Impeller surface treatments are critical in optimizing the performance, efficiency, and longevity of impellers used in pumps, turbines, and mixers across industries such as wastewater treatment, chemical processing, and energy production. This article explores the types of surface treatments, their processes, and their effects on impeller performance, supported by detailed parameters and structured data.

Overview of Impeller Surface Treatments

Surface treatments modify the surface properties of impellers to enhance their resistance to corrosion, wear, and cavitation, while improving hydraulic efficiency and reducing energy consumption. These treatments are applied to impellers made from materials like stainless steel, aluminum, or Inconel, depending on the application. The choice of treatment depends on factors such as operating conditions, fluid type, and desired performance outcomes.

Types of Impeller Surface Treatments

Several surface treatment methods are employed to improve impeller performance. Below is a detailed examination of the most common types, their applications, and their specific benefits.

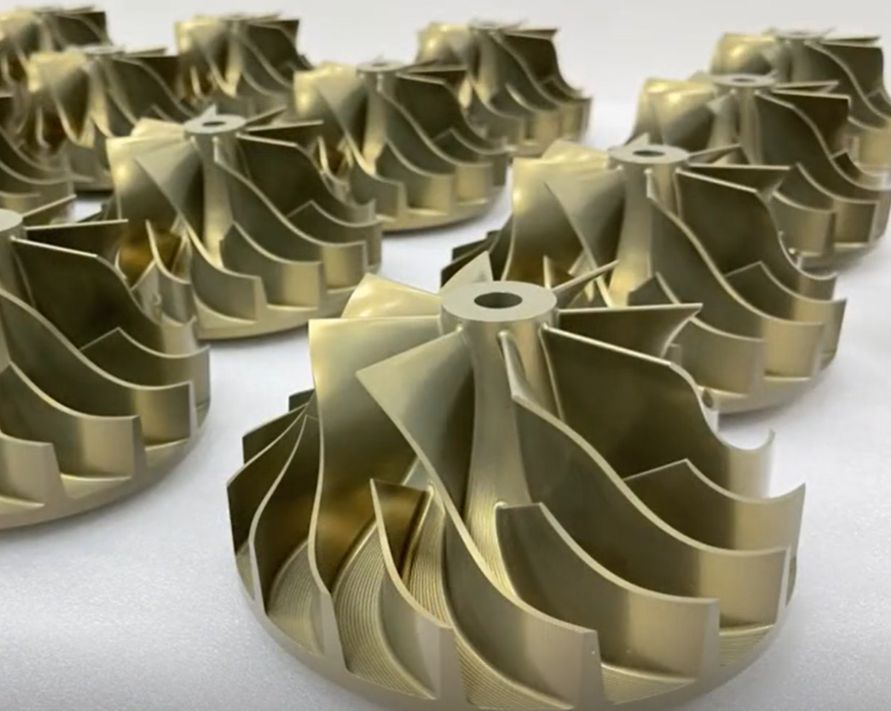

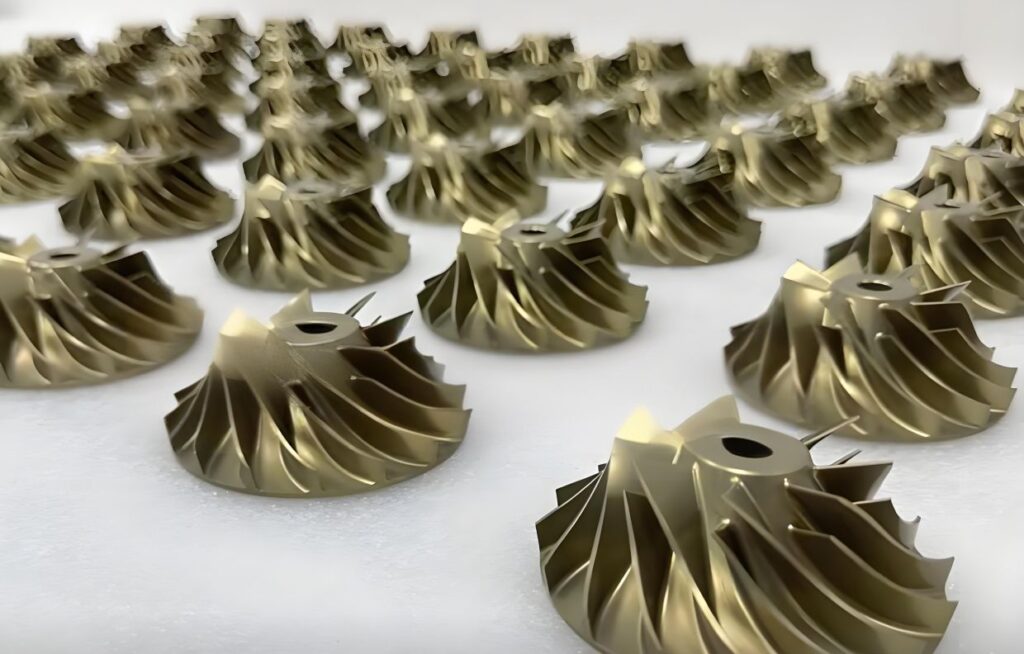

Abrasive Flow Machining (AFM)

Abrasive Flow Machining (AFM) involves passing a viscous, abrasive-laden media through the impeller's internal passages to polish and deburr surfaces. This process is particularly effective for closed impellers with complex geometries, as it ensures uniform material removal and improves surface roughness. AFM can reduce surface roughness from Ra 0.8 µm to Ra 0.2 µm, depending on the initial surface condition. It is widely used in applications requiring high efficiency, such as in mechanically pumped fluid loop systems for space applications.

Shot Peening and Blasting

Shot peening and blasting involve bombarding the impeller surface with small spherical media to induce compressive residual stresses and remove surface impurities. Shot peening focuses on enhancing fatigue strength by creating a uniform layer of compressive stress, while shot blasting prioritizes surface cleaning and scale removal. Parameters such as shot ball size (0.2–1.0 mm), velocity (50–100 m/s), and impact angle (45°–90°) significantly affect coverage and uniformity. These processes are critical in industries like zinc hydrometallurgy, where impellers face erosive and corrosive slurries.

