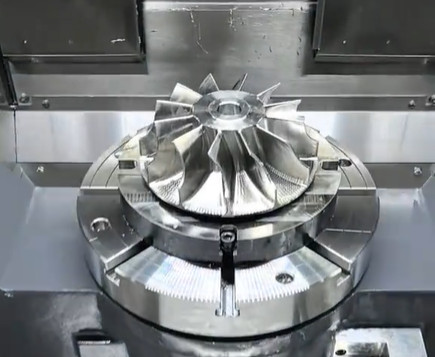

Titanium alloy impellers are critical components in aerospace, marine, and industrial applications due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme conditions. Achieving optimal mechanical properties requires precise heat treatment and strength optimization processes. This article provides a comprehensive, technical overview of these processes, focusing on detailed parameters, microstructure transformations, and their impact on impeller performance. The content is structured to offer practical insights for engineers and researchers, emphasizing experience, reliability, and professionalism.

Overview of Titanium Alloy Impellers

Titanium alloys, particularly α+β alloys like Ti-6Al-4V, are widely used for impellers due to their excellent mechanical properties. These components operate under high rotational speeds, cyclic loading, and aggressive environments, necessitating superior strength, fatigue resistance, and toughness. Heat treatment plays a pivotal role in tailoring the microstructure to meet these demands, while strength optimization ensures the impeller can endure operational stresses without failure.

The primary goal of heat treatment is to control phase transformations between the α (hexagonal close-packed) and β (body-centered cubic) phases, which directly influence hardness, tensile strength, and ductility. Strength optimization involves balancing these properties to achieve a microstructure that maximizes performance under specific service conditions.

Heat Treatment Processes for Titanium Alloy Impellers

Heat treatment of titanium alloy impellers typically involves stress relief annealing, solution treatment, and aging. Each process is designed to address specific microstructural and mechanical requirements.

Stress Relief Annealing

Stress relief annealing eliminates residual stresses introduced during manufacturing processes such as forging, machining, or welding. For titanium alloy impellers, this process is conducted at temperatures between 480°C and 650°C for 1 to 4 hours, followed by air cooling. The annealing temperature is selected below the recrystallization point to prevent grain growth, which could compromise mechanical properties.

This process enhances dimensional stability and reduces the risk of distortion during subsequent treatments. For Ti-6Al-4V, a typical parameter is 600°C for 2 hours, ensuring stress relaxation without altering the as-forged microstructure.

Solution Treatment

Solution treatment involves heating the impeller to a temperature within or slightly below the α+β phase field, typically 900°C to 950°C for Ti-6Al-4V, to dissolve alloying elements into the β phase. The material is held at this temperature for 30 minutes to 1 hour, followed by rapid cooling (e.g., water quenching) to room temperature.

Water quenching results in a martensitic transformation, forming a metastable α′ phase or retained β phase, depending on the cooling rate. This phase is characterized by high hardness but low ductility. For impellers, solution treatment at 925°C for 30 minutes, followed by water quenching, achieves a hardness of approximately 35 HRC due to the formation of fine α′ martensite.

| Parameter | Value | Effect |

|---|---|---|

| Temperature | 900–950°C | Dissolves alloying elements into β phase |

| Holding Time | 30–60 min | Ensures homogeneous phase distribution |

| Cooling Method | Water Quenching | Forms metastable α′ martensite |

| Hardness | ~35 HRC | Increases due to martensitic transformation |

Aging Treatment

Aging treatment follows solution treatment to precipitate secondary α (αs) phases within the retained β or martensitic matrix, enhancing strength and toughness. For Ti-6Al-4V impellers, aging is typically performed at 500°C to 600°C for 4 to 8 hours, followed by air cooling. This process transforms the metastable phases into a stable α+β microstructure, improving tensile strength and fatigue resistance.

Aging at 600°C for 4 hours results in an ultimate tensile strength of approximately 1028 MPa and an elongation of 10–14%, striking a balance between strength and ductility. The precipitation of fine αs platelets within the β matrix is responsible for this enhancement.

Microstructure Transformations During Heat Treatment

The mechanical properties of titanium alloy impellers are directly linked to their microstructure, which evolves significantly during heat treatment. Understanding these transformations is critical for optimizing impeller performance.

