At Kesu Hardware, we specialize in plastic rapid prototyping, offering one-stop manufacturing solutions to transform your ideas into high-quality prototypes. Based in Dongguan, China, our advanced facility leverages cutting-edge technologies such as silicone molding, 3D printing, CNC machining, and plastic injection molding to deliver precise prototypes with fast turnaround times. With no minimum order quantity (MOQ) and a focus on quality, we cater to industries like automotive, medical, electronics, and more.

Our extensive experience in plastic rapid prototyping ensures that every prototype meets your design specifications, enabling you to test functionality, validate designs, and accelerate product development. Whether you need a single prototype or small-batch production, Kesu Hardware is your trusted partner.

What is Plastic Rapid Prototyping?

Plastic rapid prototyping is a product development method that uses advanced manufacturing techniques to quickly produce plastic components for testing and evaluation. It allows engineers and designers to create multiple iterations of a part in a short time, facilitating hands-on review and refinement before moving to production. The process is characterized by its speed, affordability, and ability to mitigate risks by eliminating financial and time constraints associated with traditional manufacturing.

Rapid prototyping provides critical insights into design performance, helping engineers make informed decisions. Unlike final products, prototypes may not have the same durability or finish but are essential for validating form, fit, and function. Common processes include 3D printing, CNC machining, silicone molding (vacuum casting), and rapid injection molding.

Benefits of Plastic Rapid Prototyping

Plastic rapid prototyping offers numerous advantages for product development:

- Speed: Prototypes can be produced in 1-7 days, accelerating design cycles.

- Cost Efficiency: Low-cost processes reduce financial risks during testing.

- Design Flexibility: Test multiple designs and materials simultaneously.

- Risk Mitigation: Identify and address design flaws early.

- Material Versatility: Choose from a wide range of plastics like ABS, PEEK, and Nylon.

- Improved Product Quality: Iterative testing leads to better final products.

Applications of Plastic Rapid Prototyping

Our plastic rapid prototyping services support a variety of industries and applications, including:

- Automotive: Interior components, dashboard parts, and functional prototypes.

- Medical: Device housings, surgical tool prototypes, and biocompatible parts.

- Electronics: Enclosures, connectors, and consumer device components.

- Consumer Goods: Product casings, packaging prototypes, and aesthetic models.

- Industrial: Machinery components and tooling prototypes.

Our Plastic Rapid Prototyping Processes

Kesu Hardware offers a range of rapid prototyping processes to meet diverse project requirements. Each method is optimized for speed, precision, and cost-effectiveness, allowing us to deliver high-quality plastic prototypes tailored to your needs.

Silicone Molding (Vacuum Casting)

Silicone molding, also known as vacuum casting, is a cost-effective and fast method for producing small batches of plastic prototypes. It involves creating a silicone mold from a master prototype and injecting liquid plastic to form parts with excellent surface finish and detail.

- Process:

- Create a master prototype (e.g., via CNC machining using ABS).

- Produce a silicone mold around the master (dries in ~8 hours).

- Inject liquid plastic into the mold and cure.

- Remove the part; each mold supports ~20 parts.

- Materials: ABS, PP, PC, PMMA, POM, soft rubber, silicone rubber, heat-resistant materials.

- Lead Time: 3-7 days.

- Advantages: Low cost, high accuracy, suitable for small batches.

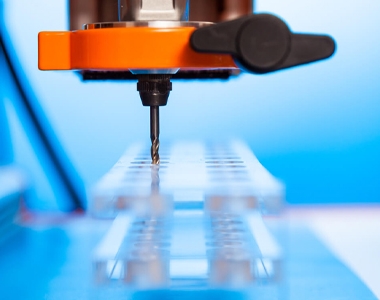

CNC Machining

CNC machining is a versatile process for plastic rapid prototyping, offering high precision and excellent surface quality. Our advanced 4-axis and 5-axis CNC machines ensure accurate replication of complex geometries, making it ideal for functional prototypes.

| Equipment Type | Quantity | Brand | Max Part Size |

|---|---|---|---|

| 5-Axis CNC Machines | 10 | Jingdiao/DMG Mori | D600 mm |

| 4-Axis CNC Machines | 20 | AutoCam | D600 x L1200 mm |

| 3-Axis CNC Machines | 50 | - | 1500 x 800 mm |

- Tolerances: ±0.01 mm for linear dimensions, ±0.02 mm for holes.

- Lead Time: 3-5 days.

- Advantages: High accuracy, excellent surface finish, suitable for complex designs.

3D Printing

3D printing is a popular choice for plastic rapid prototyping due to its speed and affordability. We offer multiple 3D printing technologies to suit different project needs:

- Stereolithography (SLA): High-resolution parts with smooth surfaces.

- Selective Laser Sintering (SLS): Durable nylon prototypes with complex geometries.

- Multi Jet Fusion (MJF): High-strength parts with fine details.

- Digital Light Processing (DLP): Fast production of small, detailed parts.

| Technology | Materials | Lead Time |

|---|---|---|

| SLA | Resin | 1-3 days |

| SLS | Nylon, SLS Nylon | 2-4 days |

| MJF | Nylon | 2-4 days |

| DLP | Resin | 1-3 days |

Plastic Injection Molding

Plastic injection molding is ideal for producing high-quality prototypes that closely resemble final production parts. While typically used for mass production, we offer rapid injection molding for prototyping with quick turnaround.

