Precision impeller machining requires advanced programming software to achieve high accuracy, efficiency, and repeatability in manufacturing complex geometries. Impellers, critical components in turbomachinery such as compressors, turbines, and pumps, demand sophisticated CAD/CAM solutions to handle intricate blade surfaces, hub geometries, and multi-axis machining requirements. This article explores the leading programming software used for precision impeller machining, focusing on their technical capabilities, key features, and specific applications in impeller production. The content is structured to provide a clear, systematic overview for professionals seeking reliable tools for impeller manufacturing.

Overview of CAD/CAM Software for Impeller Machining

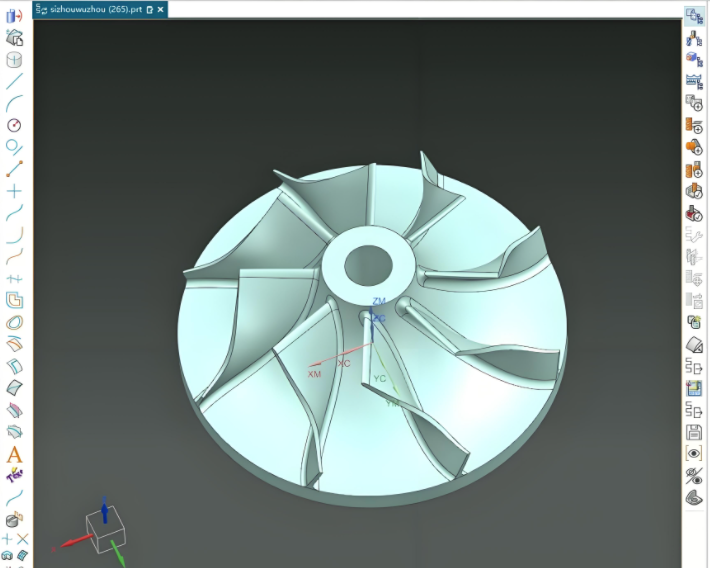

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are integral to impeller machining. CAD software enables the creation of detailed 3D models of impellers, defining blade surfaces, hub profiles, and geometric tolerances. CAM software translates these models into toolpaths and G-code, controlling CNC machines to execute precise cuts. For impellers, which often feature complex free-form surfaces and require 5축 가공, the software must support advanced toolpath generation, collision detection, and simulation capabilities. The following sections detail the most effective software solutions, their functionalities, and their suitability for impeller machining.

Key Software Solutions for Impeller Machining

Several CAD/CAM software packages are widely used for precision impeller machining, each offering specialized features tailored to the demands of turbomachinery components. Below is an in-depth analysis of the top software solutions, including their technical specifications and applications.

Mastercam

Mastercam is a leading CAM software known for its comprehensive toolpath generation capabilities. It supports 2D, 3D, and multi-axis machining, making it suitable for impeller production in industries such as aerospace and automotive. Its Multiaxis module includes specialized toolpaths for impellers, such as blade and hub machining strategies.

- Toolpath Generation: Supports 5-axis simultaneous machining with options for swarf milling, flank milling, and point-to-point machining. Blade machining toolpaths ensure smooth transitions between hub and shroud surfaces.

- Simulation: Includes verification tools to simulate toolpaths and detect collisions, reducing errors during machining.

- Technical Specifications: Compatible with Windows OS, supports G-code for Fanuc, Siemens, and Heidenhain controllers, and integrates with CAD platforms like SolidWorks and CATIA.

- 애플리케이션: Used for milling impellers in aluminum, titanium, and stainless steel, with support for diameters ranging from 0.2 inches to over 73 inches.

Mastercam’s extensive tool library and customizable post-processors make it a versatile choice for precision impeller machining, particularly for complex geometries requiring high surface finish quality.

Autodesk PowerMill

Autodesk PowerMill is a high-performance CAM software optimized for multi-axis machining. Its advanced toolpath strategies and simulation capabilities make it ideal for impeller production, especially for high-precision components in aerospace and energy sectors.

- Toolpath Generation: Offers specialized impeller and blisk machining strategies, including 5-axis contouring and adaptive clearing for efficient material removal. Toolpaths can be optimized for barrel cutters and toroidal tools.

- Simulation: Provides kinematic simulation to prevent collisions on 5-axis machines, with support for NC code verification.

