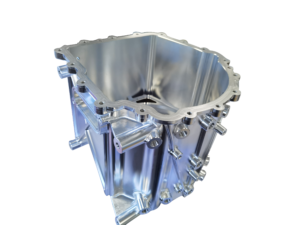

Motor housings are integral components of electric motor systems, providing protection, structural support, and thermal management for critical internal components like stators, rotors, and bearings. Their design and manufacturing directly influence motor performance, reliability, and longevity across diverse applications, from industrial automation to electric vehicles. This article explores the key characteristics of motor housings, such as robust protection and excellent heat dissipation, and their defining features, including material diversity and processing adaptability. It also details their applications in various industries, offering technical parameters and insights to support engineers, designers, and manufacturers in understanding their functionality and implementation.

Key Characteristics of Motor Housings

Motor housings are engineered to meet stringent performance requirements, balancing mechanical strength, thermal efficiency, and precision. These characteristics ensure reliable operation under diverse conditions, from high-vibration industrial environments to compact consumer appliances.

Robust Protection

Motor housings shield internal components from environmental hazards such as dust, moisture, corrosive substances, and mechanical impacts. This protection is critical for ensuring consistent motor operation and extending service life.

Technical Parameters: Housings designed to IP65 standards withstand water jets at 12.5 L/min and dust ingress, using seals with a Shore A hardness of 70–80. Aluminum alloy (6061-T6) housings achieve impact resistance up to 7 J, suitable for industrial settings.

Protective features include sealed bearing covers and gaskets, with wall thicknesses of 3–8 mm to resist deformation under loads up to 500 MPa.

Excellent Heat Dissipation

Efficient heat dissipation prevents overheating, which can degrade insulation or damage bearings. Housings incorporate materials with high thermal conductivity and structural features like fins or ribs to enhance cooling.

Technical Parameters: Aluminum alloy (A356) housings with thermal conductivity of 150–170 W/m·K maintain motor temperatures below 80°C. Cooling fins, spaced 5–10 mm apart and 10–20 mm tall, increase surface area by 30–50%, improving convective heat transfer.

Computational fluid dynamics (CFD) simulations are often used to optimize fin geometry, ensuring airflow rates of 1–2 m/s for effective cooling.

High Structural Strength

Motor housings must withstand vibrations, dynamic loads, and installation stresses without compromising alignment or integrity. High mechanical strength and rigidity are essential for reliable operation.

Technical Parameters: Cast iron (ASTM A48) housings offer compressive strengths of 800–1000 MPa, supporting motors with power outputs up to 500 kW. Aluminum housings (ADC12) with tensile strengths of 200–300 MPa are used for motors up to 100 kW.

Finite element analysis (FEA) ensures housings resist vibrational frequencies of 10–100 Hz, with deflection limited to 0.01 mm under 1000 N loads.

High Dimensional Accuracy

Precise dimensions and tight tolerances ensure proper alignment of rotating components, minimizing energy losses and wear. Coaxiality and geometric tolerances are critical for smooth operation.

Technical Parameters: CNC-machined housings achieve bearing seat tolerances of ±0.01 mm and coaxiality of ±0.005 mm. Surface finishes of Ra 0.8–1.6 µm reduce friction in bearing assemblies.

Coordinate Measuring Machines (CMMs) verify critical dimensions, with roundness tolerances of ±0.01 mm for bearing bores.

Adaptable Installation Options

Motor housings are designed to support various mounting configurations, such as flange, foot, vertical, or horizontal setups, facilitating integration into diverse systems.

Technical Parameters: Flange-mounted housings (ISO 3019 standard) feature bolt patterns with positional tolerances of ±0.02 mm. Foot-mounted housings use base plates with flatness tolerances of ±0.05 mm, supporting loads up to 2000 N.

Modular designs allow interchangeability, with mounting features machined using CNC milling at 200–300 m/min for aluminum or 80–120 m/min for cast iron.

Defining Features of Motor Housings

Motor housings are characterized by their versatility and adaptability, enabling customization to meet specific operational and aesthetic requirements. These features enhance their functionality across a wide range of applications.

Material Diversity

Motor housings are manufactured from a variety of materials, each selected based on mechanical, thermal, and environmental needs:

- Aluminum Alloys (e.g., A356, 6061-T6): Lightweight (2.7 g/cm³), with thermal conductivity of 150–170 W/m·K, used in electric vehicles and automation.

- Cast Iron (e.g., ASTM A48): High compressive strength (800–1000 MPa) and vibration damping, ideal for industrial motors.

- Stainless Steel (e.g., 304, 316): Corrosion-resistant, with tensile strengths of 500–700 MPa, suited for harsh environments.

- Engineering Plastics (e.g., PEEK, Nylon): Lightweight (1.2–1.8 g/cm³) and insulating, used in low-load consumer electronics.

Material selection balances cost ($1–2/kg for cast iron vs. $5–10/kg for stainless steel) and performance, with machining parameters adjusted accordingly (e.g., 50–80 m/min for stainless steel).

