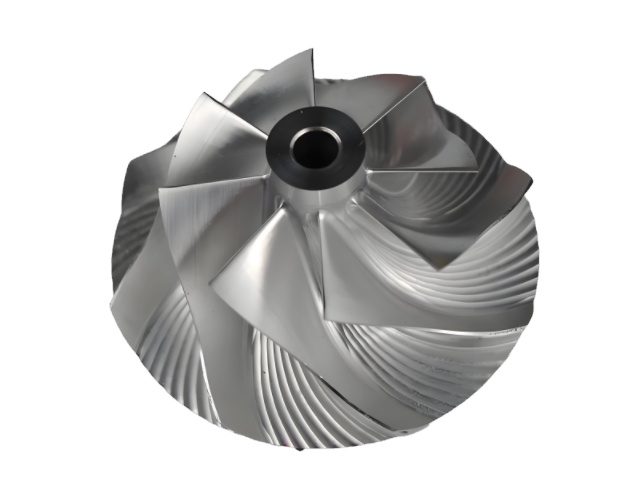

Impellers in high-temperature environments, such as those in aerospace jet engines, industrial turbines, and chemical processing systems, must withstand extreme thermal, mechanical, and corrosive stresses. Selecting materials that maintain structural integrity and performance under such conditions is critical for operational efficiency and safety. This article examines key high-temperature impeller materials, their properties, applications, and performance metrics, providing a comprehensive guide for engineers and researchers.

Key Material Requirements for High-Temperature Impellers

High-temperature impellers operate in environments exceeding 1000°C, often under high mechanical stress, corrosive gases, or rapid thermal cycling. The materials must exhibit specific properties to ensure durability and performance:

- High Melting Point: Materials must resist melting or deformation at temperatures above 1000°C, with some applications requiring stability up to 2000°C.

- Thermal Shock Resistance: The ability to withstand rapid temperature changes without cracking or losing strength.

- 기계적 강도: High tensile strength and fatigue resistance to endure rotational stresses and vibrations.

- 내식성: Resistance to oxidation and chemical degradation in harsh environments, such as those involving hot gases or corrosive fluids.

- 낮은 열 전도성: For applications requiring thermal insulation to protect internal components.

- Lightweight: Particularly in aerospace, reducing weight improves fuel efficiency and performance.

These requirements guide the selection of materials such as superalloys, refractory metals, ceramics, and advanced composites, each tailored to specific operational demands.

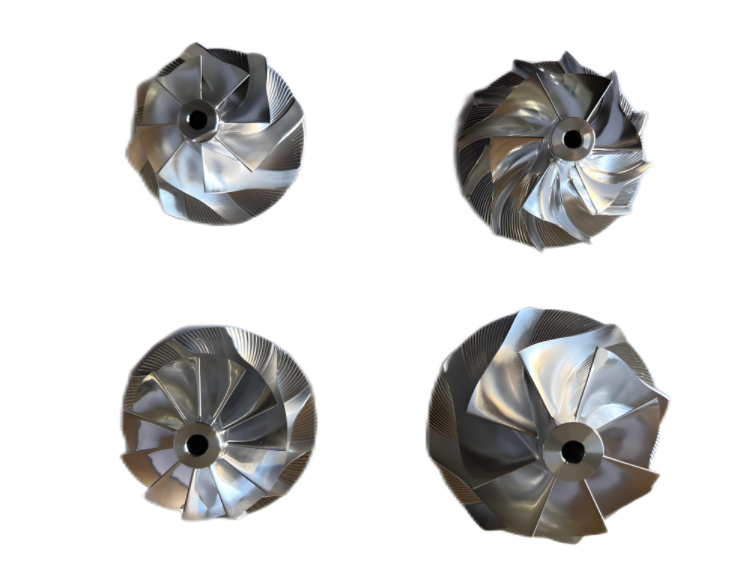

Primary Material Classes for High-Temperature Impellers

Several material classes are suitable for high-temperature impellers, each with distinct properties and applications. Below is an in-depth analysis of the most commonly used materials.

Superalloys

Superalloys, primarily nickel-based, are widely used in high-temperature impellers due to their excellent mechanical strength and resistance to creep and oxidation at elevated temperatures. Inconel, a popular nickel-chromium superalloy, is particularly valued in aerospace and industrial turbines.

| 재료 | Melting Point (°C) | Max Operating Temp (°C) | 주요 속성 | 애플리케이션 |

|---|---|---|---|---|

| 인코넬 718 | 1336 | 980 | High strength, corrosion resistance, good weldability | Jet engines, gas turbines |

| Inconel 625 | 1350 | 1000 | Oxidation resistance, fatigue strength | Chemical processing, aerospace |

Inconel alloys maintain structural integrity up to 1000°C, with creep resistance enhanced by alloying elements like molybdenum and niobium. Their ability to withstand saltwater and acidic environments makes them suitable for impellers in marine and chemical applications.

Refractory Metals

Refractory metals, such as tungsten, molybdenum, and tantalum, are characterized by melting points above 2000°C, making them ideal for extreme heat applications. These metals are harder at room temperature and resist deformation under thermal stress.

| 재료 | Melting Point (°C) | Max Operating Temp (°C) | 주요 속성 | 애플리케이션 |

|---|---|---|---|---|

| Tungsten | 3422 | 2000 | High density, extreme heat resistance | High-temperature furnaces, aerospace |

| Molybdenum | 2623 | 1900 | High strength, corrosion resistance | Industrial turbines, chemical processing |

| Tantalum | 3017 | 1800 | Corrosion resistance, biocompatibility | Chemical reactors, medical implants |

Tungsten and molybdenum are used in impellers for high-temperature industrial furnaces and gas turbines, while tantalum’s corrosion resistance suits chemical processing environments. However, their high density can be a drawback in weight-sensitive applications like aerospace.

