A vacuum pump is a mechanical device designed to remove gas molecules from a sealed volume, creating a partial or high vacuum. These pumps, including those utilizing impellers, are critical in industries ranging from manufacturing to scientific research. This article provides a comprehensive overview of vacuum pumps, detailing their structure, operational principles, types (with a focus on impeller-based designs), and applications, supported by technical parameters.

Structure of Vacuum Pumps

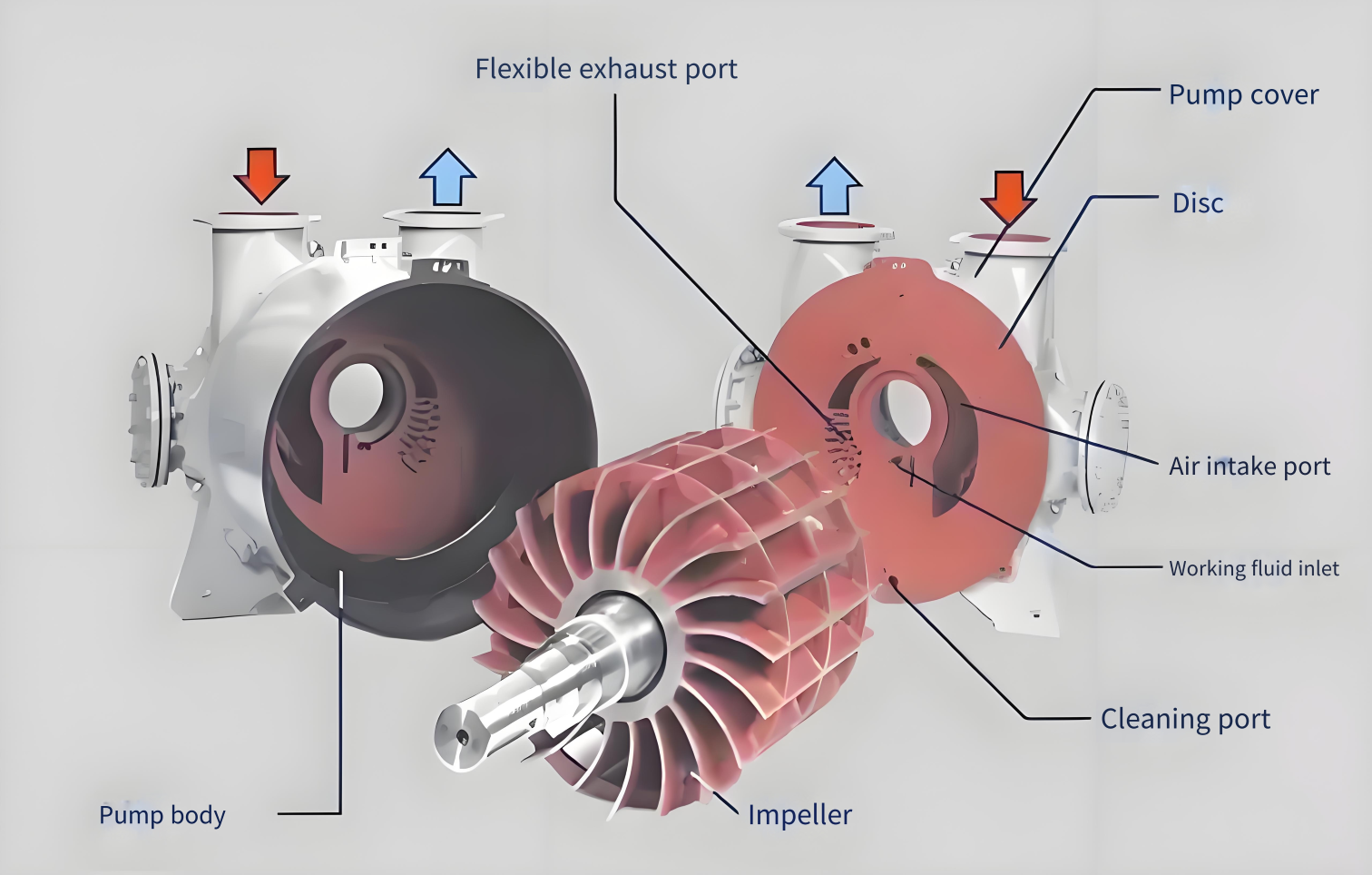

Vacuum pumps vary in design based on their type and application, but most share common structural components. These components, including impellers in certain designs, work together to achieve the desired vacuum level by manipulating gas flow and pressure.

- Inlet Port: The entry point where gas is drawn into the pump from the vacuum chamber.

