Surface brushing treatment is a common finishing process applied to impellers in centrifugal pumps to improve surface quality, enhance corrosion resistance, and meet aesthetic requirements. However, its impact on impeller dynamic balancing, a critical factor in ensuring smooth operation and longevity of rotating machinery, requires careful examination. This article provides a technical and systematic analysis of how surface brushing affects impeller dynamic balancing, focusing on mechanisms, quantifiable effects, and practical considerations. The discussion is grounded in engineering principles, supported by relevant parameters, and structured to address key aspects of the process.

What is Impeller Dynamic Balancing

Dynamic balancing is the process of ensuring that an impeller's mass distribution is uniform around its rotational axis to minimize vibrations during operation. Imbalance in an impeller can lead to excessive vibratory forces, which accelerate bearing wear, reduce pump efficiency, and potentially cause mechanical failure. The International Organization for Standardization (ISO) 21940-11 standard specifies balance quality grades, such as G2.5 for pump impellers, which define permissible residual unbalance based on impeller weight and rotational speed.

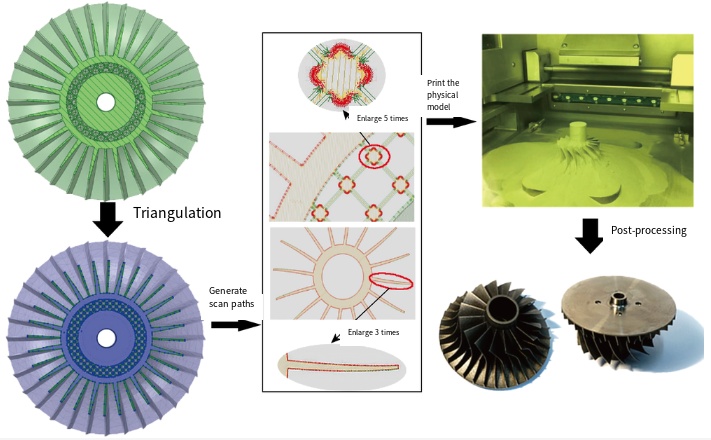

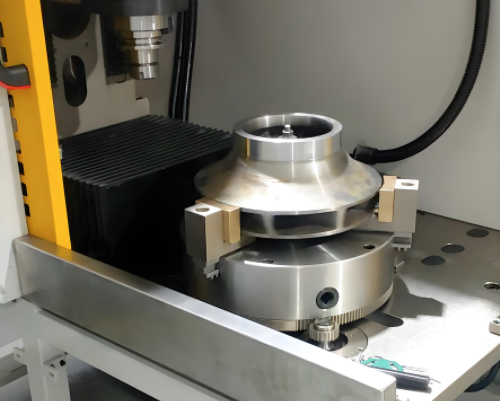

The dynamic balancing process typically involves mounting the impeller on a balancing machine, spinning it at a specified speed (e.g., 1800 RPM), and measuring unbalance using sensors. Corrections are made by adding or removing material, often through grinding or welding, to achieve a residual unbalance within acceptable limits, such as 0.001 oz-in for precision applications. For multi-stage pumps, balancing may involve both single-plane and two-plane methods, depending on the impeller's geometry and operational speed.

Key parameters in dynamic balancing include:

- Balance Grade (G): G2.5 is commonly required for pump impellers, corresponding to a maximum permissible unbalance velocity of 2.5 mm/s.

- Residual Unbalance (Uper): Calculated as Uper = (1000 × G × impeller weight in kg) / angular velocity in rad/s. For example, a 2 kg impeller at 3000 RPM (314.2 rad/s) has a permissible unbalance of 15.91 g-mm (0.022 oz-in).

- Correction Planes: Single-plane balancing is sufficient for impellers with a length-to-diameter ratio less than 0.5 and speeds below 1000 RPM, while two-plane balancing is required for higher speeds or complex geometries.

These parameters ensure that the impeller operates within acceptable vibration limits, typically reducing bearing loads and extending service life.

Surface Brushing Treatment: Process and Purpose

Surface brushing treatment involves mechanically abrading the impeller surface using wire brushes or abrasive tools to create a uniform, linear texture. This process is distinct from polishing, as it does not aim to achieve a mirror-like finish but rather a consistent surface pattern. The primary purposes of surface brushing 포함:

- Surface Uniformity: Removing minor surface irregularities, such as casting defects or machining marks, to improve fluid flow characteristics.

- 내식성: Enhancing resistance to environmental factors, particularly in impellers exposed to corrosive fluids like seawater or chemicals.

