Motor housings play a critical role in electric motor systems, providing structural support, protecting internal components, and facilitating heat dissipation. Their design and manufacturing directly impact motor performance, durability, and cost. This article explores the materials commonly used for motor housings, such as aluminum alloys, cast iron, and stainless steel, and examines prototyping methods like CNC machining and 3D printing. It also compares mainstream machining processes, including die casting and sheet metal fabrication, offering detailed technical parameters and practical guidance for selecting materials and processes based on application needs.

Introduction to Motor Housings

Motor housings serve as the outer enclosure for electric motors, ensuring alignment of rotating components, protecting against environmental factors, and dissipating heat generated during operation. Their performance requirements include high structural strength, excellent thermal conductivity, precise dimensional accuracy, and optimized weight. These demands vary depending on the application, such as lightweight housings for electric vehicles or robust enclosures for heavy industrial motors.

Material selection influences properties like corrosion resistance and machinability, while manufacturing processes affect production scalability and cost. Balancing these factors is essential to meet performance goals while maintaining economic viability. The following sections detail the materials, prototyping methods, and machining processes used in motor housing production, with insights into their applications and trade-offs.

Common Materials for Motor Housings and Their Characteristics

The choice of material for motor housings is driven by mechanical, thermal, and environmental requirements. Aluminum alloys, cast iron, stainless steel, and engineering plastics are the primary options, each offering distinct advantages and limitations.

Aluminum Alloys

Aluminum alloys are widely used due to their lightweight nature, high thermal conductivity, and corrosion resistance. Common grades include A356, 6061-T6, and ADC12, with tensile strengths of 200–300 MPa and thermal conductivity of 150–170 W/m·K.

Advantages:

- Lightweight, with a density of 2.7 g/cm³, reducing motor weight by 30–50% compared to cast iron.

- High thermal conductivity ensures efficient heat dissipation, maintaining motor temperatures below 80°C.

- Corrosion resistance, enhanced by anodizing, suits outdoor or humid environments.

- Excellent machinability, supporting CNC milling at cutting speeds of 200–300 m/min.

Applications: Electric vehicle motors, automation equipment, and high-speed fans, where weight and heat dissipation are critical.

Considerations: Aluminum is more expensive than cast iron, with costs ranging from $3–5/kg, and requires precise machining to achieve tight tolerances (±0.02 mm).

Cast Iron

Cast iron, such as gray cast iron (ASTM A48) or ductile iron (ASTM A536), is valued for its cost-effectiveness and structural rigidity. It has a tensile strength of 200–400 MPa and a density of 7.2 g/cm³.

Advantages:

- Low cost, typically $1–2/kg, making it ideal for budget-sensitive applications.

- Excellent vibration damping, reducing noise levels to 60–70 dB in heavy machinery.

- High compressive strength, supporting loads up to 1000 MPa in industrial motors.

Applications: Heavy-duty industrial motors, centrifugal pumps, and compressors, where robustness is prioritized.

Considerations: Its high density increases motor weight, and machining requires lower cutting speeds (80–120 m/min) due to abrasiveness. Surface finishes are typically Ra 1.6–3.2 µm.

Stainless Steel

Stainless steel, such as 304 or 316, offers superior corrosion resistance and strength, with tensile strengths of 500–700 MPa and a density of 8.0 g/cm³.

Advantages:

- Exceptional corrosion resistance, ideal for harsh environments like marine or chemical plants.

- High strength supports compact designs with wall thicknesses as low as 3–5 mm.

- Polishable to Ra 0.8 µm for hygienic applications.

Applications: Food processing equipment, motors in wet or corrosive environments, and precision instruments.

Considerations: Higher cost ($5–10/kg) and lower thermal conductivity (15–20 W/m·K) limit its use in high-heat applications. Machining requires carbide tools at 50–80 m/min to prevent work hardening.

Engineering Plastics and Composites

Engineering plastics like PEEK or nylon, and composites like carbon-fiber-reinforced polymers, are used in niche applications requiring insulation or lightweight properties. They have tensile strengths of 80–150 MPa and densities of 1.2–1.8 g/cm³.

Advantages:

- Electrical insulation, critical for motors with high electromagnetic interference.

- Lightweight, reducing motor weight by up to 70% compared to metals.

- Corrosion-free, suitable for chemical exposure.

Applications: Small, low-load motors in medical devices or consumer electronics.

