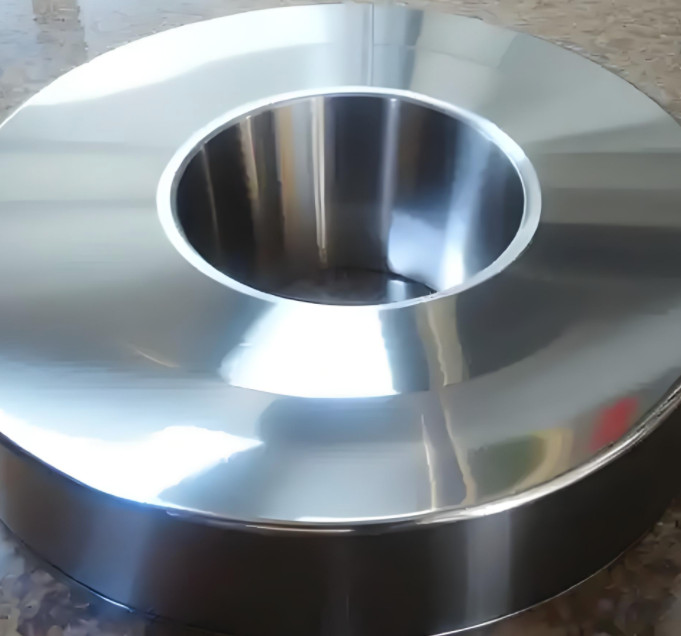

Stainless steel impellers are critical components in industries such as aerospace, automotive, and pump manufacturing, where precision, durability, and corrosion resistance are paramount. Achieving the required surface finish and dimensional accuracy involves surface treatment processes like grinding and polishing. This article provides a detailed comparison of grinding and polishing in the context of stainless steel impeller manufacturing, focusing on process mechanics, precision outcomes, and specific parameters. The goal is to offer a clear, technical understanding to guide manufacturers in selecting the appropriate method for their application.

Overview of Grinding and Polishing

Grinding and polishing are abrasive machining processes used to refine the surface of stainless steel impellers. Each process serves a distinct purpose in achieving the desired surface quality and dimensional precision, with specific tools, abrasives, and techniques tailored to the material properties of stainless steel.

Grinding is a material removal process that uses coarse abrasives to eliminate surface irregularities, machining marks, and excess material. It is typically the first step in surface treatment, preparing the impeller for subsequent finishing processes. Grinding ensures dimensional accuracy and a relatively smooth surface as a foundation for further refinement.

Polishing is a finer surface treatment process that enhances surface smoothness and gloss, often achieving a mirror-like finish. It involves the use of finer abrasives and polishing compounds to remove micro-imperfections, improving both aesthetic appeal and functional properties like corrosion resistance and fluid dynamics.

Both processes are critical in impeller manufacturing, where tight tolerances and surface quality directly impact performance, such as flow efficiency and cavitation resistance. The choice between grinding and polishing, or their combined use, depends on the impeller’s design specifications and application requirements.

Grinding Process for Stainless Steel Impellers

Grinding is a robust process designed to achieve dimensional accuracy and remove surface defects from stainless steel impellers. It is particularly suited for handling the material’s toughness and work-hardening tendencies.

Process Mechanics: Grinding employs abrasive wheels or belts, typically made of materials like aluminum oxide, silicon carbide, or zirconia, to remove material through physical friction. The process is often performed using CNC machines or precision grinders, ensuring consistent material removal across complex impeller geometries. For impellers, grinding is used to refine vane surfaces, hub diameters, and other critical features to meet tight tolerances.

Key Parameters:

- Wheel Grit Size: Typically ranges from 36 to 120 grit for initial grinding, with finer grits (e.g., 180–320) used for subsequent passes to reduce surface roughness.

- Wheel Speed: Ranges from 1,500 to 3,000 RPM, depending on the grinder type and material hardness (e.g., 304 or 316 stainless steel).

- Feed Rate: Controlled at 0.01–0.05 mm/pass to minimize heat generation and work hardening.

- Coolant Usage: Water-based coolants are applied at flow rates of 10–20 L/min to dissipate heat and prevent thermal damage.

- Surface Roughness (Ra): Achieves Ra values of 0.8–3.2 µm, suitable for preparing surfaces for polishing.

Applications in Impeller Manufacturing: Grinding is used to shape impeller vanes, remove casting imperfections (e.g., silica sol residues from investment casting), and achieve dimensional tolerances as tight as ±0.01 mm. It is essential for impellers requiring high structural integrity, such as those in centrifugal pumps or aerospace turbines.

Technical Considerations: Stainless steel’s tendency to work-harden requires careful control of grinding parameters to avoid excessive tool wear or surface deformation. Regular dressing of grinding wheels (every 10–20 passes) maintains abrasive sharpness and consistency. Additionally, coolant application is critical to prevent microstructural changes due to heat, which can compromise corrosion resistance.

Polishing Process for Stainless Steel Impellers

Polishing refines the surface of stainless steel impellers to achieve a smooth, glossy finish, enhancing both functional and aesthetic properties. It is typically performed after grinding to meet stringent surface quality requirements.

Process Mechanics: Polishing uses finer abrasives, such as diamond slurries, aluminum oxide, or colloidal silica, applied via polishing cloths, pads, or wheels. The process may involve manual, automated (e.g., robotic polishing), or vibratory methods, depending on the impeller’s complexity. Polishing removes micro-scratches and irregularities, creating a uniform surface with minimal roughness.

Key Parameters:

- Abrasive Size: Ranges from 1 µm to 0.02 µm (e.g., colloidal silica for vibratory polishing).