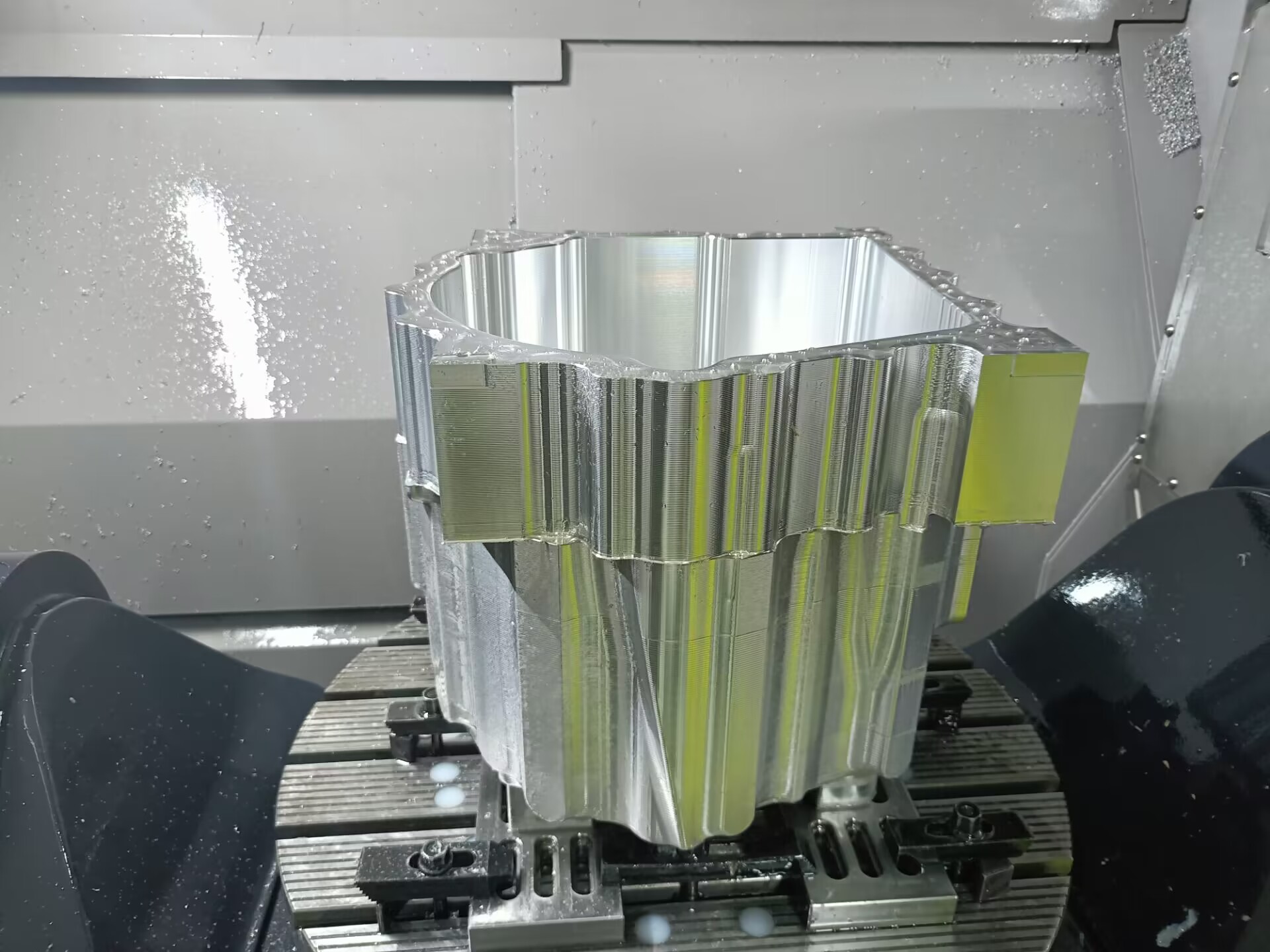

Processing Adaptability

Motor housings are compatible with multiple manufacturing processes, including CNC machining, die casting, sand casting, and sheet metal fabrication, allowing flexibility in production scale and complexity.

Technical Parameters: Die-cast aluminum housings achieve tolerances of ±0.1 mm with cycle times of 30–60 seconds. CNC machining offers ±0.01 mm tolerances, using 5-axis mills at feed rates of 0.1–0.2 mm/tooth.

Process selection depends on production volume, with die casting preferred for 10,000+ units and CNC machining for prototyping or small batches.

Flexible Aesthetic Customization

Surface treatments enhance both corrosion resistance and visual appeal, meeting aesthetic and functional requirements.

Technical Parameters: Anodized aluminum housings achieve a coating thickness of 10–20 µm, with corrosion resistance up to 500 hours in salt spray tests. Powder coating on cast iron provides a 50–100 µm layer, with adhesion strength of 5–7 MPa.

Treatments like electrophoresis or polishing (Ra 0.8 µm) are applied for consumer-facing applications, ensuring durability and market appeal.

