This article provides a comprehensive guide on utilizing an existing tool grinder to grind the minor diameters of rectangular splines in small-batch production. By designing an effective fixture, this method eliminates the need for specialized equipment, ensuring that design tolerances are met while maintaining cost efficiency. The process leverages the capabilities of a standard tool grinder, specifically the MQ6025A model, to achieve precise machining of spline shafts with a minor diameter of φ90mm and strict symmetry requirements.

Introduction to Rectangular Spline Shafts

Rectangular spline shafts are widely used in mechanical transmissions due to their high load-carrying capacity, excellent centering, and guiding properties. These characteristics stem from their multi-tooth design, which distributes forces evenly across the spline. Common machining methods for splines include milling, hobbing, grinding, and plastic deformation techniques such as cold forging or rolling. For hardened spline shafts centered on their minor diameter, grinding on a dedicated spline grinder is typically the preferred method to ensure precision. However, for small-batch production, investing in specialized equipment may not be feasible, prompting the need for alternative solutions.

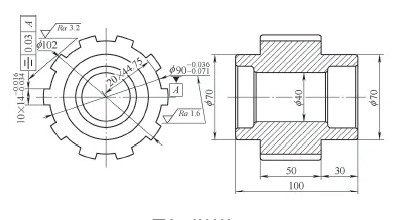

In this case, the spline shaft in question has a minor diameter of φ90mm, which serves as the assembly datum. The design specifies a symmetry tolerance of 0.03mm between the spline tooth width and the minor diameter, with a required hardness of 45–50 HRC after quenching. The annual production volume is limited to 300 pieces, making the acquisition of a dedicated spline grinder economically unviable.

Problem Statement

The company faced a significant issue with its spline shaft production. Since 2004, the manufacturing process, from raw material to finished part, was outsourced due to the lack of in-house spline grinding capabilities. In May 2016, market feedback indicated severe wear and reduced service life of the spline shafts. Investigation revealed that the subcontractor had altered the material composition, resulting in hardness levels below the specified requirements. This incident highlighted the risks of outsourcing small-batch production to larger subcontractors, who may prioritize high-volume orders over quality control for smaller contracts. To ensure product quality and delivery reliability, the company decided to transition to in-house manufacturing without investing in specialized equipment.

Development of the Machining Process

To achieve in-house production, the team explored cost-effective methods to machine the spline shaft using existing equipment. The primary challenge was grinding the minor diameter of the spline, as the company lacked a dedicated spline grinder. After reviewing various machining techniques, inspiration was drawn from single-point milling of rectangular spline teeth. The proposed solution involved two key strategies:

- Machining the spline tooth flanks using a straight-tooth, three-sided milling cutter or a vertical milling cutter.

- Grinding the minor diameter using a formed concave arc grinding wheel.

The finalized process flow for the spline shaft is as follows:

- Turning the external profile of the shaft.

- Rough milling the spline tooth flanks and minor diameter on a milling machine.

- Quenching to achieve the required hardness (45–50 HRC).

- Grinding the centering hole (φ40mm) and both end faces to ensure total length accuracy.

- Precision milling of the spline tooth flanks and shoulders using a machining center with mandrel clamping.

- Grinding the spline minor diameter using a concave arc formed grinding wheel with mandrel clamping.

All steps except the minor diameter grinding could be performed using existing equipment. The challenge was to adapt the MQ6025A tool grinder, typically used for tool sharpening, to perform the minor diameter grinding operation.

Fixture Design for Minor Diameter Grinding

The MQ6025A tool grinder was selected for its ability to rotate the grinding wheel and provide axial feed, which are essential for grinding operations. However, the grinder lacked a mechanism for indexing the spline shaft circumferentially. To address this, a custom fixture was designed to enable precise indexing and positioning of the spline shaft during grinding.

