Compressor impellers are critical components in turbomachinery, requiring high precision to ensure aerodynamic performance, structural integrity, and operational efficiency. Manufacturing these complex geometries involves advanced techniques such as laser processing and CNC machining. This article provides a detailed, technical comparison of the precision capabilities of these two methods, focusing on their processes, tolerances, surface quality, and suitability for impeller production. The analysis is grounded in practical data and industry-standard metrics to offer a reliable and systematic evaluation for engineers and manufacturers.

Overview of Compressor Impeller Manufacturing

Compressor impellers, often referred to as working wheels, are the core components of centrifugal compressors. They consist of a hub, blades, and a wheel cover, with intricate geometries such as twisted blades and rounded corners at the root. These features demand precise machining to achieve optimal airflow, pressure increase, and dynamic balance. Both laser processing and CNC machining are employed to meet these requirements, but they differ significantly in their approach, precision, and application.

Laser processing uses a high-powered laser beam to cut or shape materials through thermal energy, offering a non-contact method. CNC machining, in contrast, relies on physical cutting tools controlled by computer numerical control to remove material. The choice between these methods depends on factors such as precision requirements, material properties, and production scale. Below, we compare their precision capabilities in the context of compressor impeller manufacturing.

Laser Processing for Compressor Impellers

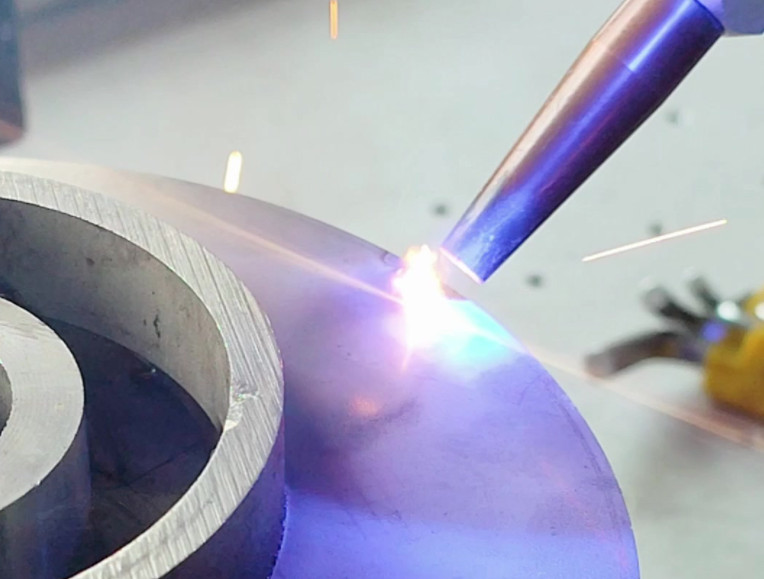

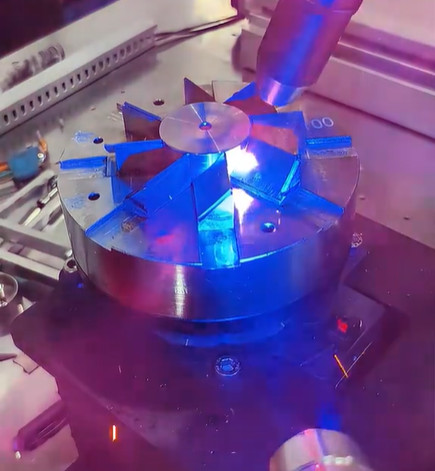

Laser processing employs a focused, high-energy laser beam to cut, engrave, or shape materials. For compressor impellers, laser cutting is primarily used for profiling blades and flow channels, particularly in materials like stainless steel, titanium, and aluminum. The process is controlled by CNC systems, ensuring repeatability and precision for complex designs.

The laser beam, typically generated by CO2 or fiber laser sources, is focused to a spot size as small as 0.1 mm, enabling intricate cuts with minimal material waste. The non-contact nature of laser processing reduces mechanical stress on the workpiece, which is critical for maintaining the structural integrity of thin or delicate impeller blades. The process involves directing the laser beam through optics, with assist gases (e.g., oxygen or nitrogen) to remove molten material and enhance cutting efficiency.

Precision Metrics:

- Tolerance: Laser processing achieves tolerances as tight as ±0.05 mm for impeller blade profiles, suitable for aerospace-grade components.

