Ball nose end mills have long been the preferred tool for machining smooth surfaces in mold finishing. However, their limitations are increasingly evident, particularly when finishing large surface areas. The stepover for ball nose end mills is typically constrained to 3-5% of the tool diameter, resulting in limited material contact. This requires a higher number of passes to achieve the desired surface finish, increasing stress and wear on the cutting tool. Additionally, the reduced stepover length, necessitated by more passes, extends manufacturing cycle times significantly.

In contrast, circle segment end mills—a newer design featuring a larger cutting radius—offer a solution by enabling wider stepovers and cutting broader sections of material in fewer passes. This advancement reduces tool paths, extends tool life, boosts efficiency, and shortens production cycles. Below, the process of optimizing mold finishing is explored, comparing traditional methods with circle segment technology, supported by practical applications and technical insights.

Challenges of Ball Nose End Mills in Mold Finishing

Ball nose end mills, despite their utility in certain contexts, pose several challenges when applied to mold finishing, especially for complex geometries or large surfaces:

- Small Stepover: Limited to 3-5% of the tool diameter, requiring numerous passes to cover the surface.

- Tool Wear: Increased passes elevate stress, accelerating wear and necessitating frequent tool replacement.

- Prolonged Cycle Times: The multiplicity of passes directly correlates with longer machining durations.

For instance, in machining freeform surfaces or hard-to-reach areas—such as those found in automotive molds—these limitations become pronounced. The small contact area of the ball nose end mill demands meticulous, time-consuming operations to achieve acceptable surface quality.

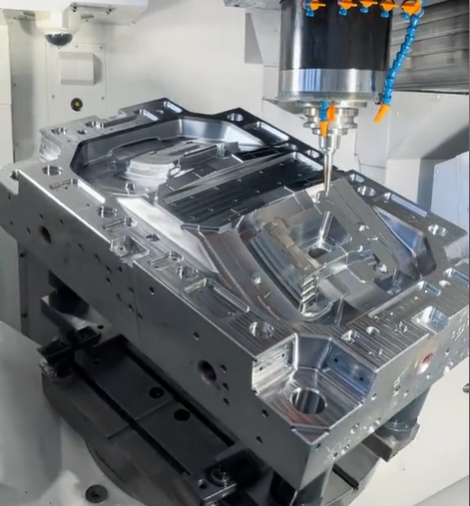

Circle Segment End Mills: A Revolutionary Approach

Circle segment end mills address these inefficiencies through a design that incorporates a partial arc on the cutting edge, resulting in a significantly larger cutting radius. This allows the tool to simulate a cutting diameter ranging from 12mm to over 3000mm, far exceeding that of traditional ball nose end mills.

Key Features of Circle Segment End Mills

- Large Cutting Radius: Enables wider stepovers, reducing the number of required passes.

- Enhanced Material Removal: Cuts broader sections in a single pass, improving throughput.

- Optimized Tool Life: Distributes cutting forces more evenly, minimizing wear.

The large radial stepover is a defining characteristic, generating greater cutting forces due to the expanded radius. This design not only enhances efficiency but also maintains precision across complex surfaces.

Advantages in Mold Finishing

The adoption of circle segment end mills yields measurable benefits:

- Reduced Thermal Deformation: Limits tolerance deviations caused by heat buildup.

- Consistent Axial Performance: Smooths deviations, ensuring uniform quality.

- Efficiency in Five-Axis Machining: Removes more material with fewer passes, reducing cycle times by over 80% and improving surface finish by 50%.

These advantages make circle segment end mills particularly suited for intricate molds machining requiring high precision and minimal post-processing.

Practical Applications of Circle Segment Technology

Real-world examples illustrate how circle segment end mills transform mold finishing processes, offering substantial improvements over traditional methods.

Case Study: Automotive Plastic Injection Molding

An automotive plastic injection molder enhanced productivity by integrating circle segment end mills into five-axis machining of complex molds making. These molds prototypes, often up to 10 feet long and 5 feet wide, include components such as bumpers, cup holders, gear shifts, dashboards, and engine compartments.

Material and Mold Specifications

- Material: P-20 tool steel, hardness 32/34 HRC.

- Mold Features: High tapers, arcs, contours, and angles across both mold halves.

- Challenges: Deep lifter pockets with restricted access, critical for ejecting plastic parts.

Comparison of Approaches

Previously, the molder relied on ball nose end mills, which, with their 6mm radius (for a 12mm diameter tool), required multiple passes due to a small contact area. Switching to circle segment end mills, with a 250mm cutting radius for the same 12mm diameter, dramatically increased the effective cutting area. To ensure rigidity, shrink-fit tool holders were employed, providing ample clearance for machining larger molds making.

Outcomes

- Cycle Time Reduction: Finishing time decreased by approximately 80%.

- Tool Life Improvement: Doubled compared to ball nose end mills.

- Cost Efficiency: Machining costs dropped by 70%, saving over $50,000 annually.

This case highlights the versatility of circle segment end mills in machining specific mold machining features alongside other tools, slashing cutting times significantly.

