High-temperature alloys, such as nickel-based and titanium-based alloys, are widely used in impeller manufacturing for aerospace, power generation, and other high-performance applications due to their excellent strength, corrosion resistance, and heat tolerance. Machining these alloys presents significant challenges because of their high hardness, low thermal conductivity, and tendency to work-harden. The selection of an appropriate cutting fluid is critical to ensure efficient machining, prolong tool life, and maintain the quality of the machined impeller. This article provides a comprehensive guide on how to choose cutting fluids for high-temperature alloy impeller machining, focusing on technical requirements, material properties, and practical considerations.

Understanding High-Temperature Alloys and Impeller Machining

High-temperature alloys, often referred to as superalloys, include materials like Inconel, Hastelloy, and titanium alloys. These materials are designed to withstand extreme conditions, making them ideal for impellers in turbine engines and other high-stress environments. However, their properties—such as high strength, heat resistance, and low thermal conductivity—make machining difficult. Impellers, with their complex geometries and thin blades, require precise machining to achieve tight tolerances and smooth surface finishes. The primary functions of cutting fluids in this context are to cool the cutting zone, reduce friction, remove chips, and prevent tool wear.

Key material properties affecting machining include:

- High Hardness: Nickel-based alloys like Inconel 718 have hardness values ranging from 40 to 48 HRC, increasing tool wear.

- Low Thermal Conductivity: Titanium alloys have thermal conductivity as low as 6-7 W/m·K, causing heat buildup in the cutting zone.

- Work Hardening: These alloys harden during machining, increasing cutting forces and tool stress.

- Chemical Reactivity: Some alloys react with tool materials at high temperatures, leading to adhesion and wear.

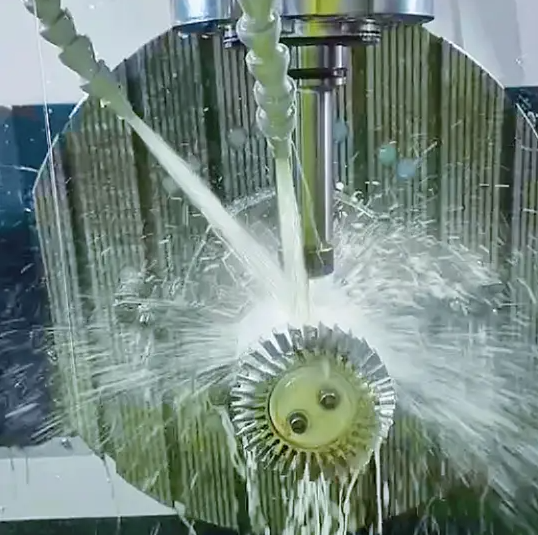

Impeller machining typically involves processes like milling, turning, and drilling, often performed on 5-axis CNC machines to handle complex contours. The choice of cutting fluid must address the heat generated, lubricate the tool-workpiece interface, and ensure efficient chip evacuation to maintain dimensional accuracy and surface quality.

Types of Cutting Fluids for High-Temperature Alloy Machining

Cutting fluids are broadly classified into several types based on their composition and application method. Each type has specific properties that make it suitable for machining high-temperature alloys. The main categories relevant to impeller machining are described below.

Neat Oils

Neat oils, also known as straight oils, are mineral or vegetable-based oils without water content. They provide excellent lubricity, making them suitable for low-speed, high-pressure operations like broaching or threading. For high-temperature alloys, neat oils with extreme pressure (EP) additives—such as sulfur, chlorine, or phosphorus compounds—are preferred. These additives form low-shear-strength films on the tool and workpiece, reducing friction and wear.

Application Parameters:

- Viscosity: 20-40 cSt at 40°C for optimal flow and lubrication.

- Flash Point: >200°C to prevent ignition during high-temperature machining.

- EP Additive Content: 5-10% sulfur or chlorine-based additives for nickel alloys.

