Metal Computer Numerical Control (CNC) machining stands as a cornerstone of modern manufacturing, enabling the production of high-precision components with remarkable efficiency and scalability. Its impact is felt across virtually every major industry, from the stringent demands of aerospace and medical devices to the high-volume production of automotive and electronics parts. At its core, metal CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to selectively remove material from a solid block of metal, known as a workpiece or blank, to create a final part based on a digital design.

What is Metal CNC Machining? A Beginner’s Guide

To understand metal CNC machining, it is essential to first break down its core concepts and components. This technology represents a significant leap from traditional, manual machining methods, introducing automation and digital precision into the fabrication process.

Core Concept: Computer Numerical Control (CNC)

Computer Numerical Control (CNC) is the foundational technology that automates machine tools through pre-programmed computer commands. Instead of a human operator manually controlling the machine's movements, a computer directs the cutting tools according to a digital script. This script, known as G-code, contains precise instructions for every action, including tool speed, feed rate, and coordinate movements along multiple axes.

A Brief History

The evolution of machining began with purely manual lathes and mills, which required skilled operators to control every cut. The advent of numerical control (NC) in the mid-20th century introduced automation via punched tape systems. The integration of computers in the latter half of the century transformed NC into CNC, bringing greater flexibility, processing power, and the ability to execute highly complex designs flawlessly.

Key Components of the CNC Ecosystem

- CNC Machines: These are the workhorses of the process. Common types include CNC mills (where the tool rotates and the workpiece is stationary), CNC lathes (where the workpiece rotates against a stationary tool), and multi-axis machines that combine both operations for complex geometries.

- Software (CAD/CAM): The process begins with Computer-Aided Design (CAD) software, used to create a 2D or 3D digital model of the part. This model is then processed by Computer-Aided Manufacturing (CAM) software, which translates the design into G-code that the CNC machine can understand.

- Cutting Tools: A wide array of tools are used, each designed for a specific operation. These include drills for creating holes, end mills for cutting slots and profiles, and turning inserts for shaping cylindrical parts. Tools are often made from hardened steel, carbide, or diamond-coated materials to withstand the rigors of cutting metal.

Why Metal Demands CNC Machining

Unlike softer materials like wood or plastic, metals present unique challenges. Their hardness requires powerful, rigid machines and sharp, durable cutting tools. The process generates significant heat and force, which must be managed with coolants and precise control over cutting parameters. CNC machining provides the necessary rigidity, power, and automated control to cut metals with tolerances as fine as a few micrometers (μm), a level of accuracy impossible to achieve consistently by hand.

How Metal CNC Machining Works: Step-by-Step Process

The journey from a digital concept to a physical metal part follows a structured and highly controlled workflow. Each step is critical to ensuring the final component meets all design specifications.

- Design Phase (CAD): The process starts with a 2D vector or 3D solid part model created in CAD software. The design includes all geometric features, dimensions, and tolerances required for the part to function correctly.

- Programming Phase (CAM): The completed CAD file is imported into CAM software. Here, a manufacturing engineer or programmer develops the machining strategy. This involves selecting the appropriate machine, cutting tools, and toolpaths. The CAM software simulates the machining process to detect potential collisions and optimizes the toolpaths for efficiency and quality. The final output is the G-code file.

- Machine Setup: A skilled operator prepares the CNC machine. This involves securely fixturing the raw metal stock (the workpiece) onto the machine bed or chuck. The cutting tools are loaded into the machine's tool changer, and their precise lengths and diameters are measured. The operator then sets the machine's work coordinate system, which aligns the machine's starting point (0,0,0) with a specific point on the workpiece.

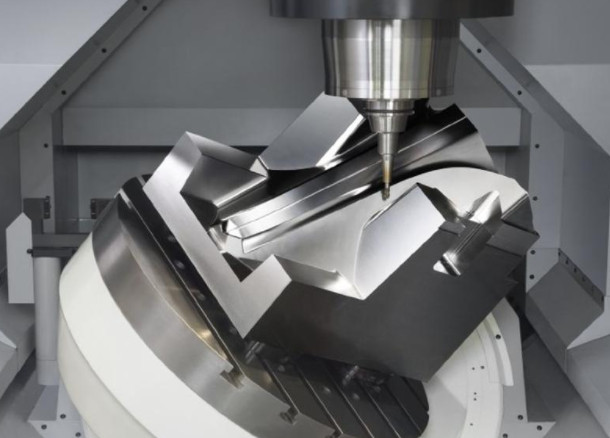

- Machining Execution: The G-code program is loaded into the CNC controller. The machine executes the code sequentially, automating the entire cutting process. It moves the cutting tool and/or workpiece along multiple axes (typically 3, 4, or 5 axes) to perform operations like milling, drilling, boring, and turning. A coolant fluid (such as a water-soluble oil) is often used to lubricate the cutting tool, prevent overheating, and flush away metal chips.