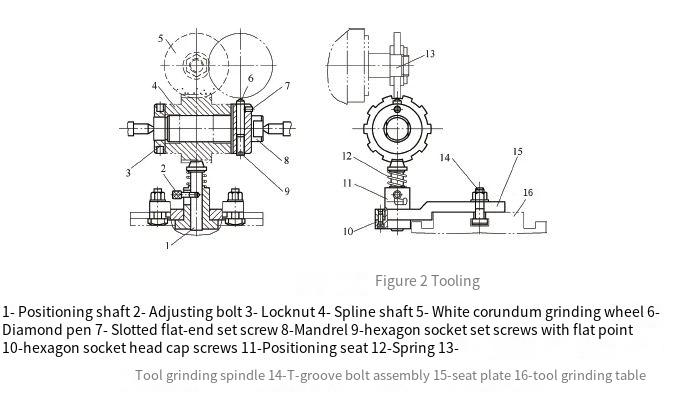

The fixture setup, as illustrated in the schematic, includes the following components:

| Component | Description |

|---|---|

| Positioning Shaft | Ensures circumferential alignment during indexing. |

| Adjusting Bolt | Facilitates manual indexing by pulling the positioning shaft. |

| Locking Nut | Secures the adjusting bolt in position. |

| Spline Shaft | The workpiece, clamped on a mandrel. |

| White Corundum Grinding Wheel | φ100mm × φ32mm × 12mm, 46# grit, used for grinding. |

| Diamond Dresser | Mounted on the mandrel to form the concave arc on the grinding wheel. |

| Mandrel | Clamps the spline shaft and mounts between the grinder’s centers. |

| Positioning Seat | Houses the spring and positioning shaft for indexing. |

| Spring | Resets the positioning shaft after indexing. |

| Base Plate | Z-shaped plate fixed to the grinder’s worktable via T-slot bolts. |

| T-slot Bolt Assembly | Secures the base plate to the worktable. |

The fixture is mounted on the grinder’s worktable using T-slot bolts, allowing for easy installation and removal. This design ensures that the grinder can be restored to its original function for tool sharpening when not used for spline grinding.

Grinding Process Steps

The grinding process for the spline minor diameter consists of three main steps, each critical to achieving the required precision:

Step 1: Spline Shaft Clamping

The spline shaft is clamped onto a mandrel, which is then mounted between the two centers of the tool grinder. This setup ensures stable and accurate positioning of the workpiece during grinding. The mandrel is designed to accommodate the φ40mm centering hole of the spline shaft, providing a reliable datum for machining.

Step 2: Grinding Wheel Dressing

A white corundum grinding wheel (φ100mm × φ32mm × 12mm, 46# grit) is mounted on the grinder’s spindle. A diamond dresser is attached to the mandrel holding the spline shaft. The dresser’s height is set using a height gauge to match the required minor diameter (φ90mm). By rotating the mandrel, the diamond dresser forms a concave arc on the grinding wheel that corresponds to the spline’s minor diameter. This step ensures that the grinding wheel’s profile accurately matches the workpiece’s geometry.

Step 3: Spline Shaft Indexing and Grinding

The fixture’s indexing mechanism relies on the spline shaft’s inherent equal divisions. A Z-shaped base plate is fixed to the grinder’s worktable, supporting a positioning seat with a spring-loaded positioning shaft. To index the spline shaft, the operator pulls the adjusting bolt to disengage the positioning shaft, rotates the spline shaft to the next position, and releases the bolt to lock the shaft in place. The positioning shaft limits circumferential movement, ensuring accurate indexing. The grinder’s axial feed is then used to grind one segment of the minor diameter. This process is repeated for each spline segment until the entire minor diameter is machined.

Implementation and Results

The fixture and process were implemented successfully, allowing the company to transition from outsourced to in-house production of the spline shaft. Over two years, the setup was used to machine approximately 500–600 spline shafts. The fixture’s design, with its T-slot mounting, enabled quick setup and removal, maintaining the grinder’s versatility for other tasks. The process consistently met the design tolerances, including the φ90mm minor diameter and 0.03mm symmetry requirement, while ensuring stable quality across batches.

The in-house approach eliminated dependency on subcontractors, improving quality control and delivery reliability. The use of existing equipment avoided the high capital expenditure associated with purchasing a dedicated spline grinder, making the solution cost-effective for small-batch production.

Conclusion

By leveraging an existing MQ6025A tool grinder and designing a custom fixture, the company achieved precise grinding of rectangular spline minor diameters without additional equipment investment. The process, which includes turning, milling, quenching, and grinding steps, ensures that the spline shaft meets stringent design requirements. The fixture’s modular design and ease of use demonstrate a practical approach to small-batch manufacturing, offering a reliable and repeatable solution for similar applications. This method underscores the value of innovative process design in overcoming equipment limitations while maintaining high standards of quality and efficiency.