Initial Microstructure

As-forged Ti-6Al-4V impellers typically exhibit a bimodal microstructure consisting of equiaxed primary α (αp) grains and transformed β regions containing lamellar α+β phases. This structure provides a baseline for subsequent heat treatments, offering moderate strength and ductility.

Changes During Solution Treatment

During solution treatment at 925°C, the α phase partially transforms into β, and alloying elements such as vanadium and aluminum diffuse into the β phase. Rapid cooling via water quenching suppresses the reformation of equilibrium α, resulting in a microstructure dominated by acicular α′ martensite or retained β. The α′ phase is needle-like and contributes to high hardness but increases brittleness, necessitating aging to restore ductility.

Changes During Aging

Aging at 600°C induces the decomposition of α′ martensite and retained β into a fine dispersion of secondary α (αs) platelets within a β matrix. This α+β microstructure enhances strength through precipitation hardening while improving toughness and fatigue resistance. The size and distribution of αs platelets are critical; finer platelets (achieved at lower aging temperatures) increase strength, while coarser platelets (higher temperatures) improve ductility.

For impellers, a lamellar α+β microstructure with fine αs platelets is preferred, as it provides an optimal combination of tensile strength (1000–1100 MPa) and elongation (10–15%).

Strength Optimization Strategies

Strength optimization of titanium alloy impellers involves tailoring heat treatment parameters to achieve a microstructure that maximizes mechanical properties under operational conditions. The following strategies are commonly employed.

Balancing Strength and Ductility

Impellers require high tensile strength to withstand centrifugal forces and sufficient ductility to resist crack propagation under cyclic loading. Solution treatment followed by aging at 600°C achieves this balance, producing a tensile strength of 1028 MPa and elongation of 14%. Adjusting the aging temperature (e.g., 550°C for higher strength or 650°C for better ductility) allows fine-tuning of properties.

Enhancing Fatigue Resistance

Fatigue resistance is critical for impellers subjected to cyclic stresses. A fine, homogeneous α+β microstructure with minimal porosity reduces stress concentrations and crack initiation sites. Solution treatment at 900°C with controlled cooling rates (e.g., air cooling instead of water quenching) can minimize residual stresses, while aging at 600°C refines the microstructure for improved fatigue life.

Controlling Residual Stresses

Residual stresses from manufacturing or rapid cooling during heat treatment can reduce impeller lifespan. Stress relief annealing at 600°C before solution treatment mitigates these stresses, improving dimensional stability and fatigue performance. Vacuum or inert gas environments during heat treatment prevent surface oxidation, which could otherwise act as a stress riser.

Mechanical Property Enhancements

The combined effect of heat treatment and strength optimization significantly enhances the mechanical properties of titanium alloy impellers. The following table summarizes typical improvements for Ti-6Al-4V impellers after optimized heat treatment.

| Property | As-Forged | After Solution + Aging |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 900–950 | 1000–1100 |

| Yield Strength (MPa) | 830–880 | 900–950 |

| Elongation (%) | 8–12 | 10–15 |

| Hardness (HRC) | 30–32 | 34–36 |

| Fatigue Strength (MPa) | 400–450 | 500–550 |

Practical Considerations for Implementation

Implementing heat treatment and strength optimization for titanium alloy impellers requires precise control of process parameters and environmental conditions. Key considerations include:

- Furnace Calibration: Ensure uniform temperature distribution (±5°C) to prevent microstructural inconsistencies.

- Cooling Rate Control: Use calibrated quenching media to achieve consistent cooling rates, avoiding excessive residual stresses.

- Protective Atmosphere: Conduct heat treatments in vacuum or argon to prevent oxygen contamination, which can embrittle the surface.

- Quality Assurance: Perform non-destructive testing (e.g., X-ray diffraction, ultrasonic inspection) to verify microstructure and detect defects.

These measures ensure repeatability and reliability, critical for high-performance impellers in demanding applications.

Conclusion

Heat treatment and strength optimization are essential for enhancing the performance of titanium alloy impellers. Through stress relief annealing, solution treatment, and aging, the microstructure can be tailored to achieve a balance of strength, ductility, and fatigue resistance. Precise control of parameters—such as solution treatment at 925°C for 30 minutes, water quenching, and aging at 600°C for 4 hours—results in significant mechanical property improvements, including tensile strengths of 1000–1100 MPa and elongations of 10–15%. By understanding microstructure transformations and implementing robust process controls, manufacturers can produce reliable, high-performance impellers for critical applications.