- Aesthetic Improvement: Providing a visually appealing finish for applications where appearance is a consideration.

The brushing process typically removes a thin layer of material, with removal depths ranging from 0.01 to 0.1 mm, depending on the abrasive tool and applied pressure. Materials commonly used for impellers, such as stainless steel, titanium, or composites, respond differently to brushing due to variations in hardness and ductility.

While surface brushing improves surface quality, it introduces potential changes to the impeller's mass distribution. These changes can affect dynamic balancing, particularly if the material removal is uneven or if the brushing process alters the impeller's geometry in critical areas, such as the blades or shrouds.

Mechanisms of Surface Brushing Impact on Dynamic Balancing

Surface brushing can influence impeller dynamic balancing through several mechanisms, each related to changes in mass distribution or structural integrity. The following sections detail these mechanisms and their implications.

Material Removal and Mass Distribution

Surface brushing removes material from the impeller surface, potentially altering its center of gravity. Even small amounts of material removal can introduce unbalance, especially in high-speed applications where precision is critical. For example, removing 0.01 mm of material from a 2 kg stainless steel impeller with a 200 mm diameter can result in a mass loss of approximately 0.1 g, depending on the brushed area. If this removal is uneven—due to inconsistent brushing pressure or tool wear—the resulting eccentricity between the center of gravity and the rotational axis can exceed the permissible unbalance (e.g., 15.91 g-mm for a G2.5 grade at 3000 RPM).

In single-plane balancing, this unbalance is corrected by adjusting material in one plane, typically the impeller's outer diameter. For two-plane balancing, uneven material removal on the front and back shrouds can introduce couple unbalance, requiring corrections at axially separated locations. The table below summarizes the impact of material removal on unbalance for a sample impeller:

| 매개변수 | Value | Impact on Unbalance |

|---|---|---|

| Impeller Weight | 2 kg | Base mass for Uper calculation |

| 회전 속도 | 3000 RPM (314.2 rad/s) | Determines permissible unbalance (15.91 g-mm) |

| Material Removed | 0.1 g (uneven) | Introduces eccentricity of ~0.05 mm, exceeding G2.5 limit |

Surface Roughness and Hydraulic Effects

Surface brushing alters the impeller's surface roughness, which affects hydraulic performance and, indirectly, dynamic balancing. Increased surface roughness can lead to higher disk friction losses, reducing pump efficiency by up to 3-5% in multistage centrifugal pumps. These losses create uneven hydraulic loading on the impeller blades, which may manifest as vibrations that mimic imbalance. For instance, a surface roughness increase from Ra 0.8 µm to Ra 3.2 µm can increase hydraulic losses by 2%, potentially requiring recalibration of the impeller's balance to account for these dynamic forces.

Computational Fluid Dynamics (CFD) studies indicate that surface roughness primarily affects hydraulic efficiency rather than direct mass imbalance. However, in high-speed pumps (>1800 RPM), these hydraulic effects can amplify vibrations, necessitating dynamic balancing to stricter tolerances (e.g., G1.0 instead of G2.5).

Structural Integrity and Blade Geometry

Surface brushing can inadvertently alter the impeller's blade geometry, particularly in open or semi-open impellers where blades are directly exposed to the brushing tool. Uneven brushing may thin certain blades, shifting the impeller's mass distribution and introducing dynamic unbalance. For example, a 0.05 mm reduction in blade thickness on one side of a 200 mm diameter impeller can shift the center of gravity by 0.02 mm, resulting in an unbalance of approximately 0.04 oz-in, which exceeds typical G2.5 tolerances.

Additionally, brushing can introduce micro-cracks or stress concentrations in brittle materials like cast iron, potentially affecting the impeller's structural integrity. These defects may not directly cause imbalance but can lead to uneven wear during operation, further complicating dynamic balancing efforts.

Practical Considerations for Surface Brushing and Balancing

To mitigate the impact of surface brushing on dynamic balancing, engineers must adopt a systematic approach during impeller manufacturing and maintenance. The following considerations are critical:

Pre-Brushing Balancing

Balancing the impeller before surface brushing ensures that the initial mass distribution is optimized. This approach allows brushing to be applied uniformly, minimizing the risk of introducing new imbalances. For example, single-plane balancing to G6.3 or G2.5 can be performed using a static balancing machine, followed by brushing with controlled parameters (e.g., consistent brush pressure and speed).

