Stainless steel impellers are critical components in industries such as automotive, aerospace, chemical processing, and pump manufacturing. Their complex geometries and demanding performance requirements necessitate precise machining and appropriate surface treatments. Sandblasting, a widely used surface finishing technique, is often considered for enhancing the surface properties of machined stainless steel impellers. This article explores the suitability of sandblasting for stainless steel impeller machining, delving into technical details, process parameters, benefits, challenges, and practical applications. The analysis is structured to provide a clear, systematic, and professional evaluation for engineers, manufacturers, and industry professionals.

Understanding Stainless Steel Impeller Machining

Stainless steel impellers are typically manufactured using precision CNC machining or investment casting followed by machining to achieve tight tolerances and complex geometries. These components are designed to handle fluids, gases, or viscous materials, requiring high corrosion resistance, durability, and mechanical strength. Common stainless steel grades used include 304, 316, and duplex alloys like SS2205, selected for their corrosion resistance and wear properties.

CNC machining processes for impellers include milling, turning, drilling, and grinding, often performed on 5-axis CNC machines to accommodate intricate vane shapes and curved surfaces. The machining process must ensure dimensional accuracy (tolerances as low as ±0.01 mm) and surface finish (Ra 0.8–3.2 μm) to meet performance standards. Post-machining, surface treatments like sandblasting, polishing, or coating are applied to enhance functionality and aesthetics.

Key considerations in impeller machining include:

- 재료 선택: Stainless steel grades like 316 (CF8M) offer excellent corrosion resistance for chemical and marine applications.

- Geometric Complexity: Impellers often feature curved vanes and tight tolerances, requiring advanced CNC programming.

- Surface Quality: Smooth surfaces reduce friction and wear, while specific roughness levels improve coating adhesion.

- Balancing: Dynamic balancing (ISO 21940 G6.3) is critical to minimize vibration in high-speed applications.

Sandblasting as a Surface Treatment for Stainless Steel Impellers

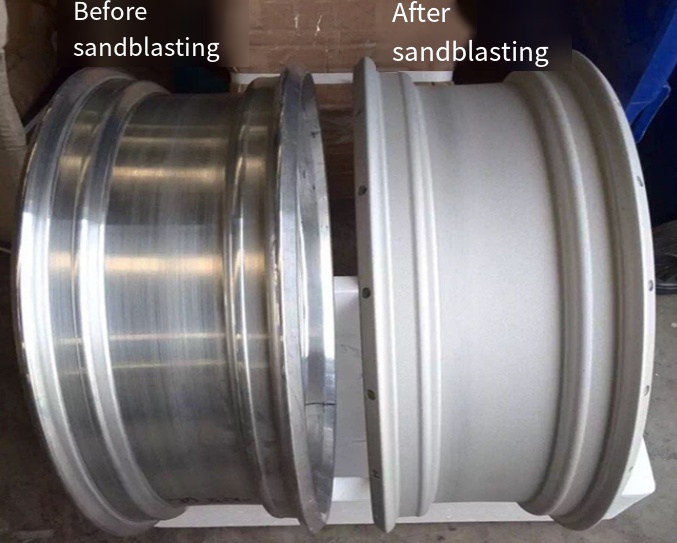

Sandblasting, also known as abrasive blasting, involves propelling abrasive media (e.g., glass beads, steel shot, or aluminum oxide) at high velocity using compressed air or centrifugal wheels to clean, texture, or modify a surface. For stainless steel impellers, sandblasting serves multiple purposes, including removing machining marks, deburring, improving surface uniformity, and preparing surfaces for coatings.

The suitability of sandblasting depends on the impeller’s application, material properties, and desired surface characteristics. Below, we explore the technical aspects of sandblasting for stainless steel impellers.

Technical Mechanism of Sandblasting

Sandblasting uses high-pressure air (typically 4–7 bar) or centrifugal impellers to propel abrasive particles (30–280 mesh) onto the workpiece surface. The impact removes surface contaminants, such as oxide scales, rust, or machining marks, and creates a uniform matte or satin finish. For stainless steel, common abrasives include glass beads for a smoother, brighter finish and white corundum for higher roughness.

The process parameters significantly affect the outcome:

| 매개변수 | 설명 | Typical Range |

|---|---|---|

| Abrasive Type | Glass beads, white corundum, steel shot | 30–280 mesh |

| 압력 | Compressed air pressure for blasting | 4–7 bar |

| Angle of Impact | Angle between abrasive stream and surface | 45–90° |

| Surface Roughness (Ra) | Resulting surface texture | 1.2–3.2 μm |

These parameters must be optimized to avoid excessive material removal or surface damage, particularly for precision components like impellers.

