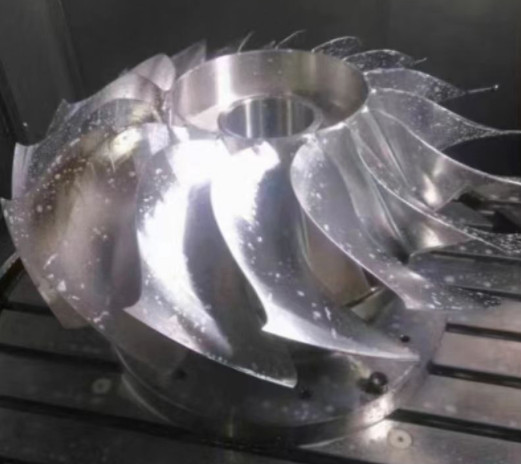

Aluminum alloy impellers are critical components in industries such as aerospace, automotive, and marine engineering due to their lightweight, high strength, and corrosion resistance. Machining these components requires precision to meet tight tolerances and complex geometries. The selection of coated cutting tools significantly influences machining efficiency, tool life, and surface quality. This article provides a comprehensive analysis of coated tool selection and performance for machining aluminum alloy impellers, focusing on tool materials, coatings, cutting parameters, and their impact on machining outcomes.

Properties of Aluminum Alloys for Impeller Machining

Aluminum alloys, such as 6061, 6082, 7075, and 2024, are commonly used for impellers due to their favorable mechanical properties. These alloys offer low density (approximately 2.7 g/cm³), high strength-to-weight ratio, and good corrosion resistance. However, their machinability presents challenges due to their ductility and low melting point (around 580–660°C), which can lead to material adhesion and built-up edge (BUE) formation on cutting tools. These properties necessitate careful tool selection to minimize wear and ensure high-quality surface finishes.

6061 aluminum alloy, for instance, contains magnesium and silicon, providing excellent formability and weldability. 7075, with zinc as the primary alloying element, offers superior strength comparable to some steels, making it ideal for high-stress impeller applications. 6082, a medium-strength alloy, is widely used due to its cost-effectiveness and good machinability. Understanding these material properties is essential for selecting appropriate tools and coatings to optimize machining performance.

Challenges in Machining Aluminum Alloy Impellers

Machining aluminum alloy impellers involves several difficulties that impact tool performance and workpiece quality. The primary issues include:

- Material Adhesion: Aluminum’s ductility leads to adhesion on the tool surface, forming BUE, which compromises surface finish and dimensional accuracy.

- Heat Generation: The low thermal conductivity of aluminum alloys (e.g., 167 W/m·K for 6061) causes heat accumulation at the tool-workpiece interface, accelerating tool wear.

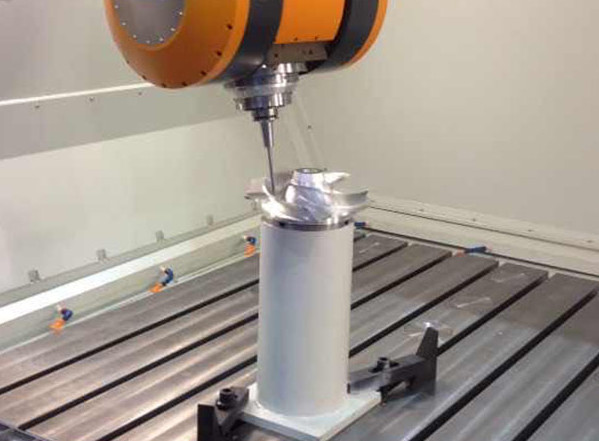

- Complex Geometries: Impellers feature thin-walled, intricate structures, requiring high-precision machining to avoid deformation and maintain dynamic balance.

- Surface Quality Requirements: Aerospace and automotive applications demand low surface roughness (Ra < 1 μm) and tight tolerances (±0.01 mm).

These challenges highlight the need for coated tools that reduce friction, enhance wear resistance, and maintain cutting efficiency under demanding conditions.

Coated Tool Materials for Aluminum Alloy Machining

The selection of tool materials and coatings is critical for addressing the challenges of machining aluminum alloys. Common tool materials include cemented carbide, polycrystalline diamond (PCD), and high-speed steel (HSS). Coatings such as titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC) are applied to enhance tool performance.

| Tool Material/Coating | 경도(HV) | Max Working Temp (°C) | 장점 | 제한 사항 |

|---|---|---|---|---|

| Cemented Carbide with TiN | 2500 | 600 | Good wear resistance, cost-effective | Moderate adhesion resistance |

| Cemented Carbide with TiAlN | 3000–3500 | 800–900 | High thermal stability, suitable for dry machining | Not optimal for low-silicon aluminum alloys |

| PCD | 8000–10000 | 700 | Excellent anti-sticking properties, long tool life | High cost, not suitable for ferrous materials |

| DLC-Coated Carbide | 5000–8000 | 250-300 | Low friction, excellent for aluminum alloys | Limited thermal stability |

PCD tools are highly effective for aluminum alloys due to their low affinity for aluminum, reducing BUE formation. DLC coatings offer low friction coefficients (0.1–0.2), improving chip evacuation and surface finish. TiN and TiAlN coatings provide good wear resistance but may be less effective in preventing adhesion compared to PCD or DLC.

