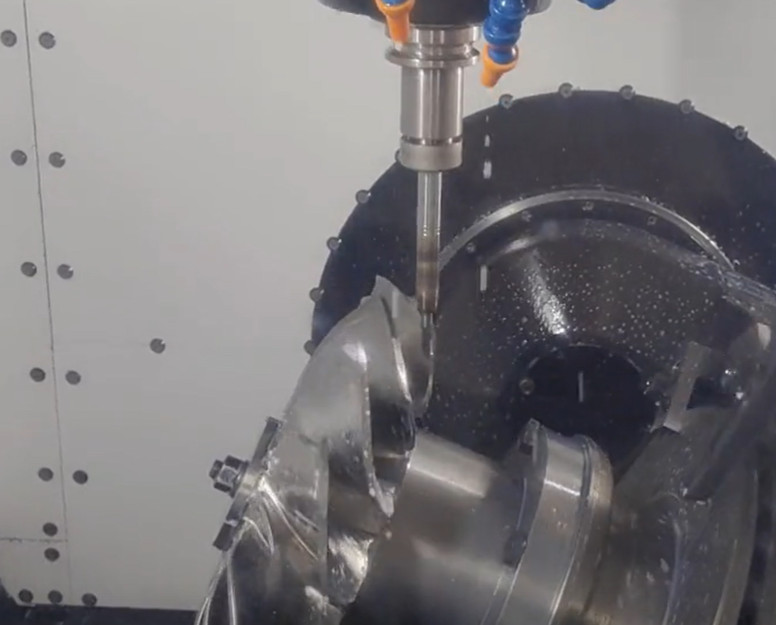

Impellers, critical components in turbomachinery, feature complex, free-form surfaces that demand high precision and surface quality. Swiss Mikron five-axis CNC machines, known for their dynamic performance and accuracy, are well-suited for machining these intricate geometries. This guide provides a detailed, technical approach to optimizing impeller machining, focusing on toolpath strategies, machine setup, parameter selection, and process integration. The content is structured to deliver practical insights for manufacturers aiming to achieve superior results.

Understanding Impeller Geometry and Machining Requirements

Impellers, particularly centrifugal impellers, consist of three-dimensional elements such as hubs, blades with significant twists, and leading and trailing edges. These free-form, thin-walled structures require tight tolerances (typically 1–5 μm) and surface finishes (Ra 0.04–0.06 μm) to ensure aerodynamic efficiency and energy conversion. Five-axis machining is essential to access complex surfaces in a single setup, reducing errors from multiple clampings.

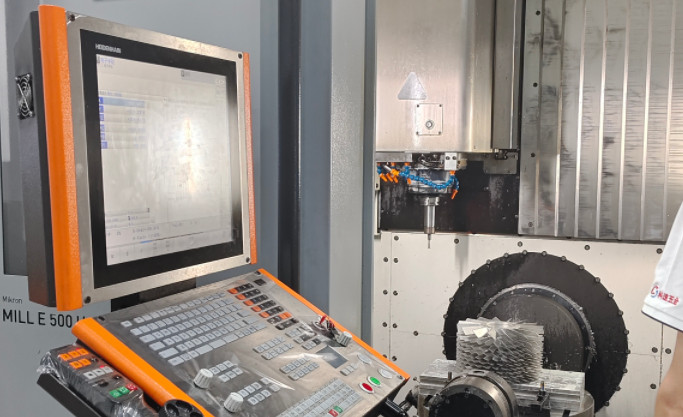

Mikron’s five-axis machines, such as the MILL S/X U and MILL P U series, offer simultaneous control of linear (X, Y, Z) and rotational (A, C) axes, enabling precise tool orientation. Key requirements include minimizing toolpath deviations, controlling machining forces to prevent deformation, and achieving consistent surface quality across curved blades.

Machine Setup and Configuration for Impeller Machining

Proper machine setup is critical for optimizing impeller machining. Mikron’s five-axis machines feature robust designs with thermostabilized bodies, water-cooled direct drives, and high-dynamic spindles, ensuring thermal stability and vibration damping. Below are key setup considerations:

- Workholding: Use low-profile vises or custom fixtures to maximize tool access while maintaining rigidity. Palletized systems, like System 3R, enable automated loading for high-volume production.

- Spindle Selection: Choose high-speed spindles (12,000–60,000 RPM) with Step-Tec technology for fine surface finishes. For example, a 42,000 RPM spindle achieves Ra 0.4 μm in finishing operations.

- Tool Monitoring: Equip machines with Intelligent Tool Monitoring (ITM) and acoustic emission (AE) sensors to track tool wear and dressing, ensuring consistent performance.

- Thermal Management: Activate programmable warm-up cycles and OptiCool spindle technology to maintain dimensional accuracy during long cycles.

Calibration of axes using direct-path measuring systems ensures repeatability within ±1 μm, critical for impeller precision. The Operator Support System (OSS) can be configured to smooth axis movements, improving feed rates by up to 25%.

Toolpath Strategies for Complex Surface Machining

Effective toolpath planning is central to machining impellers. Mikron machines support advanced CAM systems (e.g., hyperMILL) for generating optimized toolpaths. Key strategies include:

- Flank Milling: Uses the side of the tool to machine blade surfaces, reducing cutting forces and improving surface finish. Suitable for semi-finishing, with step-over values of 0.1–0.2 mm.