Ceramics and Ultra-High Temperature Ceramics (UHTCs)

Ceramics, including silicon carbide (SiC) and ultra-high temperature ceramics (UHTCs) like zirconium diboride (ZrB2), offer exceptional thermal stability and low thermal conductivity. UHTCs are particularly suited for hypersonic applications where temperatures exceed 2000°C.

SiC impellers are used in high-temperature gas turbines due to their hardness and thermal shock resistance. UHTCs, with melting points above 3000°C, are being developed for hypersonic vehicle components, where impellers must endure extreme thermal and mechanical loads. Their low density and high porosity make them effective insulators, protecting internal systems.

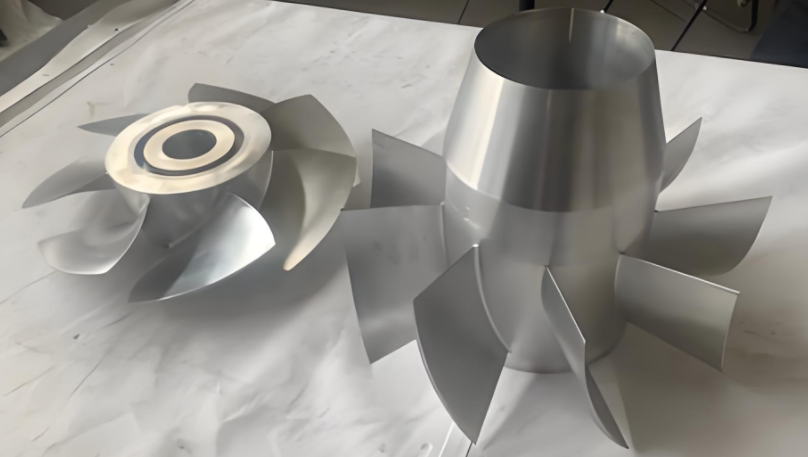

High-Temperature Composites

Composites, such as carbon-fiber-reinforced silicon carbide (C/SiC) and ultra-high temperature ceramic matrix composites (UHTCMCs), combine the thermal resistance of ceramics with the toughness of fibers. These materials are lightweight and resistant to thermal shock, making them ideal for aerospace impellers.

C/SiC composites are used in jet engine impellers, offering a balance of strength and weight reduction. UHTCMCs, incorporating high-entropy carbides and borides, are emerging for next-generation hypersonic applications, with ongoing research focusing on scalability and cost-effectiveness.

Applications of High-Temperature Impellers

High-temperature impellers are critical in various industries, each with unique environmental challenges:

- 항공우주: Impellers in jet engines and hypersonic vehicles operate at temperatures up to 2000°C, requiring materials like superalloys and UHTCs for durability and fuel efficiency.

- Industrial Turbines: Gas turbines in power generation use superalloys and ceramics to withstand high temperatures and mechanical stress.

- Chemical Processing: Impellers in reactors handling corrosive fluids rely on refractory metals like tantalum for corrosion resistance.

- High-Temperature Furnaces: Tungsten and molybdenum impellers are used in furnaces operating above 1500°C, ensuring long service life.

Each application demands specific material properties, with trade-offs between cost, weight, and performance influencing material selection.

Challenges and Future Directions

Developing high-temperature impeller materials faces several challenges:

- 비용: Refractory metals and UHTCs are expensive to produce and process, limiting their widespread adoption.

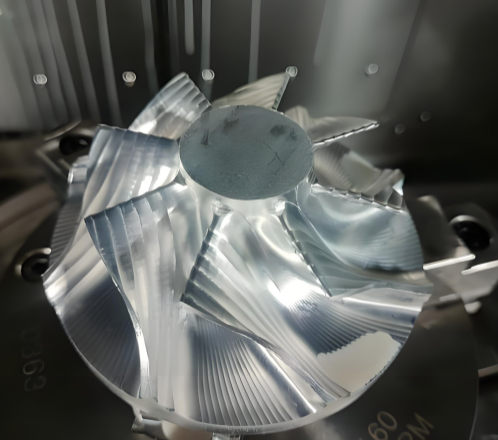

- Manufacturing: Additive manufacturing and high-throughput computational techniques are being explored to reduce costs and improve material properties.

- Testing: Simulating extreme conditions, such as high-pressure and high-temperature environments, requires advanced testing facilities to ensure material reliability.

Future research focuses on optimizing material compositions using computational modeling, developing scalable manufacturing processes, and integrating nanostructures to enhance thermal and mechanical properties. For example, NASA’s GRX-810 alloy, developed using 3D printing, demonstrates improved strength and durability at 2000°F, highlighting the potential of advanced manufacturing techniques.

결론

High-temperature impellers require materials that balance thermal stability, mechanical strength, and corrosion resistance. Superalloys like Inconel, refractory metals like tungsten, ceramics like SiC, and advanced composites like UHTCMCs each offer unique advantages for specific applications. By understanding their properties and leveraging emerging technologies like additive manufacturing, engineers can design impellers that meet the demands of extreme environments, driving advancements in aerospace, energy, and industrial sectors.