CNC milling is a cornerstone of modern manufacturing, enabling the production of high-precision parts with complex geometries. This guide provides a detailed overview of CNC milling, including its processes, key components, material selection, and design considerations. It is structured to offer clear, professional insights for engineers, manufacturers, and enthusiasts seeking to understand or optimize CNC milling for precision parts.

What Is CNC Milling

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece, shaping it into a precise component. Unlike additive manufacturing, such as 3D printing, CNC milling removes material using rotating cutting tools guided by G-code instructions. This process is widely used in industries like aerospace, automotive, medical, and electronics due to its ability to achieve tight tolerances and high repeatability.

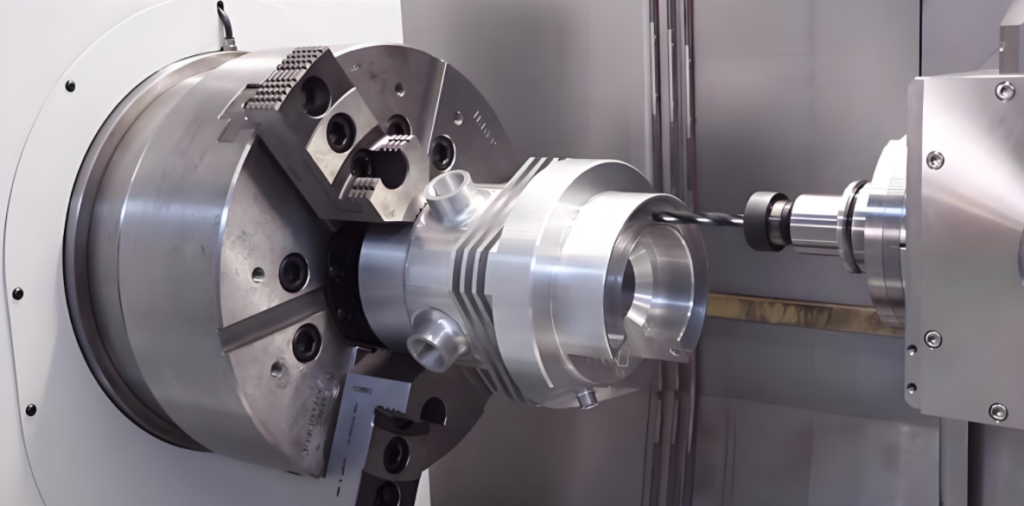

The milling process involves several stages: design, programming, machine setup, machining, and finishing. Each stage requires careful consideration to ensure precision and efficiency. CNC milling machines can operate on 3, 4, or 5 axes, with more axes allowing for greater flexibility in creating complex shapes.

Key Components of a CNC Milling Machine

A CNC milling machine comprises several critical components that work together to achieve precise results. Understanding these components is essential for optimizing performance and troubleshooting issues.

| Component | Function | Key Specifications |

|---|---|---|

| Machine Control Unit (MCU) | Interprets G-code and controls machine movements | Processes instructions at speeds up to 1,000 commands/second |

| Spindle | Holds and rotates the cutting tool | Speed range: 1,000–24,000 RPM; Power: 5–30 kW |

| Column and Base | Provides structural stability | Materials: Cast iron, epoxy-granite; Vibration damping: <0.01 mm |

| Driving System | Moves tools along X, Y, Z axes | Servo motors: Torque up to 20 Nm; Stepper motors: 0.01 mm/step |

| Tool Holder | Secures cutting tools in the spindle | Types: BT, CAT, HSK; Runout: <0.005 mm |

The MCU acts as the brain, translating G-code into motor signals for precise tool movement. The spindle, typically operating at high speeds, ensures efficient material removal. The column and base minimize vibrations, maintaining accuracy during high-speed operations. The driving system, powered by servo or stepper motors, controls the X (side-to-side), Y (front-to-back), and Z (vertical) axes, with 5-axis machines adding rotational A and B axes for complex geometries. Tool holders ensure secure and precise tool positioning, with runout tolerances as low as 0.005 mm.

CNC Milling Process

The CNC milling process follows a structured workflow to transform a digital design into a physical part. Below is a step-by-step breakdown:

- Design Phase: Engineers create a 3D model using CAD software (e.g., AutoCAD, SolidWorks). The model includes dimensions, tolerances, and features.