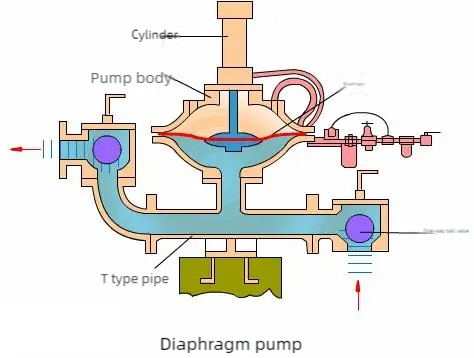

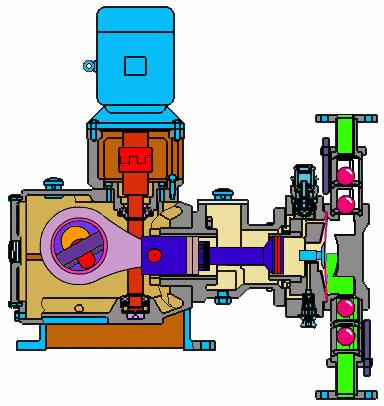

- Pumping Mechanism: The core component, which varies by pump type (e.g., impellers, rotors, diaphragms, or screws), responsible for gas removal. In impeller-based pumps, such as liquid ring pumps, the impeller rotates to create a dynamic seal and move gas.

- Outlet Port: The exit where compressed gas is expelled, often to the atmosphere or another system.

- Sealing System: Ensures airtight operation, using materials like low-vapor-pressure oil, PTFE seals, or liquid (in impeller-based liquid ring pumps) to prevent leaks.

- Motor and Drive System: Powers the pump, typically via electric motors, driving components like impellers or rotors through gears or belts.

- Housing/Chamber: Encloses the pump mechanism, often made of metal for high-vacuum systems to minimize outgassing.

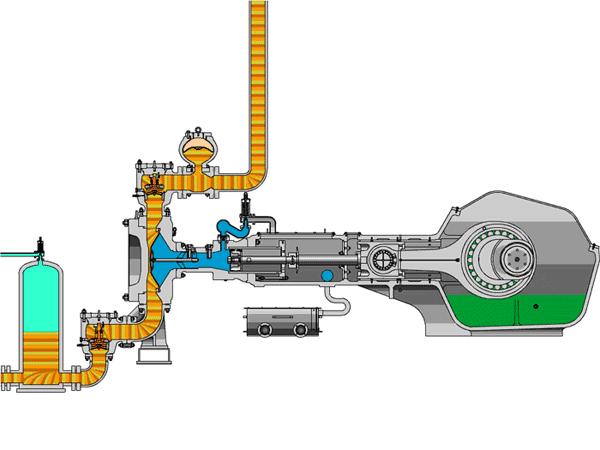

The structural design, including the impeller’s role in certain pumps, is tailored to the operating pressure range, from rough vacuum (760 to 10⁻³ Torr) to ultrahigh vacuum (below 10⁻⁷ Torr). High-vacuum systems use metal chambers with metal gasket seals (e.g., Klein or ISO flanges) to reduce outgassing, while impeller-based pumps like liquid ring pumps often use robust casings to handle liquid and gas interactions.

Function of Vacuum Pumps

Vacuum pumps function by removing gas molecules from a sealed chamber to reduce pressure and create a vacuum. The mechanism, including impeller-driven designs, depends on the pump type, categorized as gas transfer or entrapment pumps.

Gas Transfer Pumps

Gas transfer pumps move gas from the inlet to the outlet via mechanical displacement or momentum transfer.

- Positive Displacement Pumps: These expand a cavity to draw in gas, then compress and expel it. Liquid ring pumps, which use an impeller to rotate a liquid ring that compresses gas, achieve pressures down to 30 Torr with pumping speeds of 25 to 30,000 m³/h. The impeller’s rotation creates a dynamic seal, enabling continuous gas movement.

- Momentum Transfer Pumps: These accelerate gas molecules to create a low-pressure region. Turbomolecular pumps, using high-speed rotors (not impellers), achieve pressures as low as 10⁻⁹ Torr with pumping speeds of 50 to 5,000 l/s.

Entrapment Pumps

Entrapment pumps capture gas molecules on surfaces within the pump, typically through condensation or ionization, and do not typically use impellers.

- Cryopumps: Use cryogenic surfaces (10–20 K) to condense gases, achieving pressures as low as 7.5 x 10⁻¹⁰ Torr with pumping speeds of 1,200 to 4,200 l/s.

- Ion Pumps: Ionize and capture gas molecules on a titanium cathode, suitable for ultrahigh vacuum applications.

Performance metrics include ultimate pressure (lowest achievable pressure), pumping speed (volume of gas removed per unit time), throughput (gas processed over time), and compression ratio (outlet to inlet pressure ratio). For impeller-based pumps, the impeller’s design (e.g., blade angle, material) significantly affects efficiency and pressure range.