- Polishing Speed: Typically 500–1,500 RPM for rotary polishing or 50–100 Hz for vibratory polishing.

- Pressure: Light pressure of 0.1–0.5 MPa to avoid surface deformation.

- Polishing Time: 10–30 minutes per stage, depending on the desired finish and impeller size.

- Surface Roughness (Ra): Achieves Ra values of 0.05–0.2 µm, suitable for mirror-like finishes.

Applications in Impeller Manufacturing: Polishing is critical for impellers in applications requiring low friction, high corrosion resistance, or hygienic surfaces, such as in food processing or medical pumps. For example, a polished impeller with Ra ≤ 0.2 µm improves fluid flow efficiency and reduces cavitation in centrifugal pumps.

Technical Considerations: Polishing requires a clean environment to prevent contamination from dust or debris, which can introduce scratches. For complex impeller geometries, robotic or vibratory polishing ensures uniform coverage of intricate vane surfaces. The choice of polishing compound (e.g., MasterMet 2 colloidal silica) is critical to prevent crystallization and ensure consistent results.

Precision Comparison: Grinding vs. Polishing

The precision of grinding and polishing is evaluated based on dimensional accuracy, surface roughness, and functional outcomes. The following table compares key metrics for both processes in stainless steel impeller manufacturing:

| Parameter | Grinding | Polishing |

|---|---|---|

| Purpose | Material removal, dimensional accuracy | Surface refinement, aesthetic enhancement |

| Surface Roughness (Ra) | 0.8–3.2 µm | 0.05–0.2 µm |

| Tolerance | ±0.01–0.05 mm | ±0.005–0.02 mm |

| Abrasive Size | 36–320 grit | 1–0.02 µm |

| Processing Time | 5–20 min/part | 10–30 min/part |

| Equipment | CNC grinders, abrasive wheels | Polishing wheels, vibratory polishers |

| Applications | Shaping vanes, removing casting defects | Mirror finishes, corrosion resistance |

Dimensional Accuracy: Grinding excels in achieving tight tolerances (±0.01 mm), making it ideal for shaping impeller features like vane thickness or hub diameter. Polishing, while capable of maintaining tolerances (±0.005 mm in some cases), focuses on surface refinement rather than significant material removal.

Surface Roughness: Polishing achieves significantly lower Ra values (0.05–0.2 µm) compared to grinding (0.8–3.2 µm), making it essential for applications requiring high smoothness, such as reducing friction in fluid flow or enhancing corrosion resistance.

Functional Outcomes: Grinding ensures structural integrity and prepares the surface for polishing, while polishing enhances performance characteristics like cavitation resistance and hygiene. For example, a polished impeller with Ra 0.1 µm can improve fuel atomization efficiency by up to 12% in aerospace applications.

Process Integration and Sequencing

In most impeller manufacturing workflows, grinding and polishing are sequential processes. Grinding is performed first to establish dimensional accuracy and remove casting or machining imperfections. Polishing follows to achieve the desired surface finish, particularly for impellers requiring high gloss or low friction.

Sequential Workflow:

- Initial Grinding: Use coarse abrasives (36–80 grit) to remove casting residues and shape vane profiles (Ra 3.2 µm, tolerance ±0.05 mm).

- Fine Grinding: Transition to finer abrasives (180–320 grit) to reduce surface roughness to Ra 0.8–1.6 µm and achieve tolerances of ±0.01 mm.

- Coarse Polishing: Apply 3–6 µm diamond abrasives to further refine the surface to Ra 0.4–0.8 µm.

- Final Polishing: Use 0.02–1 µm colloidal silica or diamond slurries for a mirror finish (Ra 0.05–0.2 µm).

Integration Considerations: The transition from grinding to polishing requires thorough cleaning to remove abrasive particles, preventing cross-contamination. For example, ultrasonic cleaning with distilled water ensures no residual grit compromises the polishing stage. Additionally, the choice of polishing method (e.g., vibratory for complex geometries) depends on the impeller’s design and material (e.g., 316L stainless steel for medical applications).

Material-Specific Considerations for Stainless Steel

Stainless steel’s properties, such as corrosion resistance and work hardening, influence the choice of grinding and polishing parameters. Common grades like 304, 316, and 17-4 PH have varying hardness and ductility, requiring tailored approaches.

Material Properties:

| Stainless Steel Grade | Hardness (HRC) | Ductility | Grinding Considerations | Polishing Considerations |

|---|---|---|---|---|

| 304 | 20–25 | High | Use lower feed rates to prevent work hardening | Fine abrasives (1 µm) for mirror finish |

| 316 | 25–30 | Moderate | Coolant critical to avoid thermal damage | Vibratory polishing for uniform finish |

| 17-4 PH | 35–40 | Low | Sharp wheels to minimize tool wear | Electropolishing for oxide removal |

Work Hardening: Stainless steel’s tendency to harden during grinding can increase tool wear and surface stress. Using sharp abrasives and controlled feed rates mitigates this issue.

Corrosion Resistance: Polishing enhances the passive oxide layer on stainless steel, improving corrosion resistance. For example, electropolishing 316L stainless steel can increase pitting resistance potential by over 300 mV.

Conclusion

Grinding and polishing are complementary processes in stainless steel impeller manufacturing, each contributing to precision and performance. Grinding ensures dimensional accuracy and prepares the surface, while polishing achieves superior smoothness and functional enhancements. By understanding the mechanics, parameters, and material-specific considerations, manufacturers can optimize their processes to meet stringent requirements. The sequential integration of grinding and polishing, tailored to the impeller’s design and material, ensures high-quality outcomes for applications ranging from pumps to aerospace turbines.