Considerations: Limited strength and thermal conductivity (0.2–0.5 W/m·K) restrict use to low-power applications. Machining is performed at 100–150 m/min with minimal heat generation.

Prototyping Methods for Motor Housings

Prototyping is a crucial step in motor housing development, allowing designers to validate functionality, fit, and performance before full-scale production. Common methods include CNC machining, 3D printing, and silicone molding, each suited to different stages of development.

Rapid CNC Machining

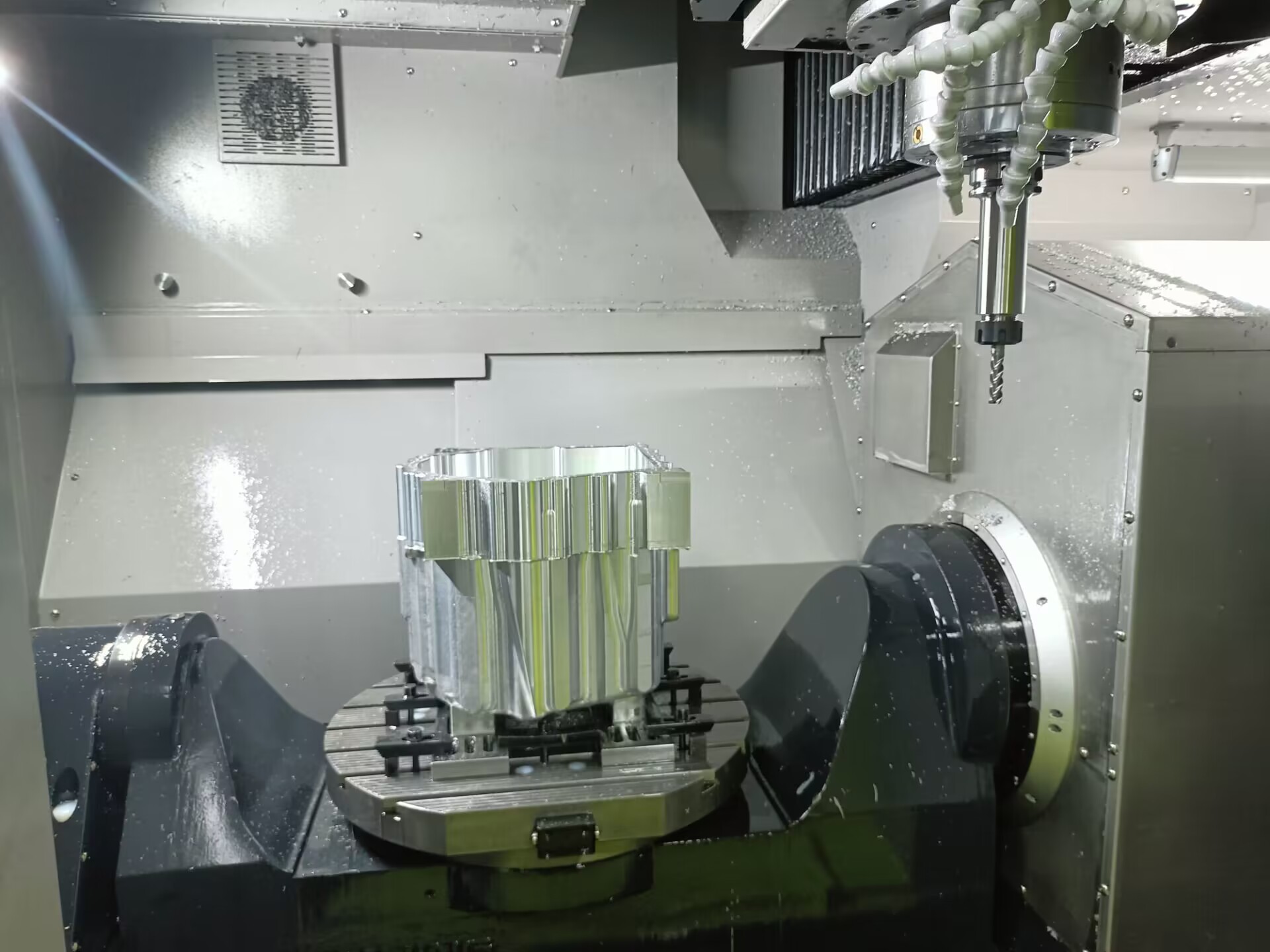

CNC machining is ideal for producing high-precision prototypes in metals like aluminum or stainless steel, enabling direct functional testing.