- Surface Roughness: Surface roughness values typically range from Ra 0.8 to 1.6 µm, ensuring smooth flow surfaces that minimize turbulence.

- Cutting Speed: Laser cutting can achieve speeds up to 114 inches per minute (IPM) for thin materials like 1 mm stainless steel, reducing production time.

- Heat-Affected Zone (HAZ): The thermal process creates a HAZ, which may alter material properties near the cut edge, with a typical width of 0.1–0.5 mm depending on laser power and material.

Applications in Impeller Manufacturing: Laser processing excels in cutting thin impeller blades and intricate flow channels, particularly for prototypes or small-batch production. Its ability to handle complex geometries without custom tooling makes it ideal for custom designs. However, limitations include reduced effectiveness for thick materials (e.g., >20 mm) and potential thermal distortion in sensitive alloys.

CNC Machining for Compressor Impellers

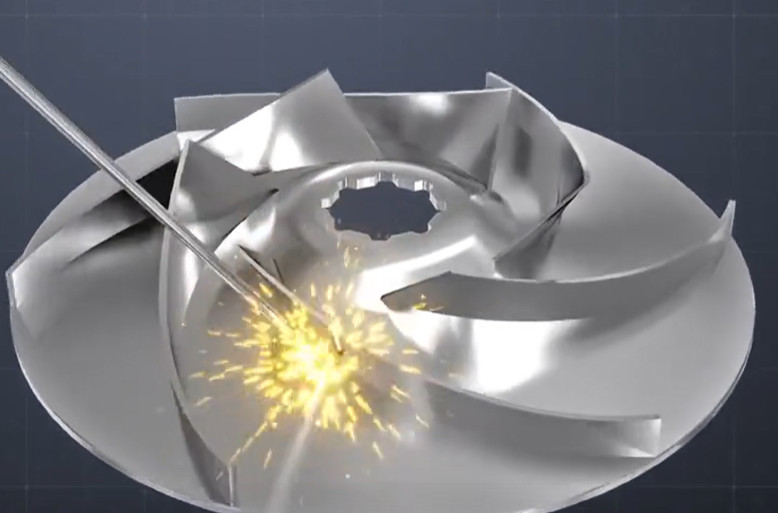

CNC machining for compressor impellers typically involves 5-axis milling, which allows for the precise shaping of complex geometries like twisted blades and deep flow channels. The process uses rotating cutting tools, such as ball-end mills or tapered ball-end mills, to remove material from a solid blank, often a forging made of aluminum, stainless steel, or titanium.

Modern 5-axis CNC machining centers, equipped with high-speed spindles (up to tens of thousands of RPM) and advanced CAM software (e.g., UG NX, HyperMill), enable precise control over toolpaths. This ensures accurate blade curvature and hub geometry, critical for aerodynamic performance. The process begins with roughing to remove excess material, followed by finishing to achieve tight tolerances and smooth surfaces.

Precision Metrics:

- Tolerance: CNC machining achieves tolerances of ±0.01 to ±0.002 mm for critical features like blade profiles and hub surfaces, surpassing laser processing in high-precision applications.

- Surface Roughness: Surface roughness values can reach Ra 0.4 to 0.8 µm after fine milling, ideal for mirror-like finishes required in high-performance impellers.

- Cutting Speed: CNC milling is slower than laser cutting, typically achieving 70 IPM for similar materials, due to the physical contact and multiple passes required.

- Material Removal Rate: CNC machining excels in removing large volumes of material, with roughing tools capable of removing up to 500 cm³/min for aluminum.

Applications in Impeller Manufacturing: CNC machining is preferred for producing monolithic impellers from forgings, especially for high-stress applications in aerospace and industrial compressors. Its ability to handle thick materials and complex 3D geometries makes it suitable for large-scale production and components requiring precise dimensional control.