Benefits of Sandblasting for Stainless Steel Impellers

Sandblasting offers several advantages for stainless steel impellers, making it a preferred surface treatment in many applications:

- Surface Cleaning: Effectively removes oxide scales, machining marks, and contaminants, ensuring a clean surface for subsequent coatings or operational use.

- Improved Coating Adhesion: Creates a uniform, micro-rough surface (Ra 1.2–3.2 μm) that enhances the bonding of paints, anodizing, or PVD coatings.

- 디버링: Smooths out burrs and sharp edges from machining, improving safety and performance.

- Aesthetic Enhancement: Produces a consistent matte or satin finish, improving the visual appeal of the impeller.

- Mechanical Property Enhancement: Introduces compressive stress on the surface, potentially improving fatigue resistance.

For example, in pump manufacturing, sandblasted impellers exhibit better adhesion for anti-corrosion coatings, extending service life in harsh chemical environments.

Challenges and Limitations

While sandblasting is versatile, it has limitations that must be considered for stainless steel impellers:

- Risk of Surface Damage: Excessive pressure or abrasive size can cause micro-cracks or dimensional inaccuracies, particularly for thin-walled impellers.

- Material Removal: Over-blasting may alter critical tolerances, requiring post-treatment inspection.

- Dust and Contamination: The process generates dust, necessitating effective dust collection systems to maintain a clean work environment.

- Not Suitable for Mirror Finishes: Sandblasting produces a matte or satin finish, unsuitable for applications requiring high-gloss surfaces.

To mitigate these challenges, manufacturers must carefully control blasting parameters and use protective measures, such as masking critical areas like threaded holes.

Comparison with Other Surface Treatments

Sandblasting is one of several surface treatments available for stainless steel impellers. Comparing it with alternatives helps determine its suitability:

| Treatment | Purpose | 표면 마감(Ra) | 장점 | 단점 |

|---|---|---|---|---|

| 샌드 블라스팅 | Cleaning, texturing, coating prep | 1.2–3.2 μm | Uniform matte finish, cost-effective | Risk of over-blasting, dust generation |

| 전기 연마 | Polishing, deburring | 0.1–0.8 μm | Smooth, glossy finish, corrosion resistance | Higher cost, chemical handling |

| PVD Coating | Corrosion/wear protection | 0.8–1.6 μm | High durability, aesthetic appeal | Expensive, requires clean surface |

| 연마 | Aesthetic enhancement | 0.05–0.4 μm | Mirror-like finish | Time-consuming, labor-intensive |

Sandblasting is preferred when a uniform, matte finish and coating preparation are priorities, while electropolishing or polishing is better for applications requiring high-gloss surfaces.

Practical Applications of Sandblasted Stainless Steel Impellers

Sandblasted stainless steel impellers are used across various industries due to their enhanced surface properties:

- Pump Manufacturing: Sandblasting prepares impeller surfaces for anti-corrosion coatings, critical for chemical and marine pumps.

- 항공우주: Impellers in turbine engines benefit from sandblasting to remove machining marks and improve fatigue resistance.

- 자동차: Sandblasted impellers in turbochargers enhance coating adhesion for thermal barrier coatings.

- Medical Equipment: Sandblasting ensures clean, burr-free surfaces for impellers in medical pumps, meeting stringent hygiene standards.

A case study from a chemical plant in Spain demonstrated that a sandblasted stainless steel 316 impeller, fabricated via investment casting and CNC 가공, performed comparably to the original impeller in a centrifugal pump, handling viscous fluids (30–500 cSt) with no significant performance degradation.

Best Practices for Sandblasting Stainless Steel Impellers

To ensure optimal results, manufacturers should follow these best practices:

- Parameter Optimization: Use low pressures (1–3 bar) for delicate impellers and medium pressures (4–6 bar) for robust components.

- Abrasive Selection: Choose glass beads (30–280 mesh) for smoother finishes and white corundum for higher roughness.

- Pre-Cleaning: Degrease and dry impellers to prevent oil contamination of abrasive media.

- Protective Measures: Mask critical areas (e.g., threaded holes) to prevent damage during blasting.

- Post-Treatment Inspection: Verify dimensional tolerances and surface roughness using profilometers and CMMs.

Automated sandblasting systems with dust collection and media recycling enhance efficiency and environmental compliance.

결론

Sandblasting is a highly suitable surface treatment for stainless steel impellers, offering benefits like surface cleaning, improved coating adhesion, and aesthetic enhancement. However, its effectiveness depends on precise control of parameters like abrasive type, pressure, and impact angle. Compared to alternatives like electropolishing or PVD coating, sandblasting is cost-effective and versatile but requires careful application to avoid surface damage. By following best practices and tailoring the process to the impeller’s material and application, manufacturers can achieve high-quality, durable components for demanding industries like pump manufacturing, aerospace, and automotive.