- Post-Processing: After the machining cycle is complete, the part is removed from the machine. It may require several finishing steps to meet final specifications. These can include deburring (removing small, sharp edges left by the cutting tool), polishing to achieve a smooth surface finish, or surface treatments like anodizing (for aluminum) or passivation (for stainless steel) to enhance corrosion resistance and appearance.

Common Metals Used in CNC Machining

The choice of metal is dictated by the part's intended application, including requirements for strength, weight, corrosion resistance, conductivity, and cost. Below are some of the most frequently used metals in CNC machining.

Ferrous Metals

Ferrous metals are alloys that contain iron as their primary component. They are known for their strength and durability.

- Steel: A broad category of iron-carbon alloys. Carbon steel is cost-effective and strong, used for structural parts and machinery. Stainless steel (e.g., grades 304, 316) contains chromium, providing excellent corrosion resistance, making it ideal for medical instruments and food-grade equipment.

- Iron: Cast iron is valued for its compressive strength and vibration-damping properties, often used for heavy machinery bases and engine blocks.

Non-Ferrous Metals

Non-ferrous metals do not contain significant amounts of iron and are chosen for properties like low weight, conductivity, and corrosion resistance.

- Aluminum: Lightweight, non-corrosive, and easy to machine. Grades like 6061-T6 offer a great balance of strength and machinability, while 7075 provides higher strength for demanding aerospace applications.

- Copper: Valued for its exceptional electrical and thermal conductivity. It is used for heat sinks, electrical connectors, and bus bars.

- Titanium: Known for its outstanding strength-to-weight ratio and biocompatibility. It is a premium material used extensively in aerospace for engine components and in the medical field for orthopedic implants.

Choosing the Right Metal

Selecting the appropriate metal involves a trade-off between material properties, cost, and manufacturability. Key factors include the operating environment, load-bearing requirements, weight constraints, and industry-specific standards (e.g., FDA requirements for medical devices).

| Metal | Key Properties | Common Applications |

|---|---|---|

| Aluminum (6061-T6) | Excellent strength-to-weight ratio, corrosion resistance, high machinability. | Aerospace components, automotive parts, consumer electronics enclosures. |

| Stainless Steel (304) | High corrosion resistance, good strength, weldable. | Food processing equipment, kitchen appliances, architectural fixtures. |

| Carbon Steel (1018) | High strength, good machinability, cost-effective. | Gears, shafts, structural parts, machine components. |

| Titanium (Grade 5) | Highest strength-to-weight ratio, excellent corrosion resistance, biocompatible. | Medical implants, aerospace engine parts, high-performance sports equipment. |

| Copper (C110) | Excellent electrical and thermal conductivity, corrosion resistance. | Heat sinks, electrical connectors, bus bars, plumbing fittings. |

Benefits of Metal CNC Machining Over Traditional Methods

- Precision & Accuracy: CNC machines can achieve extremely tight tolerances, often within ±0.005 mm (0.0002 inches). This level of precision is critical for parts that must fit together perfectly, such as in aerospace assemblies or medical devices.

- Efficiency & Speed: Automated processes allow for continuous, 24/7 operation with minimal human oversight. This significantly reduces production cycle times compared to manual methods.

- Complexity: Advanced machines, particularly 5-axis CNC mills, can create highly complex geometries, such as contoured surfaces and internal channels, in a single setup. This capability is impossible to replicate with manual techniques.

- Consistency: Because the process is controlled by a computer program, every part produced is virtually identical. This repeatability eliminates the human error inherent in manual machining and ensures high quality across large production runs.

- Cost-Effectiveness: While the initial investment in CNC machinery is high, the long-term costs are often lower due to reduced labor requirements, minimal material waste (as the process is highly optimized), and the ability to scale production up or down with ease.