Large Fascia Mold Application

In machining a large fascia mold making, tangential plane machining with circle segment end mills proved effective, particularly for deep slots challenging to side mill with standard tools.

Traditional vs. Circle Segment Methods

Conventionally, ball nose end mills with small stepovers were used, leaving excess material in corners that required additional removal steps. Circle segment end mills, however, cut efficiently into vertical corners and slot bottoms. The process mirrors traditional milling, with unique features ground onto standard shanks (e.g., 16mm or 12mm).

Cutting Parameters

Parameters depend on effective diameter, cutting edge count, and workpiece material. Initial settings use recommended speeds and feeds, adjusted per conditions. Due to increased cutting forces from the large radius and greater contact, feed rates may decrease slightly. Yet, the wider stepover enhances overall efficiency.

| Tool Type | Diameter (mm) | Cutting Radius (mm) | Stepover (% of Diameter) | Cycle Time (Example) |

|---|---|---|---|---|

| Ball Nose End Mill | 12 | 6 | 3-5% | 9h 36m |

| Circle Segment End Mill | 12 | 250 | Variable (Wider) | 1h 10m |

Results

For this mold prototyping, ball nose end mill machining took 9 hours and 36 minutes, while circle segment end mills reduced it to 1 hour and 10 minutes—an 88% reduction. Surface quality improved, minimizing post-polishing needs.

Software Requirements for Circle Segment Technology

Effective use of circle segment end mills hinges on CAM software capable of generating precise tool paths. This is critical due to the tool’s constantly changing contact angle.

Essential CAM Features

- Automatic Contact Point Control: Ensures safe, uniform cutting across surfaces.

- Parametric Tool Definition: Simplifies tool setup without manual geometry creation.

- Tool Management: Maps tools accurately for reliable operation.

Manufacturers must verify CAM compatibility, potentially upgrading to software supporting circle segment paths to maximize benefits.

Extending Reading Content

Mold manufacturers can learn from the following three five-axis finishing applications using circle segment technology:

Removing Large Amounts of Material in Tapered Surface Applications

This project started with a 100-pound block of 6061-T6 aluminum, reduced to just 6 pounds after milling machining. The manufacturer had circle segment end mills but needed programming assistance. Collaborating with the cutting tool supplier, they established tool paths and parallel functions with surface tilt options.

Previously, finishing the surface with a ball nose end mill took nearly 5 hours per part. With circle segment end mills, they completed the task in just 38 minutes, saving significant time. The CAM software’s ability to handle the large radius on the circle segment end mill was crucial for maintaining geometric accuracy.

Five-Axis Machining of 6061-T6 Aluminum Aerospace Parts

Initially, this project took 30 minutes to complete, making it unprofitable. With guidance from the tool supplier, engineers modified the tool paths to use a 12mm lens-shaped circle segment end mill quickly. By maintaining the same feed and speed as the previous tool, they reduced the cycle time to 3.5 minutes, an 89% improvement. This not only saved $66,000 on the first order of 1000 pieces but also enhanced the surface finish of aluminum parts.

Finishing an Aluminum Turbo Intake Header

The header had steep sides and constantly changing contours. Initially, a two-flute 0.500-inch ball nose end mill was used at 800 SFM with a 0.010-inch stepover, taking over ten hours to complete. The end mill lasted for 15 parts before needing replacement.

Switching to a circle segment end mill with an FPC milling chuck, they used a 12mm circle segment end mill with three flutes and a 250mm radius. Increasing the cutting speed to 1900 SFM and the stepover to 0.060 inches, they completed the job in just 27 minutes. One circle segment end mill machined 30 parts, compared to 15 with the traditional ball nose end mill. Both tools achieved an average surface finish of Ra=63, but the circle segment end mill saved hours per job, resulting in $1000 savings per part. Despite the higher cost of circle segment end mills, the cost savings per job exceeded 95%.

KeSu Rapid Tooling Service

KeSu offers precision tooling and custom mold design tailored to diverse industrial needs. With design for manufacturability (DFM) feedback to help optimize your mold design for production, and a focus on quality assurance, we ensure efficient and reliable production solutions for every project.

- Custom mold design for specific needs

- Tools are machined to DIN-27681-fine standards

- Advanced In-house Equipments

Conclusion

Optimizing mold finishing machining with circle segment end mills delivers remarkable improvements in cycle time, tool longevity, and surface quality. By integrating this technology with compatible CAM software, manufacturers can achieve substantial efficiency gains and cost reductions, revolutionizing mold production processes.

FAQs

What are circle segment end mills?

Circle segment end mills feature a unique arc-shaped cutting edge with a large radius, enabling wider stepovers and fewer passes compared to traditional tools.

How do they enhance mold finishing?

They reduce cycle times by over 80%, extend tool life, and improve surface finish by 50% through larger stepovers and efficient material removal.

What CAM software is needed?

CAM software must support precise tool path generation, automatic contact point control, and parametric tool definition for effective use.

Are they suitable for all molds?

Their effectiveness varies with mold geometry and software capabilities, excelling in complex, hard-to-reach areas.

What are the cost benefits?

Despite higher initial costs, savings from reduced machining time and tool longevity often exceed 70%, as seen in practical applications.