Thermal deformation during impeller machining is a critical challenge in precision manufacturing, impacting dimensional accuracy and performance. This article explores systematic strategies to minimize thermal deformation, focusing on material selection, process optimization, cooling techniques, and advanced technologies. By addressing key factors with technical precision and detailed parameters, manufacturers can enhance impeller quality and efficiency.

Understanding Thermal Deformation in Impeller Machining

Thermal deformation occurs due to heat generated during machining processes like milling, turning, or grinding. The heat arises from friction between the tool and workpiece, cutting forces, and material properties. For impellers, which often feature complex geometries and thin blades, even minor deformations can lead to significant deviations from design specifications, affecting aerodynamic performance and structural integrity.

Key factors contributing to thermal deformation include:

- 머티리얼 속성: Thermal conductivity, coefficient of thermal expansion, and specific heat capacity influence how materials respond to heat.

- Machining Parameters: Cutting speed, feed rate, and depth of cut directly affect heat generation.

- 툴링: Tool material, geometry, and wear impact frictional heat.

- Coolant Efficiency: Inadequate cooling exacerbates heat accumulation.

- Machine Setup: Fixturing and clamping can induce stresses that amplify thermal effects.

Addressing these factors systematically ensures consistent quality in impeller production.

Material Selection for Minimizing Thermal Deformation

Choosing materials with favorable thermal properties is a foundational step in reducing deformation. Materials with high thermal conductivity dissipate heat efficiently, while those with low thermal expansion coefficients resist dimensional changes under temperature fluctuations.

| 재료 | Thermal Conductivity (W/m·K) | Coefficient of Thermal Expansion (µm/m·K) | Application Notes |

|---|---|---|---|

| Aluminum Alloys (e.g., 7075) | 130-150 | 23-24 | High conductivity, suitable for lightweight impellers |

| 티타늄 합금(예: Ti-6Al-4V) | 6.7-7.5 | 8.6-9.0 | Low expansion, ideal for high-temperature environments |

| Stainless Steel (e.g., 316) | 15-16 | 16-18 | Moderate properties, used in corrosion-resistant impellers |

For impellers, 티타늄 합금 are often preferred in aerospace applications due to their low thermal expansion, despite lower conductivity. Aluminum alloys suit less demanding applications where weight is a concern. Material selection should align with the impeller’s operating environment and machining constraints.

Optimizing Machining Parameters

Machining parameters significantly influence heat generation. Optimizing these parameters reduces thermal deformation while maintaining efficiency. Key parameters include:

- Cutting Speed (Vc): High speeds increase heat but improve surface finish. For titanium alloys, Vc of 50-80 m/min is recommended to balance heat and productivity.

- Feed Rate (f): Lower feed rates (0.05-0.1 mm/rev for titanium) reduce heat but extend machining time.

- Depth of Cut (ap): Shallow cuts (0.5-1.5 mm) minimize heat input compared to deeper cuts.

High-speed machining (HSM) with controlled parameters can reduce thermal impact. For instance, using a cutting speed of 60 m/min, feed rate of 0.08 mm/rev, and depth of cut of 1 mm for Ti-6Al-4V impellers minimizes heat while ensuring precision. Adaptive control systems can dynamically adjust these parameters based on real-time temperature feedback.

Toolpath optimization also plays a role. Trochoidal milling, which uses circular tool paths, reduces heat buildup by minimizing tool-workpiece contact time. Studies indicate that trochoidal paths can reduce cutting temperatures by up to 20% compared to conventional linear paths.

Effective Cooling and Lubrication Strategies

Cooling and lubrication are critical for dissipating heat and reducing friction. Common methods include:

- Flood Cooling: Delivers a continuous coolant stream to the cutting zone. Effective for aluminum but less so for titanium due to its low conductivity.

- Minimum Quantity Lubrication (MQL): Uses a mist of oil and air, reducing coolant consumption while maintaining lubrication. MQL with vegetable-based oils at 10-50 ml/h is effective for stainless steel impellers.

- 극저온 냉각: Employs liquid nitrogen or CO2 at -195°C or -78°C, respectively, to rapidly cool the cutting zone. Cryogenic cooling can reduce temperatures by 30-40% compared to flood cooling.

Cryogenic cooling is particularly effective for titanium alloys, as it minimizes thermal gradients. For example, using liquid nitrogen at a flow rate of 0.5-1 L/min can maintain workpiece temperatures below 100°C during high-speed milling. However, MQL is more cost-effective for small-scale operations.

