Impellers and propellers are rotating components used to manage fluid dynamics, each with distinct roles in various systems. While both leverage rotational motion to interact with fluids, their designs, functions, and applications differ significantly. This article provides a clear, technical comparison of their definitions, operational functions, and practical uses, supported by structured data for clarity.

Definitions

What Is An Impeller

An impeller is a rotating component, typically enclosed within a housing, designed to transfer energy to a fluid, increasing its pressure and flow. It is commonly used in centrifugal pumps, compressors, and mixers, where it accelerates fluid outward from its center, creating a pressure differential that drives fluid movement.

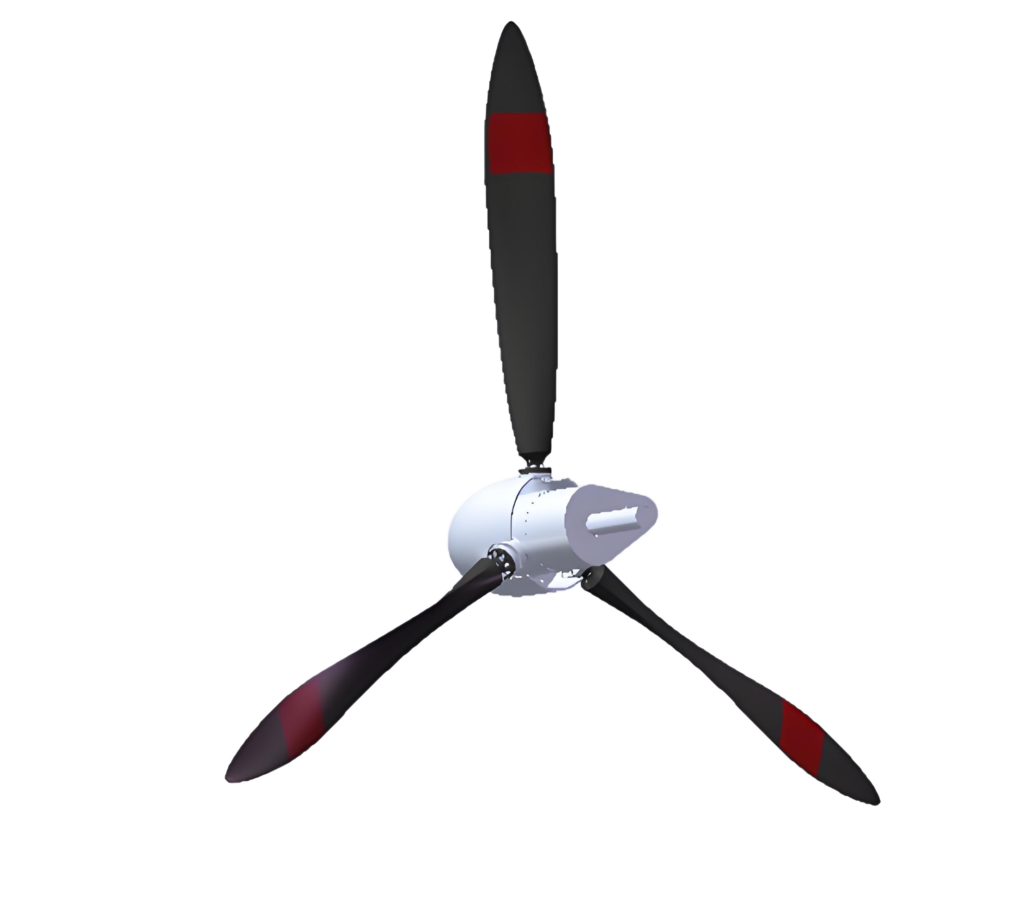

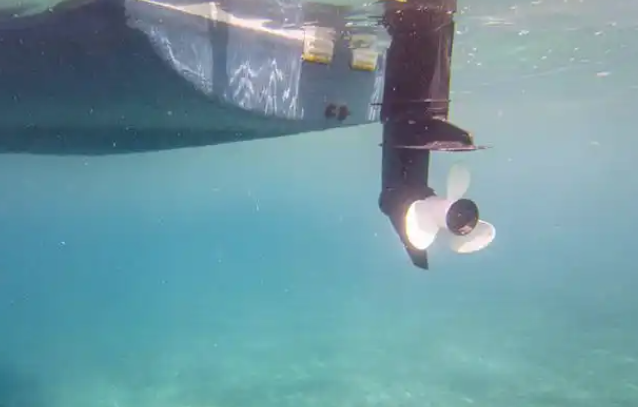

What Is A Propeller

A propeller is a fan-like device with angled blades that rotates to generate linear thrust, propelling a vehicle through a fluid medium such as air or water. It operates in an open environment, converting rotational energy into directional motion, primarily used in marine and aviation propulsion systems.

Functions

임펠러 and propellers serve different purposes in fluid dynamics, determined by their operational environments and design objectives. The table below outlines their primary functions and technical parameters.

| 측면 | Impeller | Propeller |

|---|---|---|

| Primary Function | Increases fluid pressure and flow in enclosed systems | Generates linear thrust for propulsion in open environments |

| Mechanism | Centrifugal force accelerates fluid radially, creating high pressure | Blade angle creates pressure difference, producing thrust (Bernoulli’s principle/Newton’s third law) |

| Fluid Interaction | Handles high-viscosity fluids; axial inflow, radial outflow | Optimized for low-viscosity fluids (air, water); axial flow |

| 회전 속도 | Typically 1,000–10,000 RPM, depending on pump design | Typically 1,000–5,000 RPM for marine; 2,000–10,000 RPM for aviation |

| Efficiency Metric | Head (pressure) and flow rate | Thrust-to-power ratio |

| Environment | Enclosed (e.g., pump casing, compressor) | Open (e.g., water, air) |

애플리케이션

Impellers and propellers are applied in diverse industries based on their functional capabilities. The table below summarizes their key applications across various sectors.

| 산업 | Impeller Applications | Propeller Applications |

|---|---|---|

