,000 m/min | 0.01–0.05 mm/pass | 0.001–0.01 mm | Diamond (140/170 mesh) | Continuous water |

| Drilling | 1,000–5,000 RPM | 0.005–0.02 mm/rev | N/A | Diamond core drill | Water |

| Water Jet Cutting | N/A | 50–500 mm/min | N/A | Garnet abrasive | Water |

Difficulties in Glass Machining

Glass machining presents several technical difficulties due to its material properties. Addressing these requires precise control, specialized equipment, and skilled operators. The following are key difficulties encountered during glass machining.

Brittle Fracture

Glass’s low fracture toughness (0.7–0.9 MPa·m¹/² for soda-lime) makes it prone to cracking during machining. Excessive cutting forces or improper parameters can initiate microcracks, leading to part failure. To mitigate this, low feed rates and shallow depths of cut are used, alongside high-pressure coolants to reduce stress concentrations.

Tool Wear

The abrasive nature of glass accelerates tool wear, particularly for diamond tools. For example, milling fused silica can reduce tool life by 30% compared to softer glasses. Regular tool inspection and replacement are necessary, with wear-resistant coatings (e.g., TiAlN) extending tool life by up to 20%.

Surface and Subsurface Damage

Machining can introduce surface scratches or subsurface microcracks, degrading optical or mechanical performance. Grinding with fine diamond grit (325/400 mesh) and polishing with cerium oxide slurries can achieve surface roughness (Ra) below 0.01 µm, minimizing damage.

Thermal Stress

Localized heating during machining can induce thermal cracks, especially in glasses with low thermal conductivity (e.g., 1.1 W/m·K for soda-lime). Continuous coolant application and optimized cutting speeds (e.g., 100 m/min for milling) help dissipate heat and prevent cracking.

Chip Removal

Fine glass chips can accumulate in the cutting zone, causing tool clogging or surface scratches. Efficient chip removal systems, such as vacuum suction or high-pressure air jets, are essential to maintain machining quality.

Best Practices for Glass Machining

To achieve high-quality results, manufacturers should adopt the following practices:

- Tool Selection: Use diamond-based tools with high wear resistance for extended life and precision.

- Parameter Optimization: Employ Taguchi or ANOVA methods to identify optimal spindle speed, feed rate, and depth of cut for specific glass types.

- Quality Control: Implement coordinate measuring machines (CMMs) and optical microscopy to verify tolerances and surface quality.

- Workholding: Use vacuum chucks or specialized fixtures to secure glass without inducing stress.

- Post-Processing: Apply polishing or annealing to remove residual stresses and enhance surface finish.

Conclusion

Glass machining is a complex process requiring advanced techniques, precise parameters, and specialized tools to overcome the material’s brittleness and hardness. By understanding the types of machining—such as CNC milling, grinding, drilling, and water jet cutting—along with their parameters and difficulties, manufacturers can achieve high-precision components for demanding applications. Effective management of brittle fracture, tool wear, and thermal stress, combined with rigorous quality control, ensures consistent and reliable results in glass machining.