An impeller is a rotating component used in pumps and compressors to transfer energy from a motor to a fluid, increasing its pressure and flow rate. It is a critical element in centrifugal pumps, compressors, and other turbomachinery, converting mechanical energy into fluid kinetic energy. Impellers are designed to optimize fluid dynamics, enhance efficiency, and ensure durability under various operating conditions. This article provides a detailed overview of impellers, their types, key design parameters, and applications, supported by technical data and structured for clarity.

Definition of an Impeller

An impeller is a rotor that accelerates fluid outward from its center of rotation, generating pressure and flow within a pump or compressor. Unlike a turbine, which extracts energy from a fluid, an impeller imparts energy to it. Typically, impellers feature vanes arranged around a central shaft, with fluid entering axially through an inlet (called the "eye") and exiting radially or axially, depending on the design. Impellers are integral to devices like centrifugal pumps, agitation tanks, and compressors, where they facilitate fluid movement in specific directions.

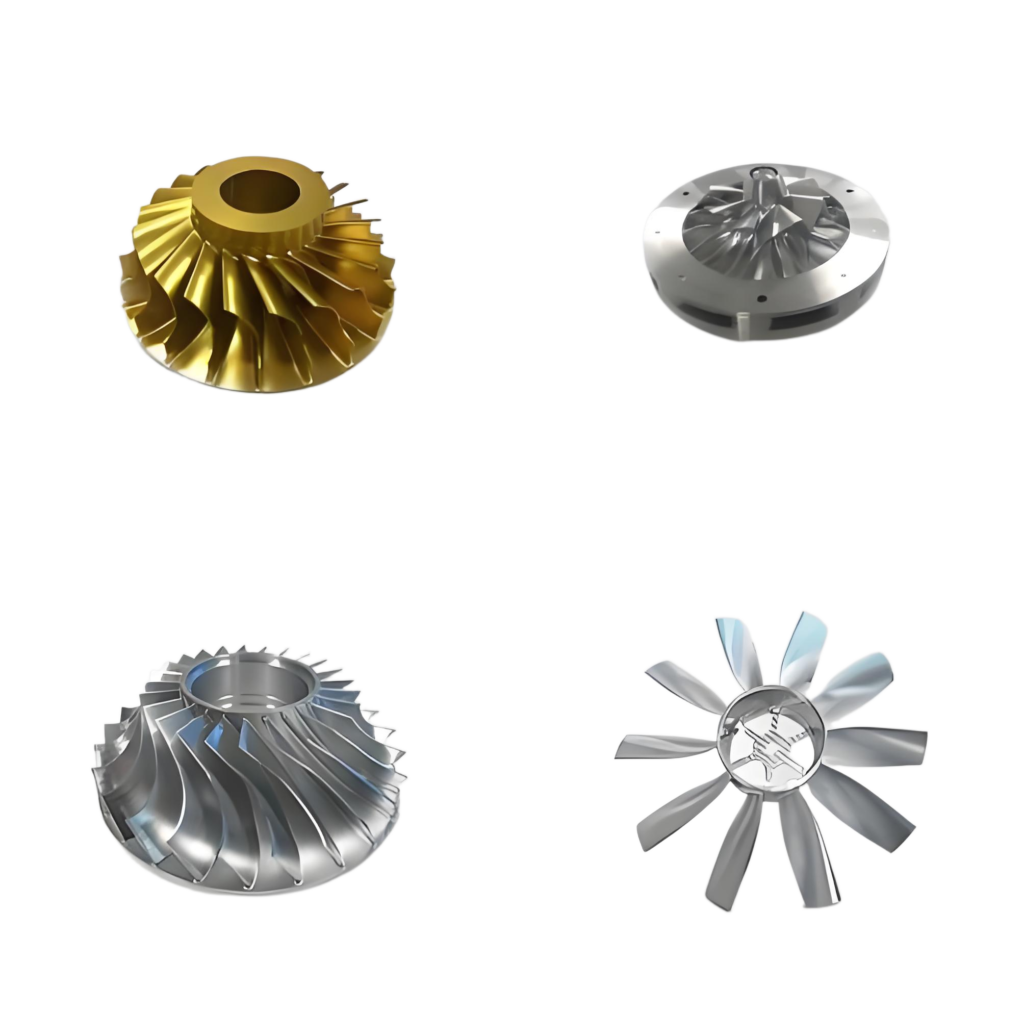

Types of Impellers

Impellers are classified based on their design and flow characteristics. The main types include open, semi-open, closed, and specialized designs like vortex and cutter impellers. Each type is suited to specific applications, balancing efficiency, strength, and solid-handling capabilities.