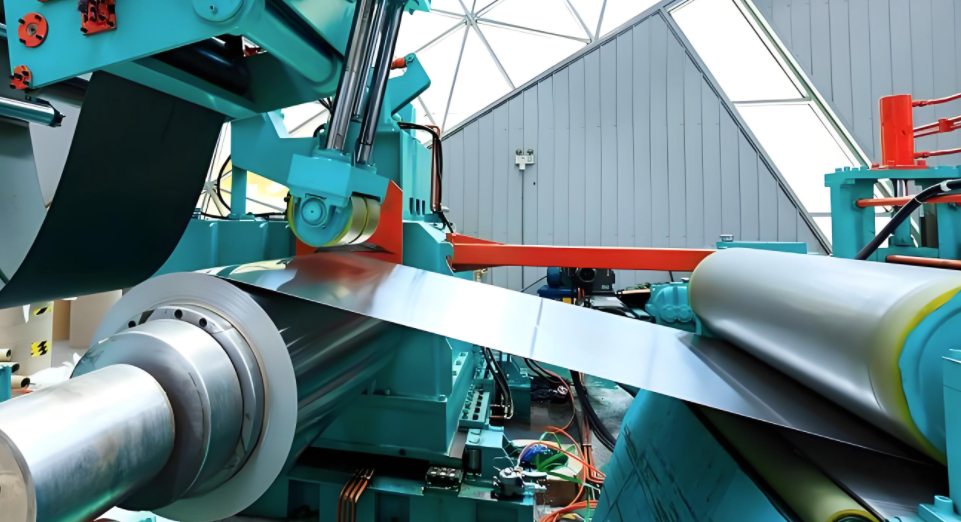

Controlled Brushing Parameters

Standardizing brushing parameters, such as brush type, pressure, and duration, reduces variability in material removal. For instance, using a stainless steel wire brush with a pressure of 2-3 bar and a brushing speed of 500 RPM ensures uniform material removal of approximately 0.02 mm across the impeller surface. Automated brushing systems can further enhance consistency, reducing the risk of uneven mass distribution.

Post-Brushing Balancing Verification

After brushing, the impeller should be rechecked on a dynamic balancing machine to verify compliance with ISO 21940-11 standards. If the residual unbalance exceeds the permissible limit (e.g., 0.022 oz-in for a 2 kg impeller at 3000 RPM), corrective measures, such as localized grinding or adding balance weights, should be applied. The table below outlines typical post-brushing balancing tolerances:

| Balance Grade | Permissible Unbalance (g-mm) | Application |

|---|---|---|

| G6.3 | 39.77 (0.055 oz-in) | General-purpose pumps |

| G2.5 | 15.91 (0.022 oz-in) | High-speed or precision pumps |

| G1.0 | 6.36 (0.009 oz-in) | Aerospace or critical applications |

소재 및 디자인 고려 사항

The choice of impeller material and design influences the impact of brushing on balancing. Materials with high ductility, such as stainless steel, are less prone to micro-cracks during brushing, while brittle materials like cast iron require careful handling. Additionally, impellers with symmetrical blade designs are less sensitive to uneven brushing compared to single-blade or asymmetrical designs.

Case Study: Balancing a Brushed Impeller

Consider a 2 kg stainless steel impeller for a centrifugal pump operating at 3000 RPM. The impeller undergoes surface brushing to achieve a surface roughness of Ra 1.6 µm, removing approximately 0.05 g of material. Pre-brushing balancing achieves a residual unbalance of 10 g-mm (G2.5 grade). Post-brushing, the unbalance increases to 20 g-mm due to uneven material removal on the front shroud. Dynamic balancing on a machine at 1800 RPM reveals a couple unbalance, requiring corrections of 0.02 g at 0° on the front shroud and 0.03 g at 180° on the back shroud. After correction, the residual unbalance is reduced to 12 g-mm, within the G2.5 tolerance.

This case highlights the importance of post-brushing balancing to address unbalance introduced by surface treatment, ensuring the impeller meets operational requirements.

결론

Surface brushing treatment can impact impeller dynamic balancing by altering mass distribution, surface roughness, and blade geometry. While the material removal is typically small, uneven brushing can introduce unbalance that exceeds ISO 21940-11 tolerances, particularly in high-speed or precision applications. Engineers can mitigate these effects by balancing the impeller before and after brushing, standardizing brushing parameters, and verifying balance post-treatment. By understanding the mechanisms and applying rigorous balancing procedures, manufacturers can ensure that brushed impellers maintain optimal performance and reliability in centrifugal pumps.