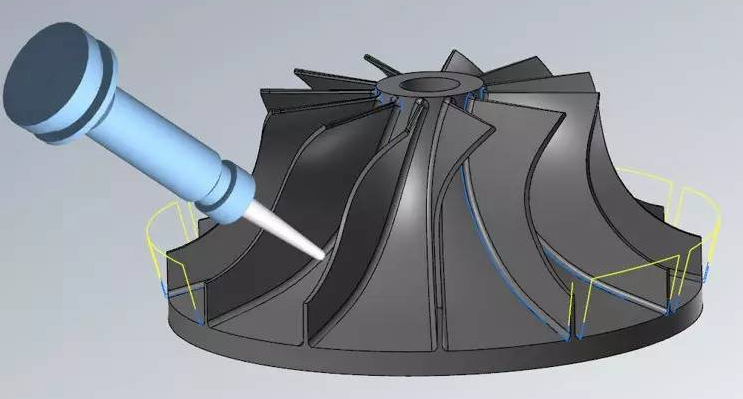

- Programming: CAM software converts the CAD model into G-code, specifying tool paths, speeds, and feed rates.

- Machine Setup: The workpiece is secured on the machine bed or pallet, and appropriate cutting tools are loaded into the spindle.

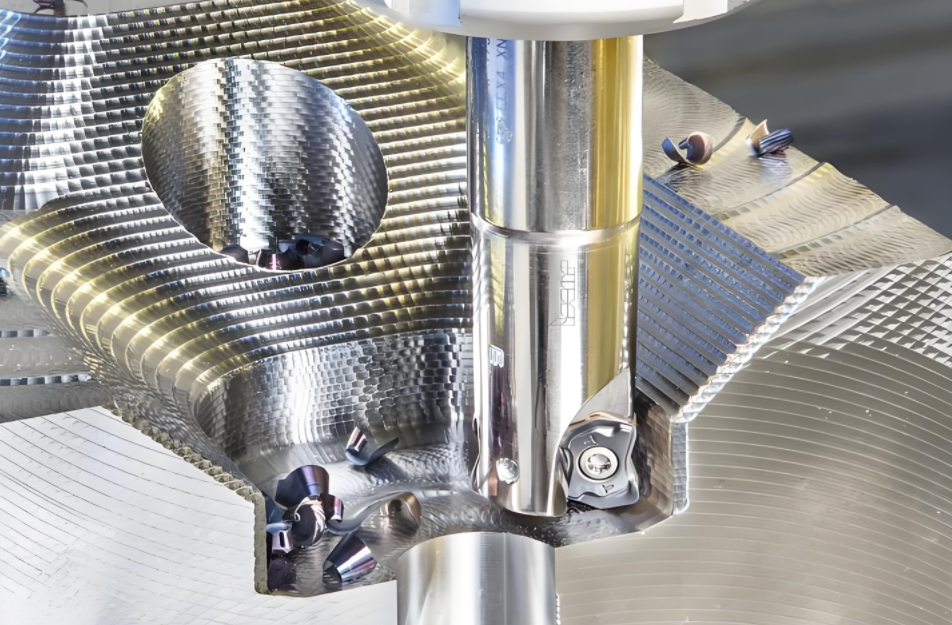

- Machining: The CNC machine executes the G-code, moving the cutting tool to remove material with tolerances as tight as ±0.0002 inches (±0.005 mm).

- Finishing: Post-processing steps like deburring, polishing, or coating enhance surface finish and functionality.

Each step requires precise calibration to avoid errors, such as tool deflection or misalignment, which can compromise part quality.