Precision Comparison: Key Metrics

The precision of laser processing and CNC machining for compressor impellers can be compared across several key metrics, including dimensional accuracy, surface quality, repeatability, and material compatibility. The following table summarizes these metrics based on typical industry standards.

| Metric | Laser Processing | CNC Machining |

|---|---|---|

| Tolerance (mm) | ±0.05 | ±0.01 to ±0.002 |

| Surface Roughness (Ra, µm) | 0.8–1.6 | 0.4–0.8 |

| Cutting Speed (IPM) | Up to 114 | Up to 70 |

| Material Thickness (mm) | Effective up to 20 | Effective for >20 |

| Repeatability | High (CNC-controlled) | Very High (CNC-controlled) |

| Heat-Affected Zone | 0.1–0.5 mm | None |

Analysis: CNC machining offers superior dimensional accuracy and surface quality, making it the preferred choice for impellers requiring ultra-tight tolerances and polished surfaces. Laser processing, however, provides faster cutting speeds and excels in thin materials and intricate designs. The absence of a HAZ in CNC machining is a significant advantage for materials sensitive to thermal distortion, such as titanium alloys.

Material Considerations for Impeller Manufacturing

Compressor impellers are typically made from materials like aluminum, stainless steel, titanium, or non-metallic composites, depending on the compressor’s operating conditions. The choice of manufacturing method impacts precision based on material properties.

Laser Processing: Laser cutting is highly effective for thin materials (e.g., 1–10 mm stainless steel or aluminum). Fiber lasers are preferred for metals due to their energy efficiency and ability to cut reflective materials. However, for titanium, which is prone to thermal stress, careful control of laser parameters is required to minimize HAZ effects.

CNC Machining: CNC machining is versatile across a wide range of material thicknesses and types. For example, 5-axis machining centers can process titanium impellers with thicknesses exceeding 20 mm, achieving precise blade curvature and hub geometry. The use of high-speed spindles and coated carbide tools ensures minimal material damage and consistent surface quality.

Material-Specific Precision: For aluminum impellers, CNC machining achieves tolerances of ±0.005 mm, while laser processing is limited to ±0.05 mm. For titanium, CNC machining maintains superior control over surface roughness (Ra 0.4 µm) compared to laser processing (Ra 1.2 µm).

Process Constraints and Considerations

While both methods offer high precision, certain constraints must be considered when selecting the appropriate process for compressor impeller manufacturing.

Laser Processing Constraints:

- Thermal Effects: The HAZ can alter material properties, potentially affecting fatigue strength in high-stress impeller applications.

- Thickness Limitations: Laser cutting struggles with materials thicker than 20 mm, requiring multiple passes or alternative methods.

- Maintenance: Laser systems require regular calibration of optics and laser sources to maintain precision, increasing operational costs.

CNC Machining Constraints:

- Tool Wear: Physical cutting tools experience wear, requiring frequent replacement or sharpening, which can affect long-term precision.

- Setup Time: CNC machining requires complex setup and programming, particularly for 5-axis operations, increasing lead times for small batches.

- Material Removal Rate: While effective for roughing, CNC machining is slower for intricate finishing compared to laser processing.

These constraints highlight the importance of aligning the manufacturing method with the impeller’s design requirements, material properties, and production scale.

Practical Applications and Case Studies

Laser Processing Case Study: In the production of a small-batch aerospace impeller (material: 1.5 mm stainless steel), laser cutting achieved a blade profile tolerance of ±0.05 mm with a cutting speed of 100 IPM. The process eliminated the need for custom tooling, reducing costs by 20% compared to CNC machining. However, post-processing was required to address minor HAZ effects, adding 10% to the production time.

CNC Machining Case Study: For a titanium impeller used in an industrial compressor (material thickness: 25 mm), 5-axis CNC machining achieved a tolerance of ±0.002 mm and a surface roughness of Ra 0.6 µm. The process used a ball-end mill with a spindle speed of 20,000 RPM, ensuring precise blade curvature. The total machining time was 30% longer than laser processing for thinner materials, but the absence of thermal effects ensured superior material integrity.

Conclusion

The choice between laser processing and CNC machining for compressor impeller manufacturing depends on specific project requirements, including precision, material thickness, and production scale. Laser processing offers high speed and precision for thin materials and intricate designs, achieving tolerances of ±0.05 mm and surface roughness of Ra 0.8–1.6 µm. However, its thermal effects and limitations with thick materials make it less suitable for certain applications. CNC machining, particularly 5-axis milling, provides superior precision (±0.01 to ±0.002 mm) and surface quality (Ra 0.4–0.8 µm), making it ideal for high-stress, thick-material impellers. By understanding the strengths and constraints of each method, manufacturers can optimize impeller production for performance and efficiency.