Process: A 5-axis CNC mill machines the housing from a solid block, achieving tolerances of ±0.01 mm and surface finishes of Ra 0.8–1.6 µm. For an aluminum A356 housing, milling is performed at 200–300 m/min with a feed rate of 0.1–0.2 mm/tooth.

Advantages:

- High accuracy, suitable for fit and thermal testing.

- Material versatility, supporting aluminum, stainless steel, or cast iron.

- Prototypes are near-production quality, reducing design iterations.

Limitations: High cost ($500–2000 per prototype) and longer lead times (1–2 weeks) for complex geometries.

Applications: Small-batch prototyping for automotive or industrial motors.

3D Printing (Metal and Polymer)

3D printing, particularly metal additive manufacturing (e.g., selective laser melting), is used for complex housing designs and early-stage validation.

Process: Metal 3D printers build housings layer by layer using aluminum (AlSi10Mg) or stainless steel (316L) powders, achieving tolerances of ±0.1 mm. Build rates are 20–50 cm³/h, with post-processing (e.g., CNC finishing) to achieve Ra 1.6 µm.

Advantages:

- High design freedom, enabling intricate cooling channels or lightweight lattice structures.

- Rapid iteration, with prototypes completed in 3–7 days.

- Polymer 3D printing (e.g., SLA for PEEK) supports non-metal prototypes.

Limitations: High cost ($1000–5000 per part) and lower strength in as-printed parts, requiring heat treatment.

Applications: Complex design validation for aerospace or high-performance motors.

Silicone Molding and Casting

Silicone molding is used for prototyping plastic or composite housings, offering a cost-effective alternative for non-metal designs.

Process: A master model (often 3D-printed) is used to create a silicone mold, into which polyurethane or epoxy is poured. Prototypes achieve tolerances of ±0.2 mm and surface finishes of Ra 1.6–3.2 µm.

Advantages:

- Low cost ($50–200 per prototype) and fast lead times (2–5 days).

- Suitable for small batches (10–50 units).

- Supports complex geometries with minimal tooling.

Limitations: Limited to non-metal materials and lower strength, unsuitable for functional testing under high loads.

Applications: Prototyping lightweight housings for consumer electronics or medical devices.

Comparison of Mainstream Machining Processes

Motor housing production involves various machining processes, each with unique advantages, limitations, and applications. The table below compares five mainstream processes, followed by detailed explanations.

| Process | Advantages | Disadvantages | Applications |

|---|---|---|---|

| CNC Machining | High precision (±0.01 mm), material flexibility | High cost, longer lead times | Prototyping, small-batch production |

| Die Casting (Aluminum) | Low per-unit cost, high output | High mold cost ($10,000–50,000), design restrictions | Mass production of standard parts |

| Metal 3D Printing | Complex geometries, rapid iteration | High cost, low efficiency | Complex design validation, customization |

| Casting + Machining | Moderate cost, suitable for large parts | Requires secondary machining for precision | Medium-to-large structural components |

| Sheet Metal Fabrication | Low cost, short lead times | Limited strength and complexity | Light-duty, non-critical applications |

CNC Machining

CNC machining uses multi-axis mills or lathes to produce housings with tolerances of ±0.01 mm and surface finishes of Ra 0.8 µm. For a 6061-T6 aluminum housing, milling parameters include a cutting speed of 200–300 m/min, feed rate of 0.1–0.2 mm/tooth, and depth of cut of 0.5–2 mm.

Applications: Prototyping and small-batch production for high-precision motors in automation or aerospace.

Considerations: Cost ($50–100/hour) and lead time (1–3 weeks) increase with complexity.

Die Casting (Aluminum)

Die casting produces aluminum housings in high volumes, with cycle times of 30–60 seconds per part. ADC12 alloy is commonly used, achieving tolerances of ±0.1 mm.

Applications: Mass production of electric vehicle or fan motor housings.

Considerations: High initial mold costs require production runs of 10,000+ units to be cost-effective. Post-machining may be needed for bearing seats (±0.02 mm).

Metal 3D Printing

Metal 3D printing builds housings using AlSi10Mg or 316L, with layer thicknesses of 20–50 µm and build rates of 20–50 cm³/h. Post-processing includes heat treatment and CNC finishing to achieve Ra 1.6 µm.