Material Selection for CNC Milling

Material choice significantly impacts part performance, machinability, and cost. Common materials include metals, plastics, and composites, each with specific properties suited for different applications.

| Material | Properties | Applications | Machinability |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, high strength-to-weight ratio | Aerospace, automotive, electronics | Excellent; feed rates up to 1,000 mm/min |

| Stainless Steel | High strength, corrosion-resistant | Medical, defense, industrial | Moderate; feed rates 200–500 mm/min |

| Titanium | High strength, low density, heat-resistant | Aerospace, medical implants | Challenging; feed rates 50–150 mm/min |

| ABS Plastic | Impact-resistant, lightweight | Prototyping, consumer goods | Excellent; feed rates up to 1,200 mm/min |

Aluminum is favored for its machinability and versatility, making it ideal for complex designs. Stainless steel offers durability but requires slower feed rates due to its hardness. Titanium, while strong and lightweight, is difficult to machine, demanding specialized tools and lower speeds. Plastics like ABS are easy to machine and cost-effective for prototypes but may lack the strength for structural components.

Design Considerations for CNC Milling

Designing parts for CNC milling requires adherence to specific guidelines to ensure manufacturability and cost-efficiency. Key considerations include:

- Tolerances: Specify tolerances realistically, as tighter tolerances (e.g., ±0.0002 inches) increase costs. Standard tolerances are typically ±0.005 inches (±0.127 mm).

- Internal Corners: Due to cylindrical cutting tools, internal corners have a radius. Minimum radius: 0.5 mm for end mills.

- Hole Design: Use standard drill bit sizes for holes under 20 mm. Maximum hole depth: 4–10 times the diameter; deeper holes require specialized tools.

- Cavity Depth: Limit cavity depth to 3–4 times the tool diameter to avoid deflection. Deep cavities (>6 times diameter) need specialized tooling.

- Text and Engraving: Use font sizes ≥20 points and engraving depths of 0.5–1 mm for clarity and machinability.

- Material Selection: Match material properties to application needs, considering machinability and environmental factors.

Aligning features with the X, Y, or Z axes simplifies machining, while 5-axis machines can handle non-aligned features but increase setup complexity. Avoiding overly thin walls (minimum 0.5 mm for metals, 1 mm for plastics) prevents vibration and breakage.

Advantages of CNC Milling

CNC milling offers several benefits that make it a preferred choice for precision manufacturing:

- Precision: Achieves tolerances as tight as ±0.0001 inches (±0.00254 mm) for critical applications.

- Versatility: Handles a wide range of materials and geometries, from simple slots to complex 5-axis contours.

- Repeatability: Produces identical parts consistently, ideal for high-volume production.

- Efficiency: Automation reduces labor costs and enables 24/7 operation with minimal human intervention.

- Scalability: Suitable for prototyping and large-scale production, with setup times as low as 1–2 hours for simple parts.

These advantages make CNC milling indispensable for industries requiring high accuracy and consistency, such as aerospace (turbine blades) and medical (surgical instruments).

Applications of CNC Milling

CNC milling is used across various industries to produce precision parts. Common applications include:

- Aerospace: Turbine blades, landing gear components, and structural parts with tolerances of ±0.01 mm.

- Automotive: Engine blocks, transmission gears, and suspension components requiring high durability.

- Medical: Surgical tools, prosthetics, and implants with biocompatible materials like titanium.

- Electronics: Circuit board enclosures, heat sinks, and connectors with intricate designs.

- Defense: Weapon components and military vehicle parts requiring tight tolerances and reliability.

The ability to produce complex geometries with high precision makes CNC milling critical for mission-critical applications.

Future Trends in CNC Milling

CNC milling continues to evolve with technological advancements, enhancing its capabilities and efficiency:

- AI Integration: Machine learning optimizes tool paths, reducing machining time by up to 20% and predicting maintenance needs.

- Hybrid Manufacturing: Combining CNC milling with additive manufacturing for complex parts with reduced material waste.

- Sustainability: Dry machining and eco-friendly lubricants reduce environmental impact by minimizing coolant use.

- Smart Tools: Sensors monitor tool condition, vibrations, and temperature, reducing downtime by up to 20%.

These trends indicate a shift toward smarter, more sustainable, and efficient CNC milling processes, further expanding its applications.

Conclusion

CNC milling is a versatile and precise manufacturing process that transforms raw materials into high-quality parts for various industries. By understanding its components, processes, material considerations, and design guidelines, manufacturers can optimize production for accuracy, efficiency, and cost-effectiveness. As technology advances, CNC milling will continue to play a pivotal role in modern manufacturing, driven by innovations like AI and hybrid techniques.