Neat oils are less effective at cooling compared to water-based fluids, which can be a limitation in high-speed milling of impellers. They are best suited for operations requiring high lubrication, such as finishing passes on nickel-based alloys.

Soluble Oils

Soluble oils are emulsions of mineral oil and water, typically mixed at a ratio of 1:20 to 1:30 (oil to water). They offer a balance of cooling and lubrication, making them versatile for CNC milling and turning of impellers. Soluble oils are effective for titanium alloys, where cooling is critical due to low thermal conductivity.

Application Parameters:

- Concentration: 5-10% for general machining; 10-15% for heavy-duty operations.

- pH: 8.0-9.0 to prevent corrosion and maintain stability.

- Water Hardness: <200 ppm to avoid foaming and ensure emulsion stability.

Soluble oils require careful monitoring of dilution ratios and water quality to prevent bacterial growth and corrosion, which can affect impeller surface quality.

Synthetic and Semi-Synthetic Fluids

Synthetic fluids are water-based solutions containing no mineral oil, offering excellent cooling and corrosion resistance. Semi-synthetic fluids combine synthetic compounds with small amounts of oil, providing a balance of cooling and lubricity. These fluids are ideal for high-speed machining of high-temperature alloys, such as milling titanium impellers.

Application Parameters:

- Concentration: 3-7% for synthetics; 5-10% for semi-synthetics.

- Thermal Conductivity: >0.5 W/m·K for effective heat dissipation.

- EP Additives: Phosphorus-based for titanium; sulfur-based for nickel alloys.

Synthetic fluids are preferred for their stability at high temperatures and ability to maintain low cutting zone temperatures, which is critical for preventing thermal deformation in impeller blades.

Minimum Quantity Lubrication (MQL)

MQL involves applying a small amount of lubricant (50-500 ml/h) as an aerosol, targeting the cutting zone. This method is effective for reducing heat generation and improving chip evacuation in high-temperature alloy machining. Vegetable-based MQL fluids are environmentally friendly and suitable for nickel alloys.

Application Parameters:

- Flow Rate: 100-300 ml/h for milling; 50-150 ml/h for drilling.

- Pressure: 4-6 bar for precise delivery.

- Lubricant Type: Vegetable-based oils with EP additives for nickel alloys.

MQL is less effective at cooling but excels in reducing friction, making it suitable for semi-finishing and finishing operations on impellers.

Selection Criteria for Cutting Fluids

Choosing the right cutting fluid for high-temperature alloy impeller machining requires a systematic evaluation of several factors. The following criteria are essential for ensuring optimal performance.

재료 호환성

The cutting fluid must be compatible with the specific alloy being machined. For nickel-based alloys like Inconel 718, fluids with sulfur-based EP additives are effective but should be avoided for titanium alloys due to potential embrittlement. Titanium alloys benefit from chlorine-free, water-based fluids with high cooling capacity.

| Alloy Type | Recommended Fluid | Additives | Considerations |

|---|---|---|---|

| Nickel-Based (e.g., Inconel 718) | Neat Oil, Semi-Synthetic | Sulfur, Phosphorus | Avoid sulfur with carbide tools at high speeds |

| Titanium-Based (e.g., Ti-6Al-4V) | Synthetic, Soluble Oil | Chlorine-Free | High cooling capacity required |

가공 프로세스

The machining process dictates the fluid’s primary function. Milling impellers requires fluids with excellent cooling and chip removal properties due to complex tool paths. Drilling and turning benefit from fluids with high lubricity to reduce friction and prevent chip adhesion.

Process-Specific Recommendations:

- 밀링: Synthetic or semi-synthetic fluids with 5-10% concentration for cooling and chip evacuation.

- 선회: Soluble oils with 10-15% concentration for lubrication and heat dissipation.

- 드릴링: Low-viscosity synthetic fluids for chip removal in deep holes.