Applications: Custom or complex housings for aerospace or high-performance motors.

Considerations: Costs ($100–500/kg of material) and build times (1–2 weeks) limit scalability.

Casting + Machining

Sand or investment casting produces cast iron or aluminum housings, followed by CNC machining for precision features. Tolerances improve from ±0.5 mm (as-cast) to ±0.02 mm after machining.

Applications: Medium-to-large housings for industrial pumps or compressors.

Considerations: Moderate cost ($2–5/kg) but requires multiple processing steps.

Sheet Metal Fabrication

Sheet metal fabrication involves cutting, bending, and welding steel or aluminum sheets (1–3 mm thick) to form housings, with tolerances of ±0.2 mm.

Applications: Lightweight, non-critical housings for consumer electronics or ventilation systems.

Considerations: Limited structural strength restricts use to low-load applications.

Process and Material Selection Guidelines

Selecting the optimal material and process for motor housings depends on production volume, application requirements, and cost constraints. Below are guidelines for different scenarios.

By Production Stage

- Prototyping (1–10 units): CNC machining or 3D printing for metal housings; silicone molding for plastics. CNC machining achieves ±0.01 mm tolerances, while 3D printing supports complex designs.

- Small-Batch Production (10–1000 units): CNC machining or casting + machining. Aluminum or cast iron housings are machined to Ra 0.8–1.6 µm for precision fit.

- Mass Production (1000+ units): Die casting for aluminum or casting + machining for cast iron. Die casting reduces per-unit costs to $1–5 for large runs.

By Industry/Application

- Automotive (Electric Vehicles): Aluminum die-cast housings (ADC12) for lightweight (2–5 kg) and thermal efficiency (150 W/m·K).

- Heavy Industry (Pumps, Compressors): Cast iron housings (ASTM A48) with sand casting + CNC machining for durability under 500–1000 MPa loads.

- Food Processing: Stainless steel (316) CNC-machined housings, polished to Ra 0.8 µm for hygiene.

- Consumer Electronics: PEEK or nylon housings via silicone molding or 3D printing for insulation and weight reduction.

Balancing Cost, Precision, and Lead Time

Cost, precision, and lead time must be balanced based on project priorities:

- High Precision: CNC machining or post-processed 3D printing, with tolerances of ±0.01–0.02 mm, at $50–100/hour.

- Low Cost: Die casting or sheet metal fabrication, with per-unit costs of $1–5 for large volumes.

- Short Lead Time: Sheet metal fabrication or silicone molding, with prototypes completed in 2–5 days.

Finite element analysis (FEA) and thermal simulations can guide material and process selection, optimizing for stress distribution and heat dissipation.

Conclusion

Motor housing manufacturing requires careful consideration of materials, prototyping methods, and machining processes to achieve optimal performance and cost-efficiency. Aluminum alloys, cast iron, stainless steel, and plastics each serve specific applications, from lightweight electric vehicle motors to robust industrial pumps. Prototyping methods like CNC machining and 3D printing enable rapid design validation, while processes like die casting and casting + machining support scalable production. By aligning material and process choices with production stage, industry needs, and performance requirements, manufacturers can produce high-quality motor housings. Future trends, such as lightweight designs, integrated functionality, and sustainable materials, will further shape motor housing development, driving innovation in electric motor systems.

Frequently Asked Questions (FAQ)

What materials are commonly used for motor housings?

Common materials include aluminum alloys (e.g., A356, 6061-T6), cast iron (e.g., ASTM A48), stainless steel (e.g., 304, 316), and engineering plastics (e.g., PEEK). Aluminum is favored for lightweight and thermal conductivity, while cast iron is cost-effective and robust.

Which prototyping method is best for motor housings?

CNC machining is ideal for high-precision metal prototypes (±0.01 mm), 3D printing suits complex designs, and silicone molding is cost-effective for plastic prototypes. The choice depends on material, complexity, and testing requirements.

How does die casting compare to CNC machining for motor housings?

Die casting offers low per-unit costs ($1–5) and high output for mass production but requires expensive molds ($10,000–50,000). CNC machining provides higher precision (±0.01 mm) but is costlier ($50–100/hour) and suited for prototyping or small batches.

What factors influence motor housing process selection?

Key factors include production volume (prototyping vs. mass production), application requirements (e.g., weight, strength, corrosion resistance), cost constraints, and lead time. Precision needs and material properties also guide the choice.