Support for Sealing and Protection Ratings

Motor housings can be designed to meet various ingress protection (IP) ratings, such as IP54, IP65, or IP67, ensuring suitability for diverse environments.

Technical Parameters: IP67-rated housings use silicone gaskets with a compression set of 20–30% and O-rings with a Shore A hardness of 70. Sealing surfaces are machined to Ra 0.8 µm, with flatness tolerances of ±0.02 mm.

Designs incorporate labyrinth seals or double-lip seals to prevent water and dust ingress, validated through pressure testing at 0.5–1 bar.

Applications of Motor Housings Across Industries

Motor housings are used in a wide range of industries, each with unique requirements for material, design, and performance. The following sections detail their applications, with technical insights into implementation.

Industrial Automation Equipment

Motor housings in industrial automation support precise motion control in high-performance systems.

Applications:

- Servo Motors: Aluminum housings (6061-T6) with ±0.01 mm bearing seat tolerances ensure positional accuracy of ±0.005°.

- Stepper Motors: Die-cast ADC12 housings with cooling fins maintain temperatures below 70°C for continuous operation.

- Geared Motors: Cast iron housings (ASTM A536) dampen vibrations to 1–2 mm/s in conveyor systems.

Technical Parameters: Housings are CNC-machined at 200–300 m/min, with IP65 seals for dust and water resistance. Flange mounts adhere to IEC 60034 standards, with bolt holes machined to ±0.02 mm.

New Energy Vehicles

In electric vehicles, motor housings prioritize lightweight construction and efficient heat dissipation to enhance range and performance.

Applications: Drive motor housings use die-cast aluminum (AlSi10Mg) with weights of 2–5 kg and thermal conductivity of 150 W/m·K.

Technical Parameters: Housings feature integrated cooling channels, machined to ±0.05 mm, supporting coolant flow rates of 5–10 L/min. Surface anodizing (15 µm) ensures corrosion resistance for 1000 hours in salt spray tests.

Household Appliances and Power Tools

Motor housings in consumer products balance functionality with aesthetic and cost considerations.

Applications:

- Washing Machines: PEEK housings with insulation resistance of 10^8 Ω reduce weight to 0.5–1 kg.

- Vacuum Cleaners: Aluminum housings with powder coating (50 µm) enhance durability and appearance.

- Power Tools: Die-cast ADC12 housings with IP54 protection withstand dust and light moisture.

Technical Parameters: Housings are machined to Ra 1.6 µm, with mounting features toleranced to ±0.05 mm. Production uses high-speed die casting with cycle times of 30–60 seconds.

Wind and Hydropower Equipment

Motor housings in renewable energy systems must endure harsh environmental conditions, such as high humidity and corrosion.

Applications: Stainless steel (316) housings with IP67 protection are used in wind turbine generators and hydropower pumps.

Technical Parameters: Housings are CNC-machined at 50–80 m/min, with sealing surfaces polished to Ra 0.8 µm. Corrosion resistance is validated for 2000 hours in salt spray tests, with wall thicknesses of 5–10 mm.

Pumps and Compressors

Motor housings in pumps and compressors are often integrated with system components like brackets or flanges.

Applications: Cast iron housings (ASTM A48) with sand casting + CNC machining support motors with power outputs of 50–200 kW.

Technical Parameters: Bearing seats are bored to ±0.015 mm, with mounting flanges milled to ±0.02 mm flatness. Vibration damping reduces noise to 60–70 dB under 1000 RPM operation.

Conclusion

Motor housings are critical components that ensure the reliability, efficiency, and longevity of electric motor systems. Their characteristics—robust protection, excellent heat dissipation, high structural strength, dimensional accuracy, and adaptable installation—enable them to meet diverse operational demands. Features like material diversity, processing adaptability, aesthetic customization, and support for high IP ratings enhance their versatility across industries such as industrial automation, electric vehicles, and renewable energy. By understanding these characteristics and applications, engineers and manufacturers can select and design motor housings that optimize performance and integration, supporting innovation in motor-driven technologies.

Frequently Asked Questions (FAQ)

What are the primary functions of motor housings?

Motor housings protect internal components from dust, moisture, and impacts, dissipate heat to prevent overheating, provide structural strength to withstand loads, and ensure precise alignment for efficient operation.

Which materials are most commonly used for motor housings?

Aluminum alloys (e.g., A356, 6061-T6) are used for lightweight and thermal conductivity, cast iron (e.g., ASTM A48) for cost and strength, stainless steel (e.g., 316) for corrosion resistance, and plastics (e.g., PEEK) for insulation in low-load applications.

How do motor housings achieve high IP ratings like IP65 or IP67?

High IP ratings are achieved using silicone gaskets (Shore A 70), O-rings, and precisely machined sealing surfaces (Ra 0.8 µm, flatness ±0.02 mm). Designs incorporate labyrinth seals and are tested at 0.5–1 bar to ensure water and dust resistance.

What industries rely on motor housings?

Key industries include industrial automation (servo motors, robotics), new energy vehicles (electric drivetrains), household appliances (washing machines, power tools), wind/hydropower (generators), and pumps/compressors (industrial systems).