Aluminum alloys are extensively used in impeller manufacturing due to their superior strength-to-weight ratio, corrosion resistance, and machinability. These properties make them ideal for applications in pumps, turbines, and mixers across industries like aerospace, automotive, and wastewater treatment.

알루미늄 합금이란?

Aluminum alloys are materials composed primarily of aluminum combined with alloying elements such as copper, magnesium, silicon, zinc, or nickel to enhance specific properties like strength, corrosion resistance, or thermal stability. These alloys are classified into series (e.g., 2000, 6000, 7000) based on their primary alloying elements, with compositions tailored to meet mechanical and environmental requirements. For impellers, aluminum alloys are favored for their low density (approximately 2.7 g/cm³), high machinability, and ability to be heat-treated or surface-treated to improve durability and performance in demanding applications.

Why Aluminum Alloys Are the Most Used Material for Impellers

Aluminum alloys dominate impeller manufacturing due to a combination of material properties and practical advantages that align with performance and cost requirements. Key reasons include:

- Lightweight Design: With a density of approximately 2.7 g/cm³, aluminum alloys are significantly lighter than steel (7.8 g/cm³) or cast iron (7.2 g/cm³), reducing rotational inertia and improving energy efficiency by up to 5% in high-speed applications like turbochargers.

- 내식성: Alloys like 6061 and 2618 offer excellent resistance to corrosion in environments such as wastewater or marine applications, especially when anodized, reducing maintenance costs.

- Machinability and Versatility: Aluminum alloys are easily machined to tight tolerances (±0.01 mm) and can be cast, forged, or 3D-printed, enabling complex impeller geometries.

- Cost-Effectiveness: Compared to titanium or high-grade stainless steel, aluminum alloys are more economical, with material costs 30–50% lower, making them suitable for large-scale production.

- Thermal Conductivity: High thermal conductivity (150–200 W/m·K) ensures efficient heat dissipation in high-temperature applications, such as automotive cooling systems.

These factors collectively make aluminum alloys the preferred choice for impellers, balancing performance, durability, and economic considerations.

Key Aluminum Alloy Types for Impellers

Several aluminum alloy series are used for impellers, each with distinct compositions and properties. Below is a detailed examination of the most suitable alloys, including 2601 and 2618, and their applications.

2000 Series (Al-Cu Alloys)

The 2000 series, particularly 2024 aluminum, is known for its high strength and fatigue resistance due to copper as the primary alloying element (3.8–4.9% Cu). With a tensile strength of 400–470 MPa, it is suitable for high-stress applications like aerospace impellers. However, its corrosion resistance is moderate unless treated with anodizing or coatings, limiting its use in corrosive environments.

2601 (Al-Cu-Mg Alloy)

The 2601 alloy, a variant of the 2000 series, contains copper (3.5–4.5%), magnesium (1.0–1.5%), and trace elements like iron and silicon. It offers a tensile strength of 420–480 MPa and excellent fatigue resistance, making it suitable for impellers in high-performance pumps. Its enhanced toughness compared to 2024 makes it ideal for applications requiring resistance to cyclic loading, such as in industrial compressors.

2618 (Al-Cu-Mg-Fe-Ni Alloy)

The 2618 alloy, also part of the 2000 series, is designed for high-temperature applications, with a composition of copper (1.9–2.7%), magnesium (1.3–1.8%), and nickel (0.9–1.2%). It has a tensile strength of 400–450 MPa and maintains mechanical properties at temperatures up to 200°C, making it suitable for automotive turbochargers and aerospace impellers operating under thermal stress.

6000 Series (Al-Mg-Si Alloys)

The 6000 series, such as 6061, offers a balance of strength (tensile strength: 240–310 MPa), corrosion resistance, and machinability. Containing magnesium (0.8–1.2%) and silicon (0.4–0.8%), these alloys are heat-treatable and widely used in wastewater treatment and chemical processing impellers due to their resistance to mildly corrosive fluids.

7000 Series (Al-Zn Alloys)

The 7000 series, particularly 7075, provides the highest strength (tensile strength: 500–570 MPa) due to zinc (5.1–6.1%) and magnesium (2.1–2.9%) additions. These alloys are ideal for high-performance impellers in aerospace and automotive applications, though they require protective coatings for corrosive environments.

Other Alloy Series

Beyond the 2000, 6000, and 7000 series, other aluminum alloys like the 5000 series (Al-Mg, e.g., 5083) and 1000 series (near-pure aluminum, e.g., 1100) are occasionally used for impellers. The 5000 series offers excellent corrosion resistance but lower strength (150–300 MPa), suitable for marine applications. The 1000 series, with minimal alloying, provides high corrosion resistance but limited mechanical strength (70–150 MPa), restricting its use to low-stress, non-critical impellers.

Material Properties and Performance Benefits

Aluminum alloys offer distinct advantages for impeller applications. The table below summarizes key properties and their impact on impeller performance.

| 합금 | Density (g/cm³) | 인장 강도(MPa) | 내식성 | Key Benefits |

|---|---|---|---|---|

| 2024 | 2.78 | 400–470 | Moderate (requires coating) | High strength, fatigue resistance |

| 2601 | 2.77 | 420–480 | 보통 | Enhanced toughness, cyclic loading resistance |

| 2618 | 2.76 | 400–450 | 보통 | High-temperature stability |

| 6061 | 2.70 | 240–310 | Good | Balanced strength, corrosion resistance |

| 7075 | 2.81 | 500–570 | Moderate (requires coating) | Superior strength-to-weight ratio |

Manufacturing Processes for Aluminum Alloy Impellers

The production of aluminum alloy impellers involves advanced manufacturing techniques to achieve precise geometries and optimal performance. Below are the primary processes used.