Cutting Parameters for Optimal Performance

Cutting parameters significantly influence tool performance and machining outcomes. Key parameters include cutting speed (Vc), feed rate (fz), and depth of cut (ap). Typical ranges for machining aluminum alloy impellers are:

- 커팅 속도: 200–600 m/min

- 피드 속도: 0.05–0.2 mm/rev or mm/tooth

- 뎁스 오브 컷: 0.2–1.0 mm

Studies show that higher cutting speeds (e.g., 400–500 m/min) reduce BUE formation but increase tool wear due to elevated temperatures. Lower feed rates (e.g., 0.05–0.1 mm/rev) improve surface finish but may reduce material removal rate (MRR). A balance must be struck to optimize tool life and productivity. For instance, a cutting speed of 400 m/min, feed rate of 0.1 mm/rev, and depth of cut of 0.5 mm often yield good surface roughness (Ra ≈ 0.8 μm) and acceptable tool life (30–60 minutes).

Five-axis CNC machining is commonly used for impellers due to its ability to handle complex geometries. The use of variable helix end mills with chipbreaker geometry can further enhance chip evacuation and reduce cutting forces.

Tool Wear Mechanisms

Tool wear is a critical factor affecting machining performance. Common wear mechanisms in aluminum alloy impeller machining include:

- Adhesive Wear: Aluminum adheres to the tool surface, forming BUE, which leads to poor surface finish and increased cutting forces.

- Abrasive Wear: Silicon particles in certain aluminum alloys (e.g., Al-Si alloys) cause abrasive wear, particularly on uncoated or less hard coatings.

- Flank Wear: Observed as material loss on the tool’s flank face, typically measured as VB (flank wear width, e.g., 0.1–0.3 mm after 10–20 minutes of machining).

- Notch Wear: Localized wear at the depth-of-cut line, often exacerbated by high cutting speeds.

PCD and DLC-coated tools exhibit superior resistance to adhesive wear due to their low friction and anti-sticking properties. TiAlN coatings are effective against abrasive wear but may experience flaking under high-speed conditions. Tool life varies significantly, with PCD tools lasting 50–100 minutes compared to 10–30 minutes for TiN-coated carbide tools under similar conditions (Vc = 400 m/min, fz = 0.1 mm/rev, ap = 0.5 mm).

Surface Quality and Dimensional Accuracy

Surface quality is paramount for aluminum alloy impellers, as it affects aerodynamic performance and fatigue life. Surface roughness metrics such as Ra (average roughness) and Rz (maximum height of the profile) are commonly evaluated. Typical requirements for impellers include Ra < 1 μm and dimensional tolerances of ±0.01 mm.

Coated tools, particularly PCD and DLC, achieve lower Ra values (0.5–0.8 μm) compared to uncoated carbide (1.2–2.0 μm) due to reduced adhesion. TiN-coated tools also provide good surface finishes but are less effective than PCD in high-speed machining. Dimensional accuracy is improved with five-axis CNC machining, which allows precise control over tool paths and minimizes deformation in thin-walled impeller blades.

Cooling strategies, such as minimum quantity lubrication (MQL) or dry machining, also influence surface quality. MQL with vegetable oil (50 mL/h, 6 bar pressure) reduces surface roughness by up to 23.7% compared to dry machining, although dry conditions are often preferred for environmental reasons.

Performance Analysis of Coated Tools

The performance of coated tools can be evaluated based on tool life, cutting forces, and surface quality. The following table summarizes the performance of different coated tools under typical machining conditions (Vc = 400 m/min, fz = 0.1 mm/rev, ap = 0.5 mm):

| Coating | Tool Life (min) | Cutting Force (N) | Surface Roughness (Ra, μm) |

|---|---|---|---|

| TiN | 10–30 | 200–300 | 0.8–1.2 |

| TiAlN | 15–40 | 180–250 | 0.7–1.0 |

| DLC | 20-50 | 150–200 | 0.6–0.9 |

| PCD | 50-100 | 100–150 | 0.5–0.8 |

PCD tools consistently outperform others in terms of tool life and surface quality, though their high cost may limit their use in cost-sensitive applications. DLC-coated tools offer a cost-effective alternative with comparable performance in low-temperature conditions. TiAlN is suitable for high-speed machining but requires careful parameter optimization to minimize wear.

Practical Recommendations for Tool Selection

Based on the analysis, the following recommendations are provided for selecting coated tools for aluminum alloy impeller machining:

- High-Precision Applications: Use PCD tools for aerospace impellers requiring Ra < 0.8 μm and tolerances of ±0.01 mm. Their superior anti-sticking properties and long tool life justify the higher cost.

- Cost-Sensitive Applications: DLC-coated carbide tools are recommended for general-purpose machining, offering good performance at a lower cost.

- High-Speed Machining: TiAlN-coated tools are suitable for cutting speeds above 400 m/min, provided MQL is used to manage heat.

- 툴 지오메트리: Select tools with high rake angles (10–20°) and chipbreaker designs to improve chip evacuation and reduce cutting forces.

- Machining Environment: Prefer dry machining or MQL to minimize environmental impact while maintaining surface quality.

Regular monitoring of tool wear using scanning electron microscopy (SEM) or acoustic emission techniques can help optimize tool change intervals and prevent quality issues.

결론

The machining of aluminum alloy impellers requires careful selection of coated tools to address challenges such as material adhesion, heat generation, and complex geometries. PCD and DLC-coated tools offer superior performance in terms of tool life and surface quality, while TiAlN and TiN coatings provide cost-effective alternatives for specific conditions. By optimizing cutting parameters and tool geometry, manufacturers can achieve high precision, efficiency, and surface quality. This analysis provides a systematic guide for selecting and evaluating coated tools, ensuring reliable and high-quality machining of aluminum alloy impellers.