- Technical Specifications: Supports 3-axis to 5-axis machining, compatible with Windows, and integrates with Autodesk Fusion for seamless CAD/CAM workflows. Maximum feed rate support up to 20 m/min for high-speed machining.

- 애플리케이션: Suitable for machining impellers with complex blade profiles, including shrouded and open impellers, in materials like Inconel and titanium.

PowerMill’s ability to handle intricate surfaces and optimize toolpaths for minimal machining time makes it a preferred choice for high-volume impeller production.

Siemens NX

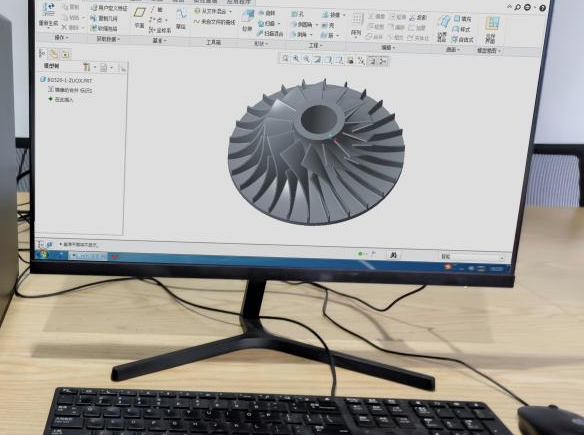

Siemens NX is a robust CAD/CAM platform with a dedicated impeller machining module. Its integrated environment supports design, simulation, and manufacturing, making it suitable for complex impeller geometries.

- Toolpath Generation: Features a specialized impeller programming module for 5-axis machining, supporting flank milling and variable contour strategies. Toolpaths are optimized for blade and hub surfaces with varying radii.

- Simulation: Uses VERICUT integration for NC code simulation, ensuring accurate toolpath execution.

- Technical Specifications: Supports Windows OS, compatible with multi-axis CNC machines, and handles impeller diameters up to 1854 mm. G-code output is customizable for various controllers.

- 애플리케이션: Widely used in the mold industry and for machining impellers in jet engines and centrifugal compressors.

Siemens NX’s rich tutorial resources and robust post-processing capabilities make it accessible for both beginners and professionals working on impeller machining.

hyperMILL by OPEN MIND

hyperMILL is a high-end CAM software with a dedicated Multiblade package for impeller and blisk machining. Its automated functions simplify programming while ensuring process reliability.

- Toolpath Generation: The Multiblade package supports flank milling for blade surfaces and hub machining, with automatic tool nesting for optimal positioning. Feed rates can reach up to 15 m/min for high-efficiency machining.

- Simulation: Uses NC code-based simulation (VIRTUAL Machining) for precise movement validation, minimizing collision risks.

- Technical Specifications: Compatible with Windows, supports 5-axis milling, and integrates with CAD systems like CATIA and SolidWorks. Maximum infeed parameters up to 5 mm for roughing.

- 애플리케이션: Ideal for aluminum impeller machining on machines like DMG MORI DMU 65 monoBLOCK, ensuring high surface quality.

hyperMILL’s focus on automation and collision checking makes it a reliable choice for machining impellers with complex geometries and tight tolerances.

DELMIA Machining by Dassault Systèmes

DELMIA Machining is an advanced CAM software that integrates 3D modeling and simulation for optimized CNC programming. It is designed for complex, high-precision parts like impellers.

- Toolpath Generation: Supports milling, turning, and multi-axis machining with automated toolpath generation. Templates reduce programming time by up to 80%.

- Simulation: Provides realistic 3D simulation of tool assembly and toolpaths, detecting errors before machining.

- Technical Specifications: Compatible with Windows, supports G-code for various CNC controllers, and handles complex geometries with true position accuracy of 0.03 mm.

- 애플리케이션: Used for aerospace components and turbine impellers, supporting materials like stainless steel and exotic alloys.

DELMIA’s automation and simulation capabilities streamline the production of impellers, improving precision and reducing lead times.

