Metal cutting machines are specialized equipment designed to shape and sever metal materials with high accuracy and efficiency. These devices play a critical role in industries such as manufacturing, construction, automotive, and aerospace, where precise metal components are required. The core function involves removing material from metal workpieces to achieve desired dimensions and forms. Various technologies power these machines, including thermal, mechanical, and abrasive methods, each suited to specific material types, thicknesses, and production volumes.

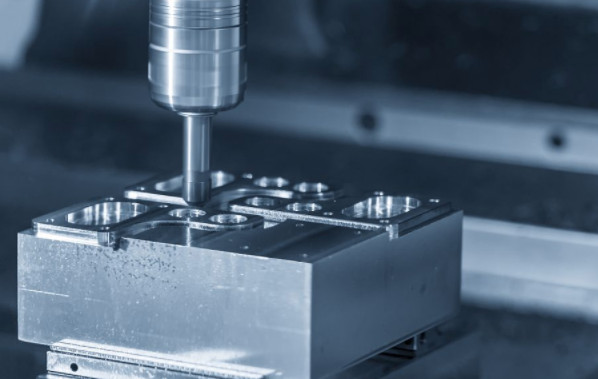

Understanding the fundamentals of metal cutting machines requires examining their components, which typically include a power source, cutting tool or head, control system, and workpiece holding mechanism. For instance, in computer numerical control (CNC) variants, software directs the cutting path, ensuring repeatability within tolerances as low as 0.001 inches. Power ratings range from 1 kW for small-scale units to over 20 kW for industrial models, directly influencing cutting speed and material thickness capacity.

Key parameters to consider include cutting speed, measured in inches per minute (IPM), feed rate, and kerf width—the width of the material removed during the cut, often between 0.005 and 0.25 inches depending on the method. Material compatibility extends to ferrous and non-ferrous metals like steel, aluminum, copper, and titanium, with hardness levels up to 60 HRC in some cases. Operational environments demand robust construction, often using cast iron bases for vibration dampening and longevity exceeding 10,000 hours of use.

Safety features integrate emergency stops, enclosures, and fume extraction systems, as metal cutting generates heat, sparks, and particles. Electrical requirements vary, with three-phase 220-480V supplies common for heavy-duty machines. Overall, these machines enhance productivity by reducing manual labor and minimizing waste through optimized nesting software that arranges parts on sheets to achieve up to 90% material utilization.

Types of Metal Cutting Machines

Metal cutting machines encompass a range of technologies, each optimized for particular applications based on factors like precision, speed, and cost. The primary categories include laser cutters, plasma cutters, waterjet cutters, and mechanical cutters. Laser cutters utilize focused light beams to melt or vaporize metal, offering exceptional detail. Plasma cutters employ ionized gas for rapid cuts on conductive materials. Waterjet systems use high-pressure water mixed with abrasives for cold cutting without heat-affected zones. Mechanical cutters rely on physical force, such as sawing or shearing, for straightforward operations.

Hybrid models combine elements, like CNC-integrated mechanical systems for automated precision. Portable variants exist for on-site work, weighing under 50 pounds, while stationary industrial units exceed 5,000 pounds. Control interfaces range from manual dials to touchscreen CNC panels supporting G-code programming. Cutting bed sizes vary from 2x2 feet for benchtop models to 10x20 feet for large-scale fabrication.

Energy consumption differs significantly: laser systems may require 10-50 kW, plasma 5-30 kW, waterjet 20-60 kW pumps, and mechanical under 5 kW. Maintenance intervals are typically every 500-1,000 hours, involving lens cleaning for lasers or nozzle replacement for plasma. Compatibility with automation, such as robotic arms, enhances throughput in high-volume settings.

| Type | Key Technology | Typical Cutting Thickness (inches) | Precision Tolerance (inches) | Common Applications |

|---|---|---|---|---|

| Laser Cutter | Focused beam | 0.01-1.0 | ±0.001 | Sheet metal, intricate parts |

| Plasma Cutter | Ionized gas | 0.125-2.0 | ±0.01 | Thick plates, structural steel |

| Waterjet Cutter | Abrasive water stream | 0.01-8.0 | ±0.005 | Composites, heat-sensitive metals |

| Mechanical Cutter | Blade or shear | 0.01-4.0 | ±0.02 | Bars, pipes, basic shapes |

Operational Principles and Technical Parameters

The operational principles of metal cutting machines hinge on energy transfer to separate metal atoms. In laser cutting, a coherent light beam, often CO2 or fiber-based with wavelengths of 10.6 μm or 1.06 μm, achieves power densities up to 10^6 W/cm², enabling vaporization. Parameters include beam diameter (0.1-0.5 mm), focal length (2-10 inches), and assist gas pressure (5-30 bar) using nitrogen or oxygen to eject molten material.

Plasma cutting involves an electrical arc through a gas like argon or air, heated to 20,000-30,000°C, with torch amperage from 20-400 A and voltage 100-200 V. Cutting speeds reach 100 IPM for 0.5-inch steel, with dross formation minimized via high-definition plasma at resolutions of 0.005 inches. Waterjet cutting pressurizes water to 60,000 psi through a 0.01-0.04 inch orifice, mixed with garnet abrasives at 0.5-1 lb/min, achieving velocities of 2,500 ft/s without thermal distortion.

