Aluminum alloy impellers are critical components in industries such as aerospace, automotive, and marine, requiring high precision and efficiency during machining. High-speed cutting (HSC) is widely adopted for its ability to achieve superior surface quality and productivity. The selection of appropriate cutting tools is paramount to ensure optimal performance, tool life, and workpiece integrity. This article provides a systematic analysis of tool selection for high-speed machining of aluminum alloy impellers, focusing on tool materials, geometries, coatings, and cutting parameters. The content is structured to offer practical, experience-based insights for professionals seeking reliable and technical guidance.

Tool Material Selection

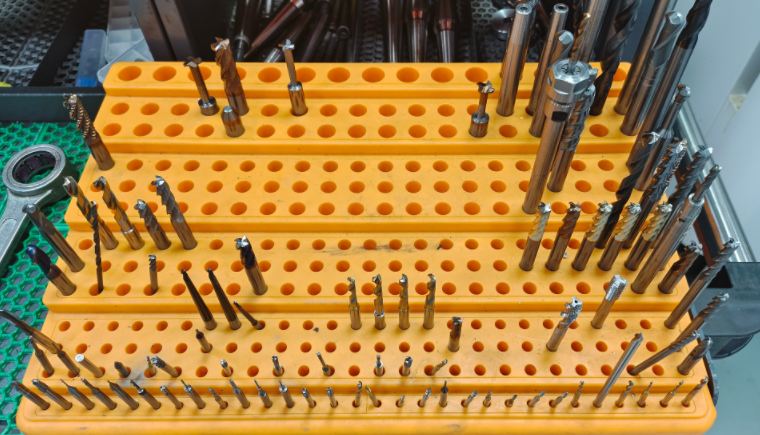

The choice of tool material is fundamental in high-speed machining of 알루미늄 합금 due to the material’s softness, high thermal conductivity, and tendency to adhere to cutting edges. The primary tool materials for this application are cemented carbide, polycrystalline diamond (PCD), and high-speed steel (HSS), with carbide and PCD being the most suitable for HSC.

Cemented Carbide: Carbide tools, particularly those with fine-grain substrates, are preferred for their hardness and wear resistance. They can withstand cutting speeds ranging from 800 to 2500 m/min, depending on the alloy and operation. Carbide tools are cost-effective for most impeller machining tasks, offering a balance between performance and affordability.

Polycrystalline Diamond (PCD): PCD tools are ideal for high-precision finishing operations due to their low coefficient of friction, high thermal conductivity, and chemical inertness. They excel in machining high-silicon aluminum alloys, reducing built-up edge (BUE) formation. PCD tools can operate at speeds up to 5000 m/min but are more expensive, limiting their use to applications requiring exceptional surface finish.

High-Speed Steel (HSS): HSS is less suitable for HSC due to its lower hardness under high cutting conditions. It is typically used for low-speed operations or when cost constraints are significant, but it cannot match the performance of carbide or PCD in high-speed impeller machining.

Practical Recommendation: For general-purpose machining of aluminum alloy impellers, fine-grain carbide tools are recommended. PCD tools should be reserved for finishing operations on high-silicon alloys or when surface roughness requirements are stringent (e.g., Ra < 0.8 µm).

Tool Geometry Considerations

Tool geometry significantly influences chip formation, cutting forces, and surface quality in high-speed machining. Key geometric parameters include rake angle, helix angle, number of flutes, and edge preparation.

Rake Angle: A high positive rake angle (15° to 25°) is recommended for aluminum alloys to reduce cutting forces and improve chip evacuation. In roughing operations, a slightly lower rake angle (10° to 15°) enhances tool strength, while finishing operations benefit from higher angles to minimize surface roughness.

Helix Angle: A helix angle of 35° to 45° is optimal for high-speed milling of aluminum impellers. A 45° helix angle is preferred for finishing due to its aggressive cutting action and improved chip evacuation, while a 35° angle suits roughing by providing better tool stability.

Number of Flutes: Two or three-flute end mills are most effective for aluminum machining. Two-flute tools maximize chip evacuation space, reducing the risk of chip clogging in deep pockets or complex impeller geometries. Three-flute tools offer higher rigidity and are suitable for finishing operations where surface quality is critical. Four or more flutes are generally avoided as they reduce chip evacuation efficiency.

Edge Preparation: Chamfered or honed edges enhance tool strength and reduce chipping. A chamfer width of 0.02 to 0.05 mm is typical for carbide tools, while PCD tools may use a sharp edge for finishing to achieve superior surface quality.

Practical Recommendation: Use two-flute carbide end mills with a 35° helix angle and 15° rake angle for roughing, and three-flute PCD tools with a 45° helix angle for finishing. Ensure proper edge preparation to balance tool life and surface quality.

Tool Coatings

Coatings play a critical role in reducing friction, preventing BUE, and extending tool life. However, not all coatings are suitable for aluminum alloy machining due to the material’s adhesive nature.

Uncoated Tools: Polished, uncoated carbide tools are often preferred for aluminum machining. The polished surface reduces friction and minimizes material adhesion, improving chip evacuation and surface finish. Uncoated tools are cost-effective and perform well at cutting speeds of 800 to 1500 m/min.