Coating and Plating

Coating and plating involve applying a thin layer of material, such as zinc, nickel, or ceramic, to the impeller surface to enhance corrosion resistance and reduce wear. For example, zinc phosphate coatings are applied to steel impellers via immersion in phosphoric acid, while galvanic coatings can be applied through hot-dip or electroplating methods. These treatments improve durability in aggressive environments, such as those involving high-temperature or chemically reactive fluids.

아노다이징

Anodizing is primarily used for aluminum impellers, creating a protective aluminum oxide layer through immersion in an electrolytic solution with sulfuric acid. This process enhances wear resistance and environmental durability. Hard anodizing can increase surface hardness to 400–600 HV, significantly extending impeller lifespan in applications like wastewater treatment.

Surface Treatment Processes and Parameters

The effectiveness of surface treatments depends on precise control of process parameters. The table below summarizes key processes and their critical parameters.

| Treatment Type | Process Description | Key Parameters | 애플리케이션 |

|---|---|---|---|

| Abrasive Flow Machining (AFM) | Viscous media with abrasive grits flows through impeller passages | Media viscosity: 100–500 Pa·s, Abrasive grit size: 50–200 µm, Flow pressure: 10–50 bar | Closed impellers, aerospace pumps |

| Shot Peening/Blasting | High-velocity shot balls impact surface | Shot size: 0.2–1.0 mm, Velocity: 50–100 m/s, Impact angle: 45°–90° | Zinc hydrometallurgy, slurry pumps |

| Coating/Plating | Application of metal or ceramic layer | Coating thickness: 10–100 µm, Temperature: 320–390°C (for galvanic coatings) | Chemical processing, marine pumps |

| 아노다이징 | Electrolytic formation of oxide layer | Voltage: 12–20 V, Acid concentration: 10–20% sulfuric acid, Time: 20–60 min | Aluminum impellers, wastewater treatment |

Effects of Surface Treatments on Impeller Performance

Surface treatments directly influence impeller performance metrics such as hydraulic efficiency, cavitation resistance, and service life. Below, we analyze these effects in detail.