Applications of Metal CNC Machining Across Industries

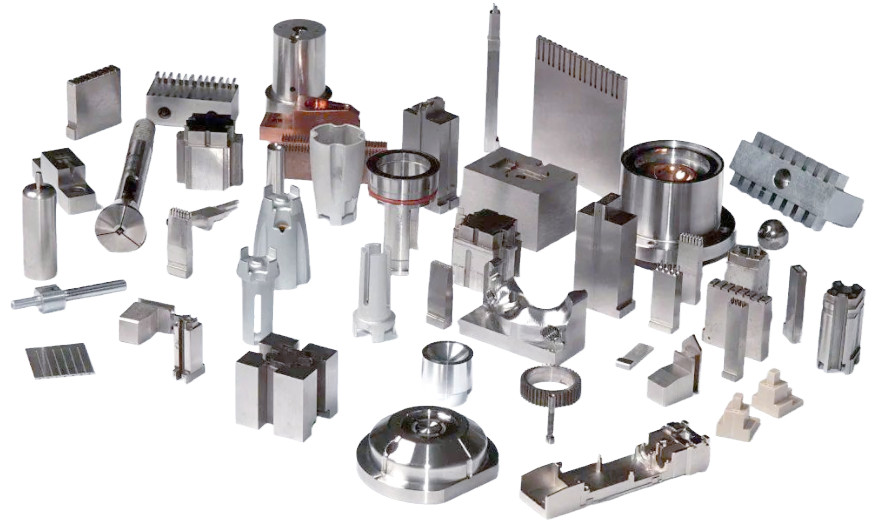

The versatility and precision of metal CNC machining have made it indispensable in numerous sectors.

Aerospace

The aerospace industry relies on CNC machining for flight-critical components that demand absolute reliability and tight tolerances. Examples include turbine blades, engine components, and structural airframe parts made from high-strength aluminum and titanium alloys.

Automotive

In the automotive sector, CNC machining is used for both prototyping new designs and producing end-use parts like custom gears, engine blocks, suspension components, and brackets.

Medical

The medical industry requires parts made from biocompatible materials with flawless surface finishes. CNC machining is used to create surgical tools, orthopedic implants (like hip and knee replacements), and components for diagnostic equipment.

Electronics

CNC machining is used to produce a variety of electronic components, including custom heat sinks from aluminum to dissipate heat, durable enclosures for sensitive devices, and high-conductivity connectors from copper.

How to Choose a Metal CNC Machining Service Provider

Selecting the right partner for your machining needs is crucial for project success. Consider the following criteria:

- Industry Experience: Look for a provider with demonstrated experience in your specific industry. They will be familiar with the relevant standards, materials, and quality requirements.

- Machine Capabilities: Inquire about their equipment. Do they have 3-axis, 4-axis, and 5-axis machines? The more advanced their machinery, the more complex the parts they can produce. Also, confirm their expertise with the specific metal you require.

- Quality Certifications: Certifications are a key indicator of a provider's commitment to quality. Important certifications include ISO 9001 (general quality management), AS9100 (aerospace), and ISO 13485 (medical devices).

- Lead Times and Scalability: Discuss their typical lead times and ensure they can handle the volume of your project, whether it's a single prototype or a high-volume production run.

- Customer Reviews and Portfolio: Review their past work and testimonials to gauge their reliability and the quality of their output.

Conclusion

Metal CNC machining is a powerful and indispensable technology that forms the backbone of modern precision manufacturing. By translating digital designs into physical parts with unparalleled accuracy and efficiency, it drives innovation and enables the creation of complex components across a vast range of industries. Whether you are developing a new product or scaling up production, understanding the fundamentals of CNC machining is essential for leveraging its full potential. For your next project, consider partnering with an experienced CNC machining service to bring your designs to life with precision and quality.

Frequently Asked Questions (FAQs)

What is the typical cost of metal CNC machining?

The cost of a CNC machined part is highly variable and depends on several factors: the type and cost of the raw material, the complexity of the part's geometry, the number of machine setups required, the total machining time, the required tolerances, and the production volume (higher quantities typically have a lower per-unit cost).

How long does a CNC machining project take?

Lead times can range from a few days for simple prototypes to several weeks or months for complex, high-volume production runs. The timeline is influenced by design complexity, material availability, machine scheduling, and any required post-processing or finishing steps.

What’s the difference between CNC milling and turning?

The primary difference lies in which component moves. In CNC milling, the cutting tool rotates and moves along multiple axes to remove material from a stationary workpiece. It is used to create flat surfaces, slots, and complex 3D shapes. In CNC turning (done on a lathe), the workpiece rotates at high speed while a stationary cutting tool removes material. It is used to create cylindrical, conical, and threaded parts.

Can CNC machines work with exotic metals?

Yes, specialized CNC machines equipped with high-torque spindles, rigid frames, and advanced cooling systems can effectively machine exotic and superalloys like Inconel, Monel, Hastelloy, and various grades of titanium. These materials are difficult to machine due to their high strength and poor thermal conductivity, requiring specific expertise and equipment.

How do I prepare a CAD file for CNC machining?

To prepare a CAD file, ensure it is in a standard, universal format like STEP (.stp) or IGES (.igs). The model should be a solid body with all features clearly defined. It is also crucial to include a 2D drawing that specifies all dimensions, critical tolerances, material type, required surface finish, and any other manufacturing notes.