| Impeller Type | 설명 | 애플리케이션 | 장점 | 단점 |

|---|---|---|---|---|

| Open | Vanes attached to a hub without shrouds, open on both sides. | Small pumps, handling suspended solids. | Easy to inspect, maintain, and modify; suitable for solids. | Lower strength, higher NPSH required, less efficient. |

| Semi-Open | Vanes with a back shroud, open on the inlet side. | Medium-sized pumps with small amounts of soft solids. | Improved strength over open impellers, moderate efficiency. | Requires tight vane-casing clearance, moderate solid handling. |

| Closed | Vanes enclosed by shrouds on both sides. | Large pumps for clean liquids. | High efficiency, low NPSH, strong structure. | Complex design, higher maintenance due to wear rings. |

| Vortex | Non-channel impeller creating a whirlpool effect. | Dirty fluids with debris or stringy solids. | Excellent solid handling, low clogging risk. | Lower efficiency, not ideal for clean liquids. |

| Cutter | Sharp-edged vanes to grind solids before pumping. | Sewage, wastewater with solids. | Handles tough solids by cutting them. | Lower efficiency, specialized use. |

Key Design Parameters

Impeller performance depends on several geometric and operational parameters. These factors influence head, flow rate, efficiency, and durability. The following table summarizes critical parameters and their impact.

| 매개변수 | 설명 | Impact on Performance |

|---|---|---|

| Impeller Diameter | Size of the impeller, affecting head and flow rate. | Larger diameters increase head and flow but raise energy consumption (H ∝ D²). |

| Blade Angle | Inlet (β₁) and outlet (β₂) angles of vanes. | Optimized angles reduce turbulence and enhance energy transfer efficiency. |

| Number of Blades | Total count of vanes on the impeller. | More blades improve efficiency but increase manufacturing complexity. |

| Blade Shape | Curvature and profile of vanes (e.g., radial, axial, mixed). | Curved blades reduce turbulence, improving efficiency for specific flow types. |

| Impeller Width | Width of the impeller affecting flow capacity. | Wider impellers handle higher flow rates but may increase friction losses. |

| 재료 | Construction material (e.g., stainless steel, bronze, plastic). | Affects durability, corrosion resistance, and suitability for specific fluids. |

| 표면 마감 | Smoothness of impeller surfaces. | Smoother finishes reduce friction and turbulence, enhancing efficiency. |

| Rotation Speed | Speed of impeller rotation (RPM). | Higher speeds increase flow and pressure but may cause cavitation or wear. |

Operational Characteristics

Impellers operate by accelerating fluid outward, creating a pressure differential that drives flow. Key operational aspects include:

- Flow Coefficient: Describes volumetric flow as a function of tip diameter and speed. Lower coefficients suit 2D shrouded impellers, while higher coefficients require 3D or axial-flow designs.

- Pressure Pulsation: At high rotation speeds (e.g., 45,000 RPM), blade passing frequency (BPF) generates noise signals, with dominant frequencies like 5.25 kHz (half BPF) and 10.5 kHz (BPF).

- 효율성: Efficiency increases with flow coefficient but may decrease with wider impellers due to friction losses. Closed impellers typically offer higher efficiency than open designs.

- Cavitation: High-speed impellers risk cavitation, requiring careful inlet sizing and net positive suction head (NPSH) calculations to prevent performance degradation.

Applications of Impellers

Impellers are used across industries for fluid movement and pressure generation. Common applications include:

- Centrifugal Pumps: Used in water supply, wastewater treatment, and oil and gas industries to move liquids.

- Compressors: Employed in HVAC systems, refrigeration, and industrial gas processing.

- Agitation Tanks: Facilitate mixing in chemical processing, bioreactors, and fermentation tanks.

- Turbomolecular Pumps: Used in high-vacuum systems, such as semiconductor manufacturing and scientific research, to achieve ultra-low pressures by accelerating gas molecules toward exhaust stages.

- Washing Machines: Drive water movement for cleaning cycles.

- Specialized Systems: Vortex impellers handle sewage, while cutter impellers process solid-laden wastewater.

Design and Simulation Tools

Modern impeller design leverages computational fluid dynamics (CFD) and computer-aided design (CAD) tools to optimize performance. Tools like ANSYS CFX, FLUENT, and SolidWorks enable engineers to:

- Simulate fluid flow, pressure distribution, and cavitation effects.

- Model impeller geometry using software like BLADEGEN and TURBOGRID for precise meshing.

- Analyze stress and deformation under various operating conditions.

- Optimize parameters like blade angle, number, and diameter for specific applications.

These tools reduce design time, improve accuracy, and allow for virtual prototyping, minimizing costly physical iterations.

Challenges in Impeller Design

Designing efficient impellers involves addressing several challenges:

- Cavitation: High-speed rotation can cause vapor bubble formation, reducing efficiency and causing damage.

- 착용: In slurry pumps, abrasive particles can erode impeller surfaces, necessitating robust materials.

- Efficiency Losses: Improper blade angles or clearances can lead to turbulence and reduced performance.

- Manufacturing Complexity: Closed impellers require precise fabrication, increasing costs.

Advanced materials, surface coatings, and optimized geometries help mitigate these issues.

결론

Impellers are essential components in fluid-handling systems, with their performance governed by design parameters like diameter, blade angle, and material selection. By understanding impeller types, operational characteristics, and design challenges, engineers can optimize efficiency and durability for specific applications. CFD and CAD tools further enhance design precision, making impellers critical to industries ranging from water management to chemical processing.