Hydraulic Efficiency

Surface roughness significantly impacts hydraulic efficiency. Studies show that reducing surface roughness from Ra 1.6 µm to Ra 0.4 µm can improve pump efficiency by up to 4.75%, as smoother surfaces reduce friction losses. For instance, AFM-treated closed impellers exhibit lower energy consumption due to improved flow dynamics. Numerical simulations using Computational Fluid Dynamics (CFD) confirm that lower roughness enhances pressure distribution and reduces disk friction losses.

Cavitation Resistance

Cavitation, caused by rapid pressure changes in the fluid, can erode impeller surfaces. Surface treatments like shot peening and hard anodizing increase surface hardness and compressive stress, reducing cavitation damage. For example, superhydrophilic coatings with SiO₂ nanoparticles (15–20 nm, 0.5% volumetric concentration) have been shown to mitigate cavitation effects, though superhydrophobic coatings may reduce pump head under certain conditions.

Corrosion and Wear Resistance

In aggressive environments, such as those involving slurries or acidic fluids, coatings like zinc phosphate or nickel plating enhance corrosion resistance. For instance, duplex stainless steel impellers with balanced austenite/ferrite ratios (affected by nitrogen content) exhibit superior corrosive wear resistance in zinc hydrometallurgy processes. The failure analysis of such impellers indicates that improper material composition can reduce service life from an expected 3 months to just 28 days.

Fatigue Strength and Durability

Shot peening induces compressive residual stresses, improving fatigue strength by up to 20% in cyclic loading conditions. This is particularly beneficial for impellers in high-vibration environments, such as slurry pumps. Additionally, treatments like AFM ensure dimensional accuracy, critical for maintaining performance in high-precision applications like aerospace.

Recent Advances and Research Insights

Recent studies highlight innovative approaches to impeller surface treatments. For instance, additive manufacturing (AM) combined with AFM has been explored for Inconel 625 impellers, achieving improved geometrical stability and roughness (Ra 0.2–0.8 µm). Computational models, such as CFD coupled with Discrete Element Method (DEM), have been used to optimize shot blasting parameters, ensuring uniform coverage and minimal residual stress. Additionally, research on superhydrophilic and superhydrophobic coatings indicates potential for tailoring surface wettability to specific fluid dynamics, enhancing pump performance in niche applications.

Comparison of Treatment Effectiveness

The table below compares the effectiveness of different surface treatments based on key performance metrics.

| Treatment Type | Efficiency Improvement | Cavitation Resistance | 내식성 | Fatigue Strength |

|---|---|---|---|---|

| Abrasive Flow Machining | Up to 4.75% | 보통 | 낮음 | 보통 |

| Shot Peening/Blasting | 2–3% | 높음 | 보통 | High (up to 20%) |

| Coating/Plating | 3–4% | 보통 | 높음 | 낮음 |

| 아노다이징 | 1–2% | 높음 | 높음 | 보통 |

결론

Impeller surface treatments, including AFM, shot peening, coating, and anodizing, play a pivotal role in enhancing performance metrics such as efficiency, cavitation resistance, and durability. By carefully selecting treatment types and optimizing process parameters, industries can achieve significant improvements in impeller longevity and operational efficiency. Ongoing research continues to refine these processes, with advancements in computational modeling and additive manufacturing paving the way for more precise and effective treatments.