Comparison of Software Features

The following table compares the key features of the discussed software solutions, focusing on their suitability for impeller machining.

| Software | 다중 축 지원 | Specialized Impeller Module | Simulation Type | 재료 호환성 | Max Impeller Diameter |

|---|---|---|---|---|---|

| Mastercam | 3-5 axis | Yes (Multiaxis) | Toolpath verification | Aluminum, Titanium, Stainless Steel | 73 inches |

| Autodesk PowerMill | 3-5 axis | Yes (Impeller/Blisk) | Kinematic simulation | Inconel, Titanium, Aluminum | Variable |

| Siemens NX | 3-5 axis | Yes (Impeller Module) | VERICUT NC simulation | Aluminum, Stainless Steel, Exotics | 1854 mm |

| hyperMILL | 3-5 axis | Yes (Multiblade) | NC code-based | Aluminum, Titanium | Variable |

| DELMIA Machining | 3-5 axis | No (General Multi-Axis) | 3D simulation | Stainless Steel, Exotic Alloys | Variable |

Technical Considerations for Impeller Machining

Impeller machining involves several technical considerations that influence software selection. These include the complexity of impeller geometry, material properties, and CNC machine capabilities.

- Geometry Complexity: Impellers feature free-form surfaces, including camber, suction, and pressure surfaces. Software must support surface modeling and precise toolpath generation to maintain tolerances as tight as 0.03 mm.

- 머티리얼 속성: Impellers are often made from challenging materials like titanium or Inconel, requiring software with robust toolpath strategies to minimize tool wear and ensure surface quality.

- Machine Compatibility: Software must generate G-code compatible with specific CNC controllers (e.g., Fanuc, Siemens) and support 5-axis machines for complex impeller profiles.

- Simulation and Verification: Accurate simulation reduces errors, especially for 5-axis machining, where collisions can damage expensive tools or workpieces.

Selecting software that aligns with these considerations ensures efficient and precise impeller production.

Implementation Process for Impeller Machining

The implementation of CAD/CAM software for impeller machining follows a structured process to ensure accuracy and efficiency.

- CAD Model Creation: Use CAD software to create a 3D model of the impeller, defining blade and hub surfaces. Reverse engineering may be used to digitize existing impellers.

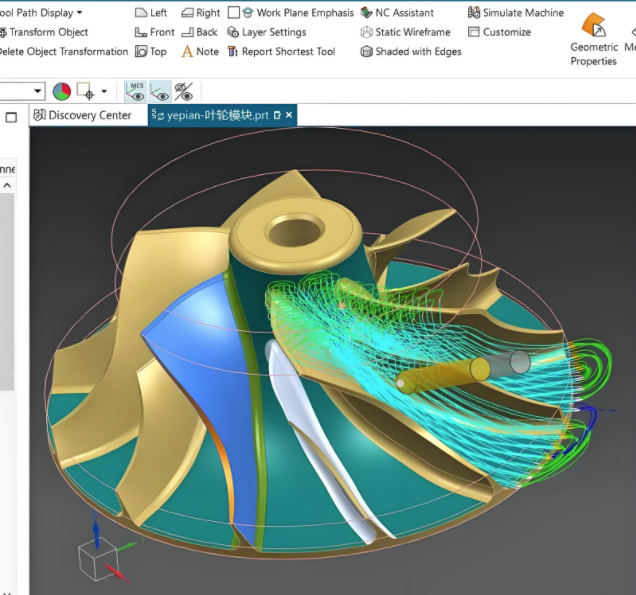

- Toolpath Planning: Import the CAD model into CAM software to generate toolpaths. Select strategies like flank milling or swarf cutting based on geometry.

- Simulation: Run simulations to verify toolpaths, checking for collisions and optimizing feed rates and cutting parameters.

- G-Code Generation: Convert toolpaths into G-code tailored to the CNC machine’s controller.

- Machining: Load the G-code into the CNC machine, fixture the stock material (typically a cylindrical bar), and execute the machining process.

This process ensures a seamless transition from design to finished impeller, minimizing errors and production time.

결론

Precision impeller machining relies on advanced CAD/CAM software to achieve high accuracy and efficiency. Mastercam, Autodesk PowerMill, Siemens NX, hyperMILL, and DELMIA Machining are among the top solutions, each offering specialized features for impeller production. By supporting multi-axis machining, precise toolpath generation, and robust simulation, these tools address the complexities of impeller geometries and materials. The choice of software depends on specific project requirements, including impeller size, material, and CNC machine capabilities. By understanding the technical specifications and applications of these software solutions, manufacturers can optimize their impeller machining processes for consistent, high-quality results.