Casting

Casting, including sand casting and die casting, is commonly used for producing complex impeller shapes. Die casting offers high dimensional accuracy (tolerances ±0.1 mm) and is suitable for high-volume production of 6000 series and 2618 impellers. Porosity can be mitigated through vacuum casting or heat treatment (e.g., T6 tempering at 520°C for 8 hours followed by water quenching).

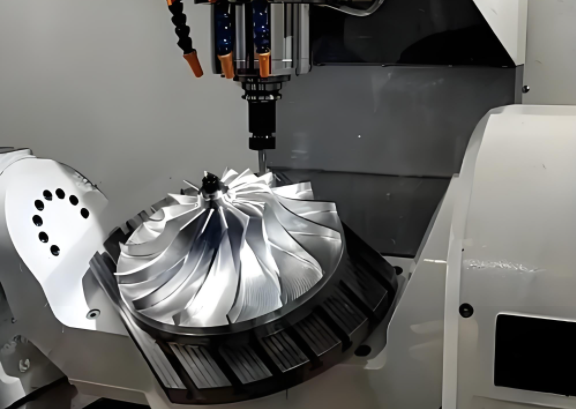

CNC 가공

Computer Numerical Control (CNC) machining is employed for precision impellers, particularly for 2000 (including 2601 and 2618) and 7000 series alloys. It achieves tight tolerances (±0.01 mm) and smooth surface finishes (Ra 0.4–0.8 µm). Five-axis CNC machining ensures uniform blade profiles, minimizing flow disruptions in high-efficiency pumps.

Additive Manufacturing (3D Printing)

Additive manufacturing, such as Selective Laser Melting (SLM), is used for prototyping and producing lightweight impellers with intricate designs. For 7075 and 2618 alloys, SLM achieves density >99.5% with post-processing heat treatment (solution annealing at 480°C for 2 hours), ideal for aerospace impellers with customized designs.

표면 처리

Surface treatments like anodizing and coating enhance aluminum alloy impellers’ durability. Hard anodizing increases surface hardness to 400–600 HV, improving wear resistance in abrasive fluids. For example, 6061 impellers anodized with a 50 µm oxide layer exhibit a 30% increase in lifespan in wastewater applications. Chromate coatings further enhance corrosion resistance for 2601 and 2618 alloys in saline environments.

Performance Impacts of Aluminum Alloy Impellers

Aluminum alloys significantly influence impeller performance in terms of efficiency, durability, and application suitability. Below are the key impacts.

Hydraulic Efficiency

The low density and smooth surface finish of aluminum alloys reduce friction losses, improving hydraulic efficiency. For instance, 6061 and 2618 impellers with CNC-machined surfaces (Ra 0.4 µm) can increase pump efficiency by 3–5% compared to cast iron impellers. Computational Fluid Dynamics (CFD) studies show optimized blade designs enhance flow uniformity, reducing energy consumption.

Corrosion and Wear Resistance

While 6061 offers inherent corrosion resistance, 2000 series alloys (2024, 2601, 2618) and 7075 require surface treatments for aggressive environments. Anodized 2618 impellers demonstrate a corrosion rate of <0.1 mm/year in seawater, compared to 0.5 mm/year for untreated alloys. Wear resistance is critical in slurry pumps, where hard anodizing or ceramic coatings can extend service life by 20–30%.

Fatigue and Durability

The high strength-to-weight ratio of 2601 and 7075 alloys enhances fatigue resistance, crucial for impellers under cyclic loading. For example, 2601 impellers subjected to shot peening (shot size: 0.3 mm, velocity: 70 m/s) exhibit a 15% increase in fatigue life. Proper heat treatment further improves durability, ensuring reliable performance in high-speed applications like turbochargers.

Recent Advances in Aluminum Alloy Impellers

Recent research focuses on optimizing aluminum alloy impellers through advanced manufacturing and material science. Hybrid manufacturing, combining additive manufacturing with CNC machining, achieves complex geometries with surface roughness as low as Ra 0.2 µm. Nano-coatings, such as Al₂O₃ nanoparticles (10–20 nm), enhance wear resistance for 2618 impellers without compromising weight. CFD-coupled optimization of impeller blade profiles has led to efficiency gains of up to 6% in 6061-based designs.

Comparison of Aluminum Alloy Performance

The table below compares the performance of aluminum alloy series for impeller applications based on key metrics.

| 합금 | Efficiency Gain | 내식성 | 내마모성 | Fatigue Life |

|---|---|---|---|---|

| 2024 | 2–4% | 보통 | 보통 | 높음 |

| 2601 | 3–5% | 보통 | 보통 | 매우 높음 |

| 2618 | 3–5% | 보통 | High (with coating) | 높음 |

| 6061 | 3–5% | 높음 | 보통 | 보통 |

| 7075 | 4–6% | 보통 | High (with coating) | 매우 높음 |

결론

Aluminum alloys, including 2024, 2601, 2618, 6061, and 7075, are critical for impeller manufacturing due to their lightweight nature, strength, and versatility. Defined as aluminum combined with alloying elements like copper, magnesium, or zinc, these materials offer tailored properties for specific applications. Their widespread use is driven by cost-effectiveness, machinability, corrosion resistance, and thermal conductivity, outperforming alternatives like steel or titanium in many scenarios. By selecting appropriate alloys and manufacturing processes—such as CNC machining, casting, or additive manufacturing—and applying surface treatments like anodizing, industries can optimize impeller performance for efficiency, durability, and corrosion resistance. Ongoing advancements in material processing and design optimization continue to enhance the suitability of aluminum alloys for demanding impeller applications.