Tooling and Machine Setup Considerations

Tool material and geometry significantly affect heat generation. Carbide tools with coatings like TiAlN or AlCrN reduce friction and withstand high temperatures. For instance, TiAlN-coated tools maintain edge stability up to 800°C, suitable for titanium machining.

Tool geometry should include:

- Rake Angle: Positive rake angles (10-15°) reduce cutting forces and heat.

- 나선 각도: High helix angles (30-45°) improve chip evacuation, reducing heat buildup.

- Edge Radius: A radius of 20-30 µm balances sharpness and durability.

Fixturing also impacts thermal deformation. Vacuum chucks or modular fixtures minimize clamping stresses, which can exacerbate deformation. Ensuring uniform clamping pressure (e.g., 0.5-1 MPa) prevents localized stress concentrations.

Advanced Technologies for Thermal Management

Innovative technologies further reduce thermal deformation:

- Thermal Compensation Systems: CNC machines with thermal compensation adjust for temperature-induced expansions. For example, real-time monitoring with laser interferometry can correct positional errors within 0.01 mm.

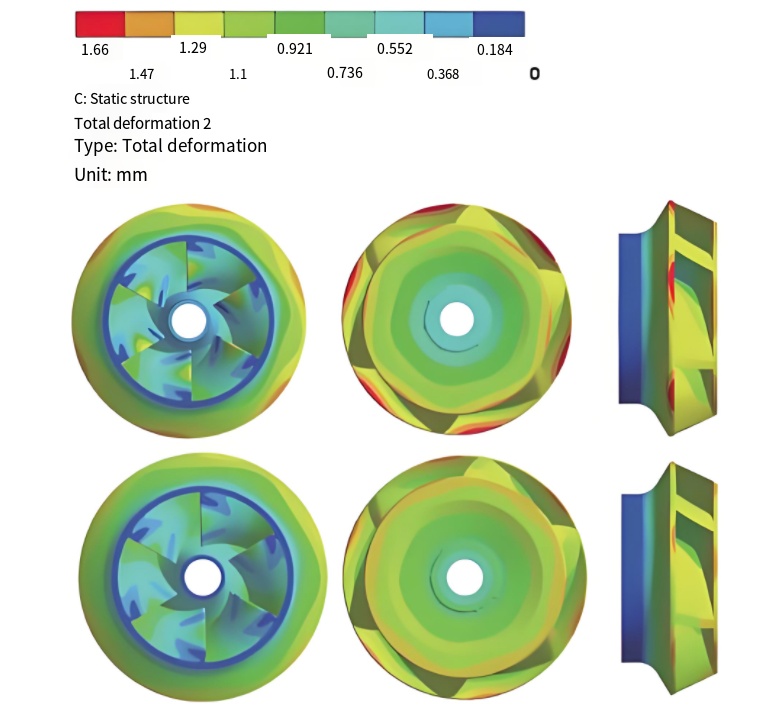

- Finite Element Analysis (FEA): Simulates thermal and mechanical stresses to predict deformation. FEA models can optimize toolpaths and parameters before machining.

- Additive-Hybrid Manufacturing: Combining additive manufacturing with subtractive machining reduces material removal, lowering heat input. For instance, near-net-shape impellers require 30% less machining, reducing thermal effects.

Integrating these technologies requires investment but yields significant improvements in precision and efficiency.

Case Study: Practical Implementation

A case study involving a Ti-6Al-4V impeller for aerospace applications illustrates these strategies. The machining process used:

| 매개변수 | Value | Outcome |

|---|---|---|

| 절단 속도 | 60m/분 | Reduced heat generation |

| 피드 속도 | 0.08 mm/rev | Minimized thermal gradients |

| Coolant | Cryogenic (LN2, 0.7 L/min) | Workpiece temperature < 100°C |

| Tool | TiAlN-coated carbide | Extended tool life by 25% |

The result was a dimensional accuracy within ±0.02 mm and no significant thermal deformation, meeting stringent aerospace tolerances.

결론

Reducing thermal deformation in impeller machining requires a multifaceted approach, integrating material selection, optimized parameters, effective cooling, advanced tooling, and innovative technologies. By implementing these strategies with precise parameters, manufacturers can achieve high precision and reliability. Continuous monitoring and adaptation to specific impeller requirements ensure optimal outcomes in demanding applications.