Mechanical cutting uses shear stress exceeding the metal's ultimate tensile strength (e.g., 50-100 ksi for mild steel), with blade speeds of 50-500 ft/min and coolant flow rates of 1-5 gal/min to reduce friction. Detailed parameters across types include duty cycles (60-100%), noise levels (80-110 dB), and exhaust requirements (500-2,000 CFM). System integration often involves CAD/CAM software for path optimization, reducing cycle times by 20-30%.

Electrical efficiency varies: lasers at 10-30%, plasma 50-70%, waterjet 60-80%, mechanical 80-90%. Consumable lifespans are critical—laser resonators last 2,000-5,000 hours, plasma electrodes 1-2 hours per start, waterjet nozzles 50-100 hours, mechanical blades 100-500 cuts. Calibration procedures ensure alignment within 0.002 inches over 10 feet.

Applications in Various Industries

Metal cutting machines find extensive use across sectors requiring precise material processing. In automotive manufacturing, laser cutters fabricate body panels and engine components from aluminum sheets up to 0.25 inches thick, achieving tolerances of ±0.002 inches for seamless assembly. Plasma cutters handle chassis frames from 1-inch steel plates at speeds of 50 IPM, supporting high-volume production lines.

Aerospace applications demand waterjet cutters for titanium alloys up to 4 inches thick, preserving material integrity without heat-affected zones that could compromise strength (yield up to 160 ksi). Mechanical cutters process extruded profiles for aircraft structures, with shear forces up to 100 tons for clean edges.

Construction utilizes plasma systems for rebar and structural beams, cutting 2-inch diameters at 20 IPM. Shipbuilding employs large-format laser machines for hull plates, optimizing nesting to minimize waste from 20x60 foot sheets. Electronics industry relies on fine laser cutting for circuit board frames from 0.01-inch copper, with kerf widths under 0.05 mm.

Custom fabrication shops integrate CNC controls for prototypes, handling mixed materials like stainless steel (up to 1 inch) and brass. Parameters such as edge quality (Ra 50-200 μin) and burr height (<0.01 inches) ensure compliance with standards like ISO 9013 for cut quality classification from 1 to 5.

Selection Factors for Optimal Performance

Selecting a metal cutting machine involves evaluating technical specifications against operational needs. Material type dictates method: conductive metals suit plasma, while reflective ones like copper require fiber lasers with wavelengths under 1 μm. Thickness capacity is paramount—plasma for over 1 inch, laser for under 0.5 inches typically.

Precision requirements guide choices: waterjet for ±0.003 inches on thick stacks, mechanical for ±0.05 inches on bulk cuts. Production volume influences automation level—CNC for batches over 100, manual for one-offs. Budget considerations include initial costs ($5,000-$500,000) and operating expenses (consumables $0.10-$1 per foot cut).

Space constraints favor compact models under 10 square feet, while power availability limits high-amperage units. Software compatibility ensures seamless integration with design tools like AutoCAD, supporting file formats such as DXF and DWG. Vendor support for training and parts availability minimizes downtime to under 5% annually.

Environmental factors include ventilation for fumes (e.g., 1,000 CFM for plasma) and noise suppression. Scalability allows future upgrades, like adding rotary axes for tube cutting. Testing samples verifies performance, measuring cut speed, edge roughness, and dimensional accuracy.

| Parameter | Laser | Plasma | Waterjet | Mechanical |

|---|---|---|---|---|

| Max Power (kW) | 1-20 | 5-30 | 20-60 | 1-10 |

| Cutting Speed (IPM) | 10-500 | 20-200 | 1-50 | 5-100 |

| Setup Time (min) | 5-15 | 2-10 | 10-20 | 1-5 |

| Operating Cost ($/hr) | 10-50 | 5-20 | 15-40 | 2-10 |

Maintenance and Safety Protocols

Regular maintenance ensures longevity and consistent performance of metal cutting machines. Daily checks include inspecting optics or nozzles for debris, lubricating moving parts with ISO 32-68 oils, and verifying alignment using laser levels accurate to 0.001 inches per foot. Weekly tasks involve cleaning filters and calibrating sensors, while monthly overhauls replace wear items like belts (lifespan 1,000 hours) and bearings.

Safety protocols mandate personal protective equipment such as gloves rated ANSI cut level 5, eye protection with OD 5+ for lasers, and respirators for fumes exceeding 0.05 mg/m³ particulates. Machine guards prevent access to cutting zones, with interlocks halting operations if breached. Emergency shutdowns activate within 0.1 seconds, and fire suppression systems handle potential ignitions from sparks.

Training covers operational limits, like maximum loads (e.g., 500 lbs on tables) and prohibited materials to avoid explosions. Documentation logs usage hours, aiding predictive maintenance via software monitoring vibration (under 5 mm/s) and temperature (below 50°C for electronics). Compliance with standards like OSHA 1910.212 ensures risk mitigation.