Tool Material and Coating

The cutting tool material (e.g., carbide, ceramic) and coating (e.g., TiC, TiN) influence fluid selection. Carbide tools are sensitive to sulfur-based fluids at high temperatures, which can cause embrittlement. Ceramic tools require water-based fluids to avoid thermal shock.

Tool-Specific Recommendations:

- Carbide Tools: Synthetic or semi-synthetic fluids with phosphorus-based additives.

- Ceramic Tools: Water-based synthetics with high thermal conductivity.

Environmental and Safety Considerations

Environmental regulations and operator safety are critical. Water-based fluids like synthetics and semi-synthetics are preferred for their low toxicity and biodegradability. Vegetable-based neat oils are an eco-friendly alternative but may produce odors during decomposition.

Key Parameters:

- pH: 8.0-9.0 to minimize skin irritation and corrosion.

- Biocide Content: <1% to prevent bacterial growth without compromising safety.

- Flash Point: >150°C for water-based fluids; >200°C for neat oils.

Application Methods and Delivery Systems

The effectiveness of a cutting fluid depends on its delivery method. Common methods for impeller machining include flooding, jet application, and MQL.

Flooding

Flooding involves delivering a high volume of fluid to the cutting zone, ideal for milling and turning. It ensures consistent cooling and chip removal but requires a robust coolant system.

매개변수:

- Flow Rate: 10-20 L/min for milling; 5-10 L/min for turning.

- Pressure: 1-2 bar for general applications.

Jet Application

Jet application uses high-pressure fluid delivery (4,000-7,000 psi) to break and flush chips, particularly in drilling deep holes in impellers. This method is effective for titanium alloys, where chip evacuation is critical.

매개변수:

- Pressure: 4,000-7,000 psi for titanium; 1,000-2,000 psi for nickel alloys.

- Nozzle Size: 0.5-1.0 mm for precise targeting.

Through-Spindle Delivery

Through-spindle systems deliver fluid directly through the tool, improving access to the cutting zone in deep-hole drilling and milling. This is particularly effective for impeller blade machining.

매개변수:

- Pressure: 1,000-3,000 psi for milling; 2,000-5,000 psi for drilling.

- Flow Rate: 5-15 L/min depending on tool size.

Practical Considerations for Implementation

To maximize the benefits of cutting fluids, consider the following practical aspects:

- Fluid Maintenance: Regularly monitor concentration, pH, and contamination using a refractometer. Maintain fluid sumps to prevent bacterial growth.

- Machine Compatibility: Ensure the CNC machine’s coolant system supports the chosen fluid type and delivery method.

- 비용 효율성: Balance fluid cost with performance. Synthetic fluids are more expensive but offer longer life and better cooling.

- Workpiece Cleaning: Water-based fluids are easier to clean than neat oils, reducing post-machining processing time.

| Fluid Type | 장점 | 단점 | Best Application |

|---|---|---|---|

| Neat Oil | High lubricity, rust protection | Poor cooling, difficult to clean | Low-speed, high-pressure operations |

| Soluble Oil | Balanced cooling and lubrication | Requires water quality control | General milling and turning |

| Synthetic | Excellent cooling, corrosion resistance | 더 높은 비용 | High-speed milling, titanium alloys |

| MQL | Low fluid consumption, eco-friendly | Limited cooling | Finishing, nickel alloys |

결론

Selecting the appropriate cutting fluid for high-temperature alloy impeller machining requires a thorough understanding of the alloy’s properties, the machining process, and the tool material. Neat oils, soluble oils, synthetic fluids, and MQL each offer unique benefits, with the choice depending on the specific requirements of cooling, lubrication, and chip evacuation. By carefully evaluating material compatibility, process demands, and delivery methods, manufacturers can optimize machining efficiency, extend tool life, and achieve high-quality impeller surfaces. Proper fluid maintenance and machine compatibility further ensure consistent performance, making cutting fluid selection a critical factor in successful impeller machining.