| 해양 | Water jet propulsion, engine cooling pumps, bilge pumps | Boat and submarine propulsion, outboard motors |

| Aviation | Jet engine compressors, aircraft HVAC systems | Airplane and drone propulsion, helicopter rotors |

| 산업 | Centrifugal pumps for chemical processing, wastewater treatment, oil refining | Industrial fans, ventilation systems, wind turbine blades |

| Household | Washing machine agitators, aquarium pumps, HVAC circulation | Ceiling fans, small recreational drones |

| 에너지 | Hydropower turbine impellers, biofuel mixing systems | Wind turbine propulsion, tidal energy systems |

Technical Considerations

Impeller Characteristics

- Design: Curved vanes, often enclosed or semi-enclosed, with configurations like radial, axial, or mixed-flow.

- Materials: Stainless steel, bronze, or plastics for corrosion resistance; rubber for abrasive fluids.

- 장점: High efficiency in pressure generation, suitable for dense fluids, customizable for specific applications.

- 제한 사항: Susceptible to cavitation, wear from abrasive fluids, and maintenance challenges in enclosed systems.

Propeller Characteristics

- Design: 2–6 blades with pitch angles optimized for thrust; fixed or variable pitch options.

- Materials: Aluminum, stainless steel, or composites for lightweight strength and corrosion resistance.

- 장점: High thrust efficiency, adaptable to varying conditions, easier to maintain in open environments.

- 제한 사항: Noise generation, reduced efficiency at high speeds, potential for blade erosion in harsh conditions.

Recent Developments

Advancements in materials and technology have improved both impellers and propellers. Impellers now use IoT sensors for real-time monitoring of flow and wear, enhancing system reliability. Propellers benefit from variable-pitch mechanisms and computational fluid dynamics (CFD) for optimized blade designs, improving fuel efficiency in marine and aviation applications. Composite materials reduce weight and corrosion, extending service life for both components.

결론

Impellers and propellers are specialized tools for fluid management, with impellers focusing on pressure and flow in enclosed systems and propellers generating thrust for propulsion in open environments. Their distinct designs and functions make them suited to specific applications across marine, aviation, industrial, and household sectors. By understanding their definitions, functions, and applications, engineers and professionals can select the appropriate component for optimal performance.