Diamond-Like Carbon (DLC) Coating: DLC coatings are suitable for machining high-silicon aluminum alloys, offering low friction and high wear resistance. They are particularly effective for aerospace-grade alloys (e.g., 7075 or 2024) at speeds up to 2000 m/min.

Zirconium Nitride (ZrN) Coating: ZrN coatings provide moderate friction reduction and are occasionally used for general-purpose aluminum machining. However, they are less effective than DLC or uncoated tools for high-speed applications.

Avoided Coatings: Coatings like TiN, TiAlN, and AlTiN are unsuitable for aluminum due to their chemical reactivity and rougher surface, which promote BUE formation and increase friction.

Practical Recommendation: Use polished, uncoated carbide tools for most impeller machining tasks. For high-silicon alloys or high-speed finishing, consider DLC-coated tools to enhance performance.

Cutting Parameters Optimization

Optimizing cutting parameters—cutting speed, feed rate, and depth of cut—is essential for achieving efficient material removal, minimizing tool wear, and ensuring surface quality. The following parameters are tailored for aluminum alloy impeller machining.

커팅 속도: Cutting speeds typically range from 800 to 2500 m/min for carbide tools and up to 5000 m/min for PCD tools, depending on the alloy. For common alloys like 6061, a speed of 1000 to 1500 m/min is effective, while 7075 may require 1200 to 2000 m/min due to its higher hardness.

피드 속도: Feed per tooth (fz) should be set between 0.05 and 0.15 mm/tooth for carbide tools and 0.02 to 0.10 mm/tooth for PCD tools. For a two-flute tool at 12000 RPM, this translates to a feed rate of 1200 to 3600 mm/min. Higher feed rates improve productivity but must be balanced to avoid excessive tool wear.

뎁스 오브 컷: Axial depth of cut (ap) should be 0.05 to 0.25 mm for finishing and 0.5 to 2 mm for roughing. Radial depth of cut (ae) is typically 50% to 80% of the tool diameter for roughing and 10% to 20% for finishing to minimize cutting forces.

| Operation | 도구 재질 | 절단 속도(m/min) | Feed per Tooth (mm/tooth) | Axial Depth of Cut (mm) |

|---|---|---|---|---|

| 러프닝 | 카바이드 | 800–1500 | 0.08–0.15 | 0.5–2 |

| 마무리 | PCD | 1500–5000 | 0.02–0.10 | 0.05–0.25 |

Practical Recommendation: Start with conservative parameters (e.g., 1000 m/min, 0.08 mm/tooth, 1 mm depth) and adjust based on tool wear, surface finish, and machine performance. Use high-speed machining strategies like trochoidal milling for complex impeller geometries to maintain constant tool engagement.

Coolant and Lubrication Strategies

Coolant and lubrication are critical in high-speed machining to manage heat, reduce BUE, and improve chip evacuation. Aluminum’s high thermal conductivity allows for effective heat dissipation, but improper coolant use can exacerbate adhesion issues.

Minimum Quantity Lubrication (MQL): MQL with vegetable-based oils (e.g., olive oil at 150 mL/hr) is highly effective for aluminum machining. It reduces friction, minimizes BUE, and is environmentally friendly. MQL is preferred for high-speed operations to avoid excessive coolant residue.

Dry Machining: Dry machining is viable for high-speed milling with PCD tools due to lower cutting temperatures at elevated speeds. However, it requires robust chip evacuation systems to prevent chip recutting.

Flood Coolant: Water-soluble cutting fluids are suitable for general-purpose machining but should be used sparingly to avoid chip adhesion. A concentration of 5% to 10% is typical for aluminum alloys.

Practical Recommendation: Use MQL for most high-speed impeller machining tasks to balance performance and sustainability. Reserve dry machining for finishing with PCD tools and flood coolant for roughing with carbide tools.

Machine and Workpiece Considerations

The machining system, including the CNC machine and workpiece setup, influences tool performance and process stability. Aluminum alloy impellers often feature thin-walled or complex geometries, requiring careful consideration.

Machine Rigidity: High-speed machining requires rigid CNC machines with spindle speeds of 12000 to 40000 RPM. Machines like the Haas VF3ss or DMG MORI HSC series are suitable for impeller machining, providing the necessary precision and stability.

Workpiece Fixturing: Secure fixturing is essential to minimize vibration, especially for thin-walled impellers. Vacuum chucks or custom clamps designed for the impeller’s geometry ensure stability and reduce deformation.

Tool Path Strategies: Use high-efficiency milling (HEM) or trochoidal tool paths to maintain constant tool engagement and reduce cutting forces. These strategies are particularly effective for complex impeller blades, improving tool life and surface quality.

Practical Recommendation: Select a high-rigidity CNC machine with a spindle speed of at least 12000 RPM. Use custom fixturing and HEM tool paths to optimize machining of complex impeller geometries.

결론

High-speed cutting tool selection for aluminum alloy impeller machining requires a systematic approach, considering tool materials, geometries, coatings, cutting parameters, coolant strategies, and machine setup. Fine-grain carbide tools are versatile for roughing and general-purpose machining, while PCD tools excel in finishing high-silicon alloys. Optimized geometries (e.g., high rake and helix angles) and appropriate coatings (e.g., DLC or uncoated) enhance performance. Cutting parameters should balance material removal rates with tool life, and MQL is recommended for most applications. By integrating these factors, manufacturers can achieve high precision, efficiency, and reliability in impeller machining.