Types of Vacuum Pumps

Vacuum pumps are classified by their operating pressure range and mechanism, with impeller-based designs prominent in certain types. The table below summarizes key pump types, including those using 임펠러, with their principles and parameters.

| Pump Type | Operating Principle | Pressure Range (Torr) | Pumping Speed | 애플리케이션 |

|---|---|---|---|---|

| Rotary Vane | Positive displacement; rotating vanes compress gas | 760 to 10⁻³ | 25–30,000 m³/h | Vacuum packaging, HVAC |

| Liquid Ring | Positive displacement; impeller rotates liquid to form a sealing ring | 760 to 30 | 25–30,000 m³/h | Chemical processing, distillation |

| Turbomolecular | Momentum transfer; high-speed rotors | 10⁻³ to 10⁻⁹ | 50–5,000 l/s | Semiconductor manufacturing, research |

| Cryopump | Entrapment; cryogenic condensation | 10⁻³ to 7.5 x 10⁻¹⁰ | 1,200–4,200 l/s | Space simulation, particle accelerators |

| Ion Pump | Entrapment; ionization and capture | 10⁻³ to 10⁻¹¹ | 10–1,000 l/s | Ultrahigh vacuum research |

Applications of Vacuum Pumps

Vacuum pumps, including impeller-based designs, are integral to industries requiring controlled low-pressure environments. Below are key applications, categorized by industry.

Industrial Applications

Impeller-based vacuum pumps, such as liquid ring pumps, are particularly suited for industrial processes due to their robustness and ability to handle wet gases.

- Vacuum Packaging: Removes air to extend shelf life in food and pharmaceutical packaging, often using rotary vane pumps but occasionally impeller-based liquid ring pumps for humid environments.

- Distillation: Liquid ring pumps with impellers lower boiling points for efficient liquid separation in chemical and pharmaceutical industries, handling vapor-heavy processes.

- Degassing: Removes trapped gases from materials like metals and polymers, with impeller-driven liquid ring pumps used for their ability to manage condensable gases.

- Vacuum Furnaces: Used in heat treatment and brazing to prevent oxidation, typically with rotary vane or turbomolecular pumps, though impeller-based pumps are used in specific wet processes.

Scientific and Research Applications

High and ultrahigh vacuum pumps, which rarely use impellers, are critical in research settings requiring precise atmospheric control.

- Semiconductor Manufacturing: Turbomolecular and cryopumps create clean, low-pressure environments for etching and deposition.

- 입자 가속기: Ion pumps maintain ultrahigh vacuums for particle beam stability.

- Space Simulation: Cryopumps simulate near-vacuum conditions for testing satellite components.

기타 애플리케이션

Impeller-based vacuum pumps also serve niche applications, such as:

- Medical Devices: Diaphragm pumps are common, but impeller-based liquid ring pumps are used in systems requiring vapor handling, such as sterilization equipment.

- Environmental Systems: Impeller-driven liquid ring pumps recover solvent vapors in chemical processing, reducing emissions.

Maintenance and Performance Considerations

Regular maintenance ensures vacuum pump reliability, with impeller-based pumps requiring specific attention due to their interaction with liquids. Key considerations include:

- Oil Maintenance: For oil-lubricated pumps like rotary vane, regular oil changes prevent contamination. Impeller-based liquid ring pumps require clean sealing liquid to maintain performance.

- Impeller Maintenance: In liquid ring pumps, impellers must be inspected for wear, corrosion, or imbalance, as these affect sealing efficiency and vacuum performance.

- Leakage Rate: A low leakage rate is critical for high vacuum levels. Impeller-based pumps require checks on liquid seals and casing integrity to prevent air ingress.

- Pump-Specific Maintenance: Dry pumps need less maintenance due to no oil, but impeller-based pumps require regular liquid replacement and impeller cleaning to prevent scaling or corrosion.

The table below outlines maintenance requirements for common vacuum pump types, including impeller-based designs.

| Pump Type | Maintenance Needs | Frequency |

|---|---|---|

| Rotary Vane | Oil changes, vane inspection | Every 3–6 months |

| Liquid Ring | Sealing liquid replacement, impeller inspection and cleaning | Every 6–12 months |

| Turbomolecular | Bearing replacement, rotor balancing | Every 1–2 years |

| Cryopump | Regeneration, compressor maintenance | Every 3–6 months |

결론

Vacuum pumps, including impeller-based designs like liquid ring pumps, are vital for creating low-pressure environments across industrial, scientific, and medical applications. Their structure, tailored to specific vacuum levels, and operational principles, such as impeller-driven gas compression, determine their suitability for tasks from distillation to ultrahigh vacuum research. Understanding pump types, performance parameters, and maintenance needs, particularly for impeller maintenance in liquid ring pumps, ensures optimal performance and longevity. By selecting the appropriate pump and maintaining it properly, industries can achieve high efficiency and precision in their processes.