- Point Milling: Employs the tool tip for finishing complex curves, ensuring high accuracy. Ball-end mills (Ø2–6 mm) are ideal, with a scallop height of 0.005–0.01 mm.

- Geodesic Toolpaths: Follow the impeller’s natural curvature (e.g., along blade veins) to minimize toolpath length and deviations. Blend or scallop modes with single guiding curves enhance finish quality.

- Rest Machining: Targets remaining material in tight areas after roughing, using smaller tools (Ø0.5–1 mm) to avoid sinker EDM reliance.

Toolpath optimization aims to minimize discrepancies between the tool envelope and target surface. For instance, maintaining a toolpath tolerance of 0.002 mm reduces machining errors by 40–70%. Dynamic Fixture Offset (DFO), Tilted Working Plane (TWP), and Tool Center Point Control (TCP) functions on Mikron machines ensure precise tool orientation.

Parameter Selection for Precision and Efficiency

Selecting appropriate machining parameters balances precision, surface quality, and cycle time. Below is a sample parameter set for impeller machining on a Mikron MILL S/X U machine:

| Operation | Tool Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Depth of Cut (mm) | Step-Over (mm) |

|---|---|---|---|---|---|

| Roughing | Ø10 End Mill | 12,000 | 2,000 | 0.5–1.0 | 0.3–0.5 |

| Semi-Finishing | Ø6 Ball Mill | 20,000 | 1,500 | 0.2–0.3 | 0.1–0.2 |

| Finishing | Ø2 Ball Mill | 42,000 | 800 | 0.05–0.1 | 0.01–0.05 |

Notes:

- Roughing prioritizes material removal with higher depths of cut to reduce cycle time.

- Finishing uses high spindle speeds and low step-over to achieve Ra 0.06 μm.

- Adjust feed rates based on material (e.g., titanium requires 30% lower feeds than aluminum).

Machining forces must be controlled to prevent thin-walled blade deformation. For example, milling forces should not exceed 100 N for titanium impellers to avoid deflections beyond 0.01 mm.

Integrating Milling and Grinding for Enhanced Surface Quality

Mikron’s MILL S/X U series uniquely combines milling and jig grinding in a single machine, reducing process steps and improving surface quality. The closed grinding process (grinding, dressing, measuring) achieves finishes of Ra 0.06 μm or better. Key features include:

- Grinding Setup: Integrated dressing spindles with AE sensors monitor tool condition, ensuring consistent grinding performance.

- Process Flow: Rough mill the impeller, then grind critical surfaces (e.g., blade tips) in the same setup to eliminate reclamping errors.

- Automation: Laser measuring systems and pallet changers enable rapid transitions between milling and grinding, reducing non-cutting time.

For impellers requiring mirror finishes, grinding can replace manual polishing, shortening production time by 20–30%.

Error Control and Deformation Mitigation

Impeller machining faces challenges from milling forces and toolpath deviations, which account for 40–70% of total errors. Strategies to mitigate these include:

- Force Prediction: Use CAM software to simulate milling forces and adjust parameters to keep deflections below 0.01 mm.

- Error Compensation: Apply software-based compensation to correct toolpath deviations, achieving tolerances within 1–5 μm.

- Tool Geometry: Use tapered ball-nose tools for tight areas to reduce interference and improve accuracy.

- Machine Dynamics: Leverage Mikron’s high-dynamic drives (1.7g acceleration, 61 m/min feed rate) to maintain stability during rapid movements.

Regular calibration of the machine’s kinematic chain ensures long-term precision, while predictive maintenance using AE sensors minimizes downtime.

Automation and Scalability for High-Volume Production

For high-volume impeller production, Mikron machines integrate seamlessly with automation systems like System 3R robots. Benefits include:

- Pallet Changers: Enable unattended operation, reducing labor costs and cycle times.

- Scalable Layouts: Add multiple machines to a single robot cell, increasing output per square meter.

- Real-Time Monitoring: Mikron’s miTool system provides dashboards for tool life and process optimization, improving efficiency by 15–20%.

Automation ensures consistent quality for batch sizes ranging from 50 to millions, as seen in applications like turbocharger impellers.

Practical Implementation and Case Example

Consider a titanium centrifugal impeller (Ø100 mm, 8 blades) machined on a Mikron MILL P 800 U S. The process involves:

- Roughing: Ø10 end mill, 12,000 RPM, 2,000 mm/min, 0.8 mm depth of cut, leaving 0.5 mm stock.

- Semi-Finishing: Ø6 ball mill, 20,000 RPM, 1,500 mm/min, 0.2 mm step-over, reducing stock to 0.1 mm.

- Finishing: Ø2 ball mill, 42,000 RPM, 800 mm/min, 0.01 mm step-over, achieving Ra 0.05 μm.

- Grinding: Integrated jig grinding for blade tips, using a Ø1 mm wheel, achieving Ra 0.04 μm.

Total cycle time is approximately 90 minutes, with automation reducing setup time by 50%. The impeller meets tolerances of ±3 μm and eliminates the need for sinker EDM, saving 5 hours per part.

Conclusion

Optimizing complex surface machining of impellers on Swiss Mikron five-axis machines requires a systematic approach to machine setup, toolpath planning, parameter selection, and process integration. By leveraging Mikron’s advanced features—high-speed spindles, thermal stability, and combined milling-grinding capabilities—manufacturers can achieve tight tolerances, superior surface finishes, and efficient production. The strategies outlined, supported by precise parameters and automation, ensure reliable, high-quality impeller machining for demanding applications.