- Process: Inject molten plastic into a mold using an injection molding machine.

- Materials: ABS, PP, PC, PMMA, POM, Nylon.

- Lead Time: 7-14 days (including mold creation).

- Advantages: High repeatability, suitable for complex shapes.

Available Materials for Plastic Rapid Prototyping

The choice of material is critical to the performance of a plastic prototype. Kesu Hardware offers a wide range of plastics, each with unique properties to suit specific applications.

ABS

A low-cost plastic with good mechanical properties, widely used in automotive and electronics.

Colors: Natural, Black

Finish: Painting

Acetal (POM)

High stiffness and low friction, ideal for gears and bearings.

Colors: White, Black

Ceramics

High hardness and wear resistance, used in specialized applications.

Color: White

Delrin (POM)

Low-friction, high-toughness material with excellent dimensional accuracy.

Colors: White, Black

HDPE

Resistant to acids and solvents, used in plugs and seals.

Colors: Black, White

Nylon (PA6, PA66)

High resistance to friction and chemicals, ideal for wear-resistant parts.

Colors: White, Black, others

Polycarbonate (PC)

Heat- and impact-resistant, used in manufacturing and electronics.

Colors: Clear, Black, Glossy

Polyethylene (PE)

Resistant to acids and alkalis, used in injection molding.

Colors: Black, White

PEEK

High-precision material resistant to moisture, chemicals, and high temperatures.

Types: German Imported, Japan Imported

Color: Opaque Beige

PMMA (Acrylic)

Scratch-resistant, used for optical and display applications.

Colors: Optically Clear, Opaque

Polypropylene (PP)

Chemical-resistant with good fatigue strength, used in lab equipment.

Colors: White (semi-clear or opaque)

PTFE (Teflon)

Slippery, high-temperature-resistant material for low-friction applications.

Colors: Black, White (opaque)

SLS Nylon

Durable material for 3D printing, offering flexibility and strength.

Color: White

Tolerance Standards for Plastic Prototypes

We adhere to ISO 2768-M standards for plastic parts, ensuring precise tolerances for various dimensions and features.

| Nominal Length (mm) | Tolerance (mm) |

|---|---|

| 0.5 to 3 | ±0.1 |

| Over 3 to 6 | ±0.2 |

| Over 6 to 30 | ±0.3 |

| Over 30 to 120 | ±0.5 |

| Over 120 to 400 | ±0.8 |

| Over 400 to 1000 | ±1.2 |

| Over 1000 to 2000 | ±2.0 |

| Feature | Tolerance (mm) |

|---|---|

| Linear Dimensions | ±0.05 |

| Diameter | ±0.02 |

| Precise Hole | ±0.02 |

| Flatness | ±0.01 |

| Angular Dimensions | ±1º |

Surface Finishes for Plastic Prototypes

We offer a variety of surface finishes to enhance the aesthetics and functionality of your plastic prototypes:

- Polishing: Glossy, mirror-like surfaces for optical clarity.

- Painting: Custom colors for aesthetic appeal.

- Silk Screen Printing: Precise labeling and branding.

- Sandblasting: Uniform texture for improved adhesion.

- Vapor Polishing: Enhances clarity for transparent materials like PC and PMMA.

Quality Assurance

Our commitment to quality is backed by advanced inspection equipment and rigorous processes:

| Equipment | Quantity | Brand |

|---|---|---|

| Coordinate Measuring Machine (CMM) | 2 | LEAD |

| XRF Spectrometer | 1 | HITACHI |

| 2.5D Measuring System | 3 | - |

| Calipers | 20 | - |

| Micrometers | 10 | - |

Every prototype undergoes thorough inspection to ensure compliance with ISO 2768-M standards and your specifications.

Why Choose Kesu Hardware?

Kesu Hardware is a trusted leader in plastic rapid prototyping, offering unmatched expertise and capabilities:

- Large Facility: 8,000+ square meters of manufacturing space.

- Extensive Clientele: Serving 3,000+ customers globally.

- High Production Capacity: 500,000+ parts produced annually.

- Skilled Team: 200+ employees, including 30+ engineers.

- Advanced Equipment: 200+ machines, including 5-axis CNC and 3D printers.

FAQ: Plastic Rapid Prototyping

What is plastic rapid prototyping?

Plastic rapid prototyping is a process that uses advanced manufacturing techniques like 3D printing, CNC machining, and silicone molding to quickly produce plastic components for testing and design validation.

What processes do you offer for plastic prototyping?

We offer silicone molding (vacuum casting), 3D printing (SLA, SLS, MJF, DLP), CNC machining, and plastic injection molding.

What materials are available?

We work with ABS, Acetal, Ceramics, Delrin, HDPE, Nylon, PC, PE, PEEK, PMMA, PP, PTFE, and SLS Nylon, among others.

What are your lead times?

Lead times vary: 1-3 days for 3D printing, 3-7 days for silicone molding and CNC machining, and 7-14 days for injection molding.

How can I request a quote?

Upload your 2D and 3D drawings with material, finish, and quantity details to our website or email us for an instant quote.